Hot water generating device of compound ferrite porcelain solar heat collection field

A technology for solar heat collection and power generation devices, applied in solar thermal power generation, solar thermal devices, solar heat collectors, etc., can solve the problem of complex structure and manufacturing process of vacuum glass tube heat collectors, easy corrosion of metals, and attenuation of sunlight absorption rate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

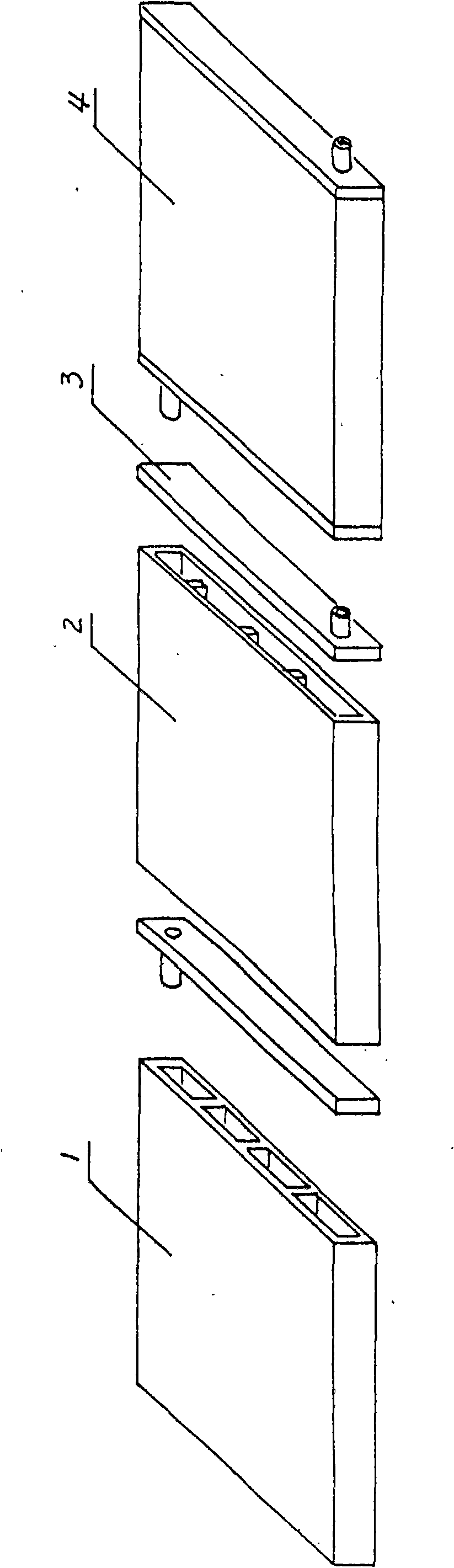

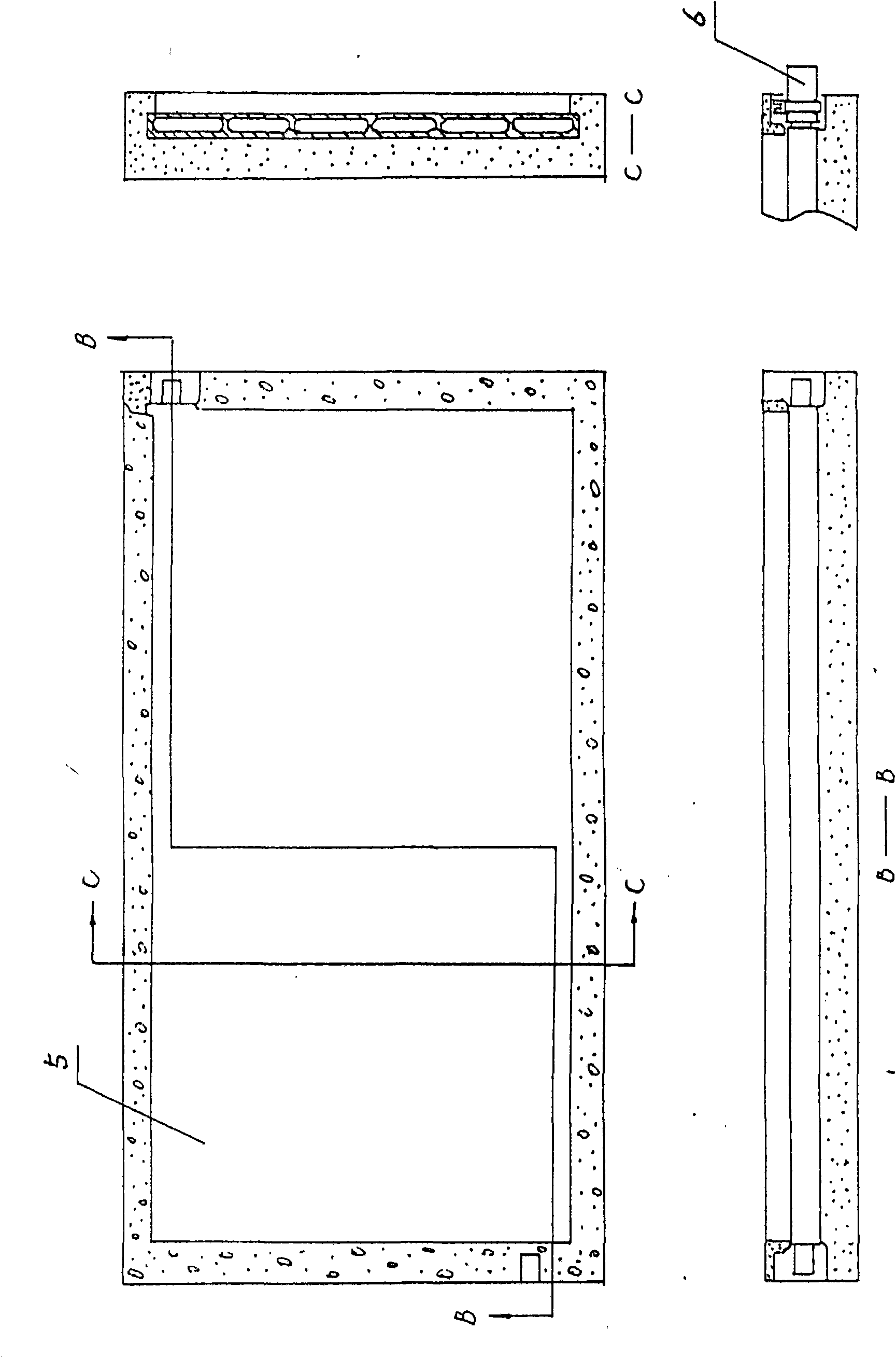

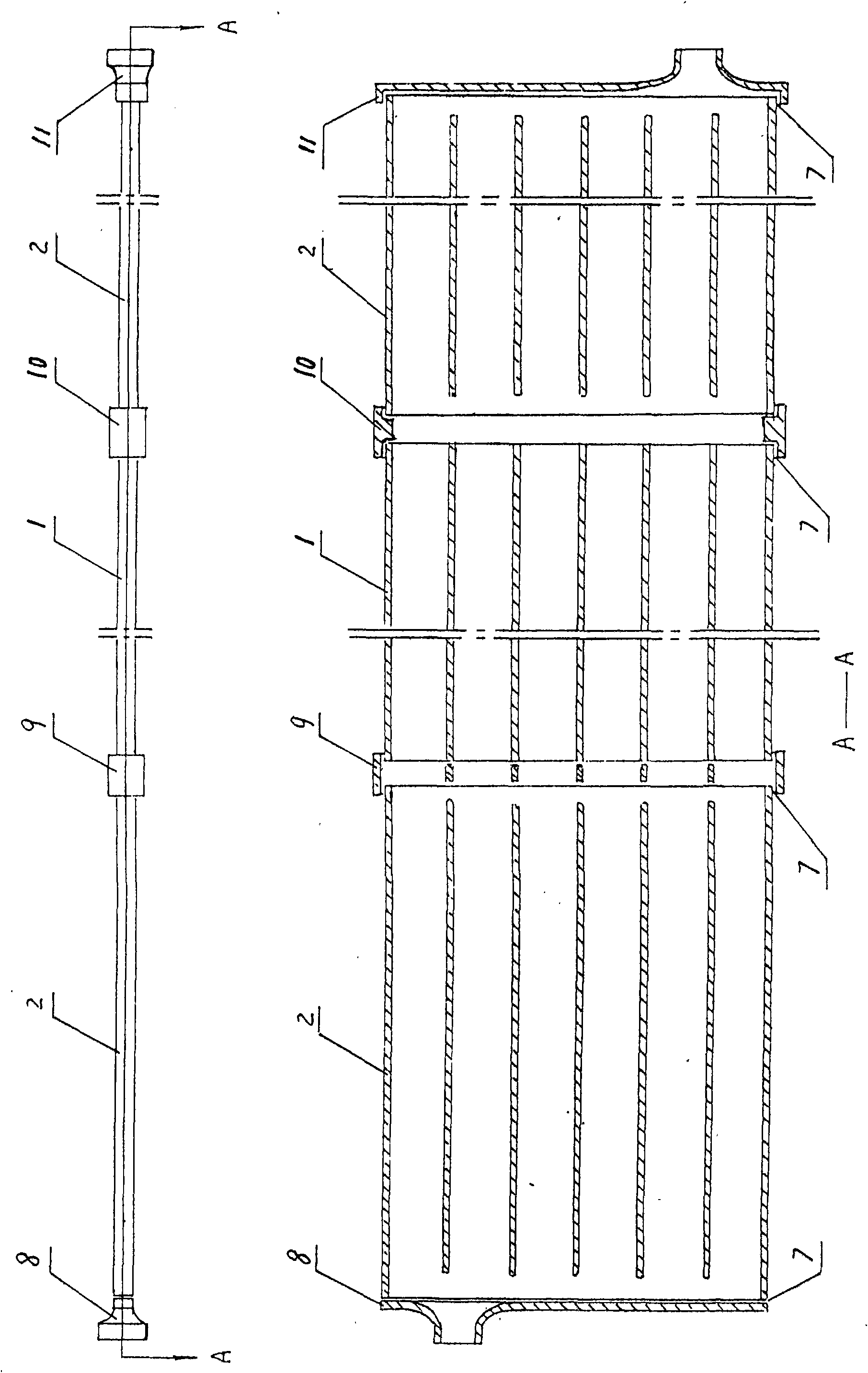

Method used

Image

Examples

Embodiment

[0059] 1. Build a ceramic solar heat collector field hot water power generation device in the barren beach, wasteland, and desert in the sunny area, build a windbreak forest around the heat collector field, and use a trencher to dig a ditch along the east-west direction. The length of the ditch is 200m, and there are 100 sections in total. Each section is 5m apart, and the section of the ditch is an inverted triangle. The excavated soil, stones, and sand are placed on the ground on the sunny side of the ditch, accumulated to form a slope, and integrated with the ditch slope to form a slope with an inclination angle of 30 degrees. On the sunny slope, the slope is 10m long, and the north and south slopes are flattened and compacted. On the back of the sunny slope, a second ditch is opened at a distance of 3m from the accumulation. The horizontal channel is 3m wide. , pour concrete along the slope top and bottom of the ditch, lay water pipes, spray rigid polyurethane foam with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com