Insulator equivalent salt density optical fiber test method based on particle swarm support vector machine

A technology of support vector machine and equivalent salt density, which is applied in the field of value salt density optical fiber detection and value salt density detection, can solve the problems of low efficiency, real-time online detection, etc., and avoid economic loss and the harsh environment of live measurement , reduce pollution flashover accidents, save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

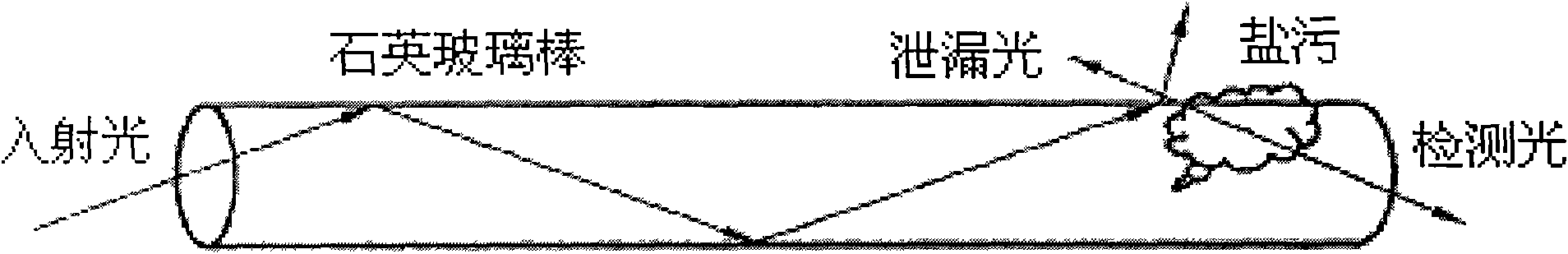

Method used

Image

Examples

Embodiment

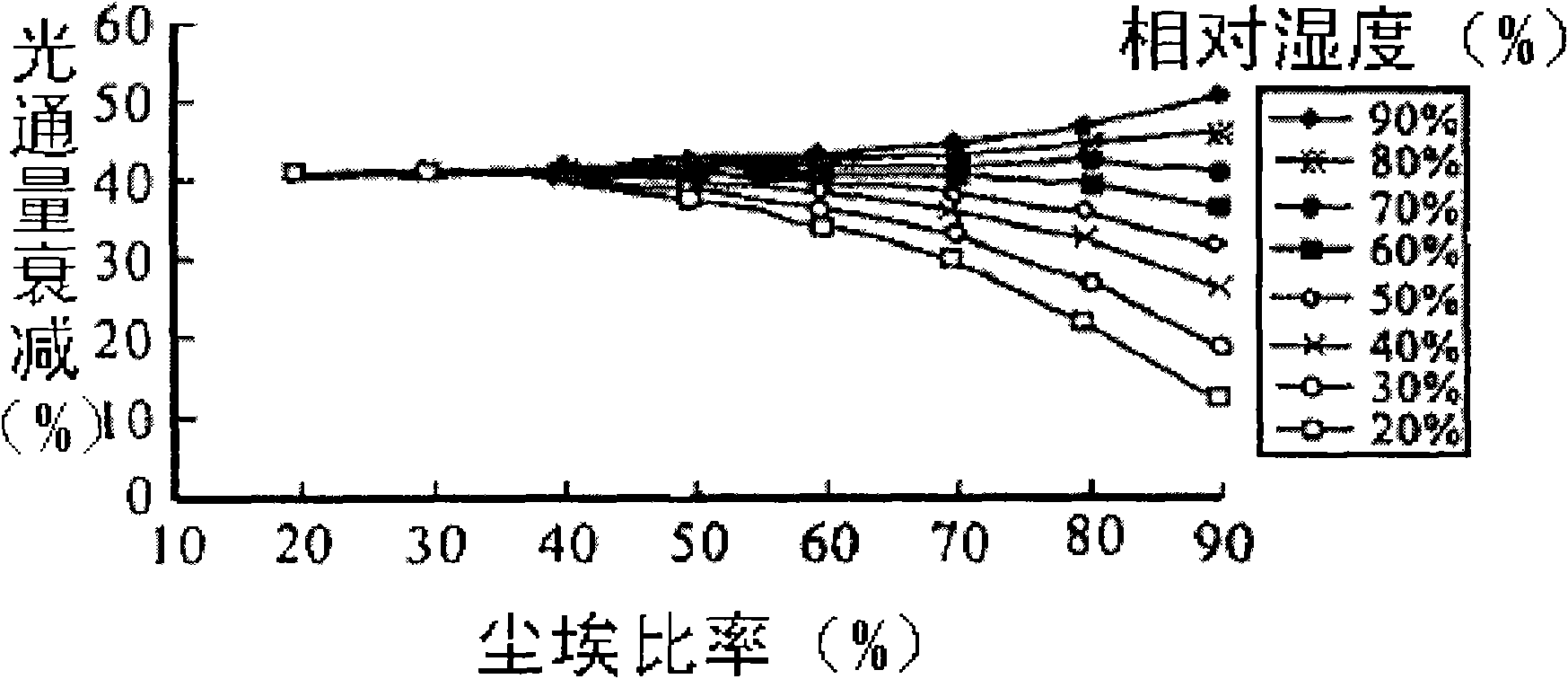

[0076] Step 1: Install the detection system that has been fully tested in the laboratory on a 110KV high-voltage transmission line, and the insulator is a suspension glass insulator LXP-160. The on-site detection device detects the luminous flux attenuation at five different time pointsΦ 1 and ambient relative humidity RH, as shown in Table 1.

[0077] Table 1 Luminous flux attenuation Φ at five different time points 1 and ambient relative humidity RH

[0078]

[0079] Attenuate the luminous flux Φ 1 , The relative humidity RH is transmitted to the management computer through wireless communication;

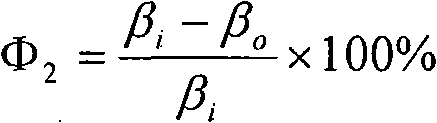

[0080] Step 2: Management computer receives luminous flux attenuation Φ 1 And the data information of relative humidity RH, the attenuation of luminous flux Φ 1 Perform normalized preprocessing according to the following formula to obtain the luminous flux attenuation Φ after normalized preprocessing2 :

[0081] Φ 2 = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com