Rubber coating forming mould

A molding die and encapsulation technology, applied in the field of encapsulation molding die, can solve the problems of lowering product yield, damage to functional areas such as functional layers, scratching of metal molds, etc., so as to reduce production defects, improve molding effect, and achieve good electrical conductivity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

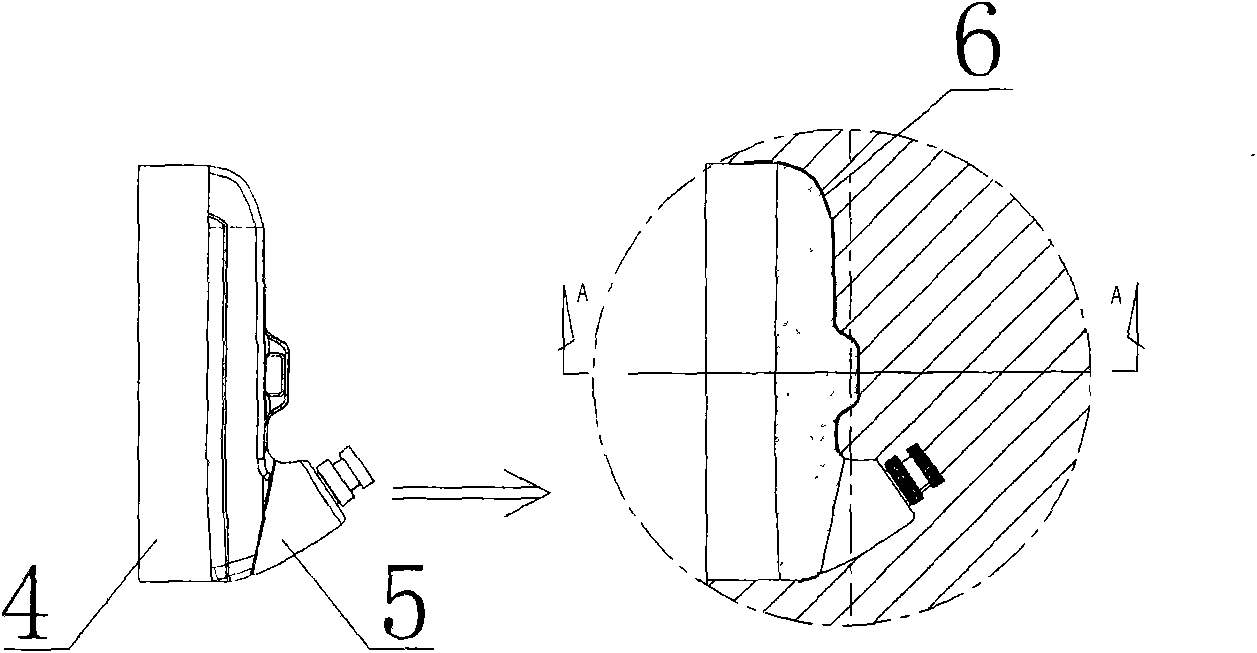

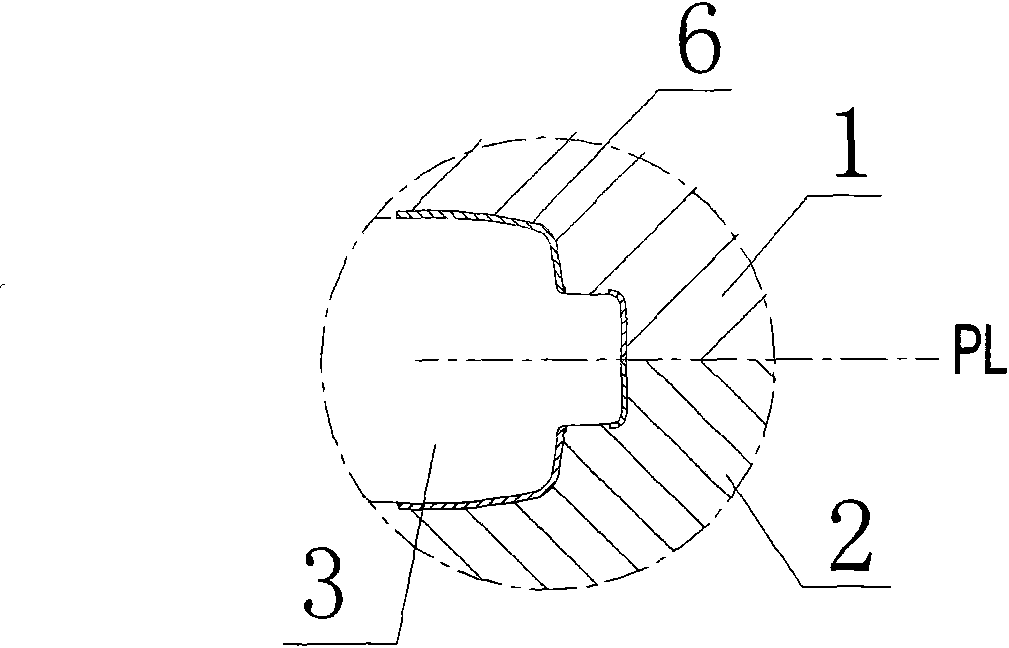

[0011] see figure 1 and figure 2 Shown, a kind of overmolding molding mold of the present invention, its structure comprises upper mold 1, and the lower mold 2 that cooperates with upper mold 1, and the mold cavity 3 that is arranged on upper mold 1 and lower mold 2, and with The mold cavity 3 matches the insert 4, and the rubber layer 6 is provided at the contact between the mold cavity 3 and the product 5. Since the rubber layer 6 is provided at the contact between the cavity 3 and the product 5, when the product is reprocessed through the mold, the product will not be scratched or crushed by the metal mold in the mold, which effectively improves the molding effect ; It can reduce the temperature in the mold, protect the product, improve the yield of processed products, and because the functional layer on the product is not damaged, good functions are guaranteed and production defects are reduced.

[0012] Wherein, the thickness of the rubber layer 6 is 1-2MM, which plays...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com