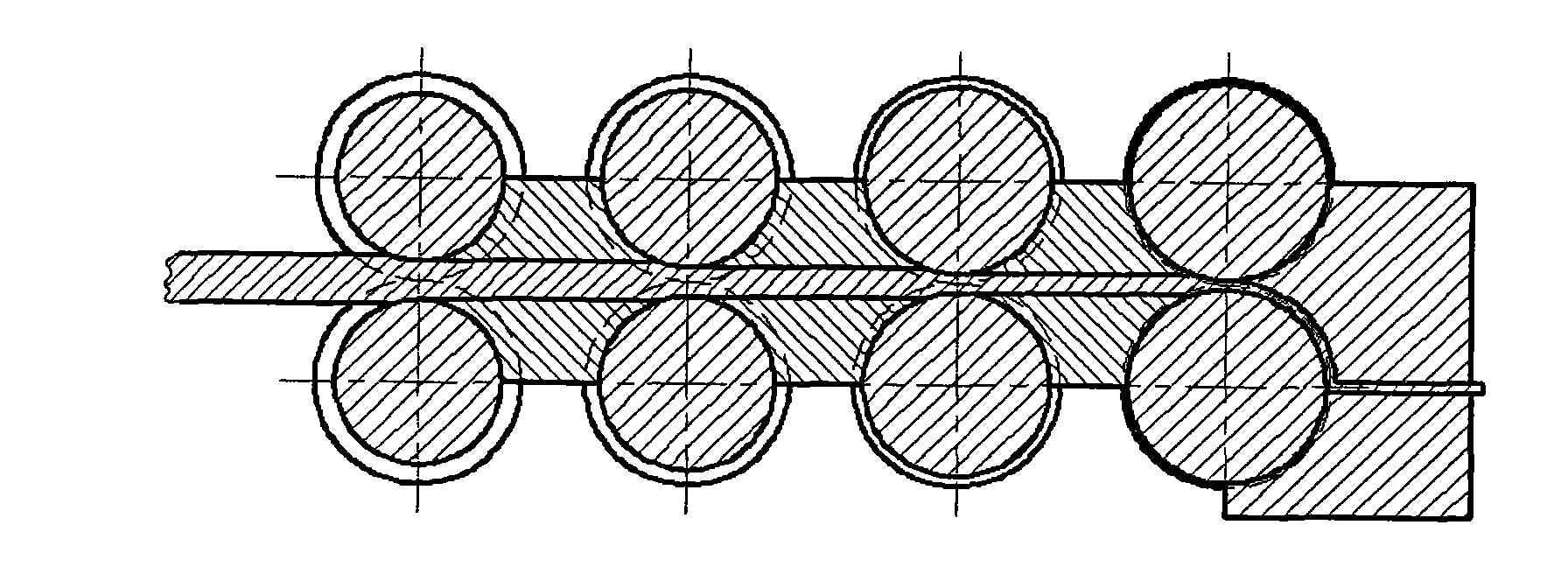

Metal material large-strain processing method based on multi-pair wheel rolling and equal channel corner extrusion

A technology of equal channel corners and processing methods, which is applied in the field of cold processing of metal materials, can solve problems such as the difficulty of continuous production and the inability to industrialize production, the small degree of texture orientation control of deformed materials, and the difficulty of achieving the equivalent large strain of the cross-section. The effect of reducing, reducing fracture and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: The billet is made of annealed industrial pure aluminum, wherein the rolling strain amount is 1.75 (the reduction amount is 80%), and the ECAP strain amount is 0.8. After deformation processing, the dislocation density of the material is 0.13 × 10 14 m -2 , the yield strength is increased by 60%, and the hardness is increased by 46%.

Embodiment 2

[0023] Example 2: The billet is made of annealed 5052 aluminum, the rolling strain is 0.4 (the reduction amount is 50%), and the ECAP strain is 0.8. After deformation processing, the dislocation density of the material is 2.636×10 14 m -2 , the yield strength is increased by 140% and the hardness is increased by 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com