System for regulating and optimizing smoke by power generation and recycle of residual heat of sintering ring cold machine

A technology for sintering annular coolers and circulating flue gas, which is applied to machines/engines, steam generation methods using heat carriers, waste heat treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

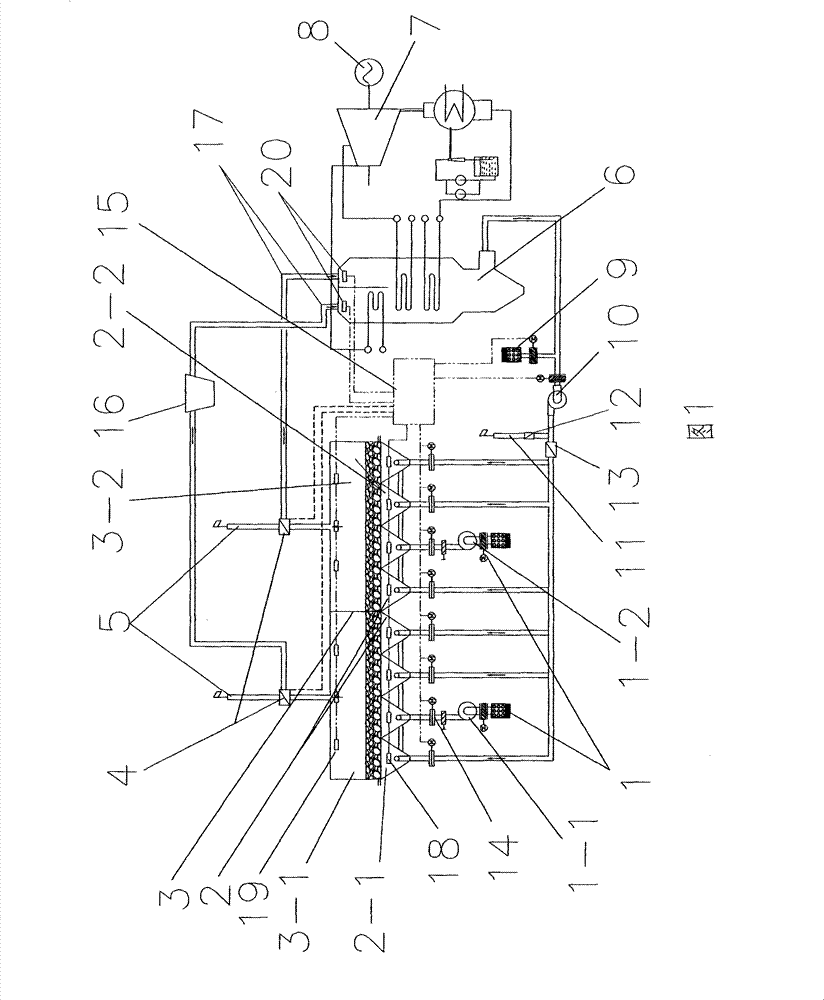

[0018] Such as figure 1 As shown, a sintered annular cooler waste heat power generation cycle flue gas optimization and adjustment system provided in this embodiment mainly includes: annular cooler 1, annular cooler bellows 2, annular cooler air chamber 3, and switching baffle door 4 , chimney 5, double-pressure non-supplementary combustion waste heat boiler 6, double-pressure supplementary steam condensing steam turbine 7, generator 8, supplementary damper 9, circulation fan 10, bypass chimney 11, bypass chimney damper 12, circulation fan outlet valve 13 , the circulating flue gas regulating damper 14, the control system 15, the air chamber 3 of the annular cooler is divided into a high temperature air chamber 3-1 and a low temperature air chamber 3-2, and the high temperature air chamber 3-1 and the low temperature air chamber 3-2 pass through the air intake The flue 17 is respectively connected to the dual-pressure non-supplementary combustion waste heat boiler 6, the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com