Air cylinder detachable type shield

A protective cover and detachable technology, which is applied in the direction of mechanical equipment, engineering safety devices, welding accessories, etc., to improve the availability, prevent the welding strength from not conforming to the process, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically described below in conjunction with the accompanying drawings.

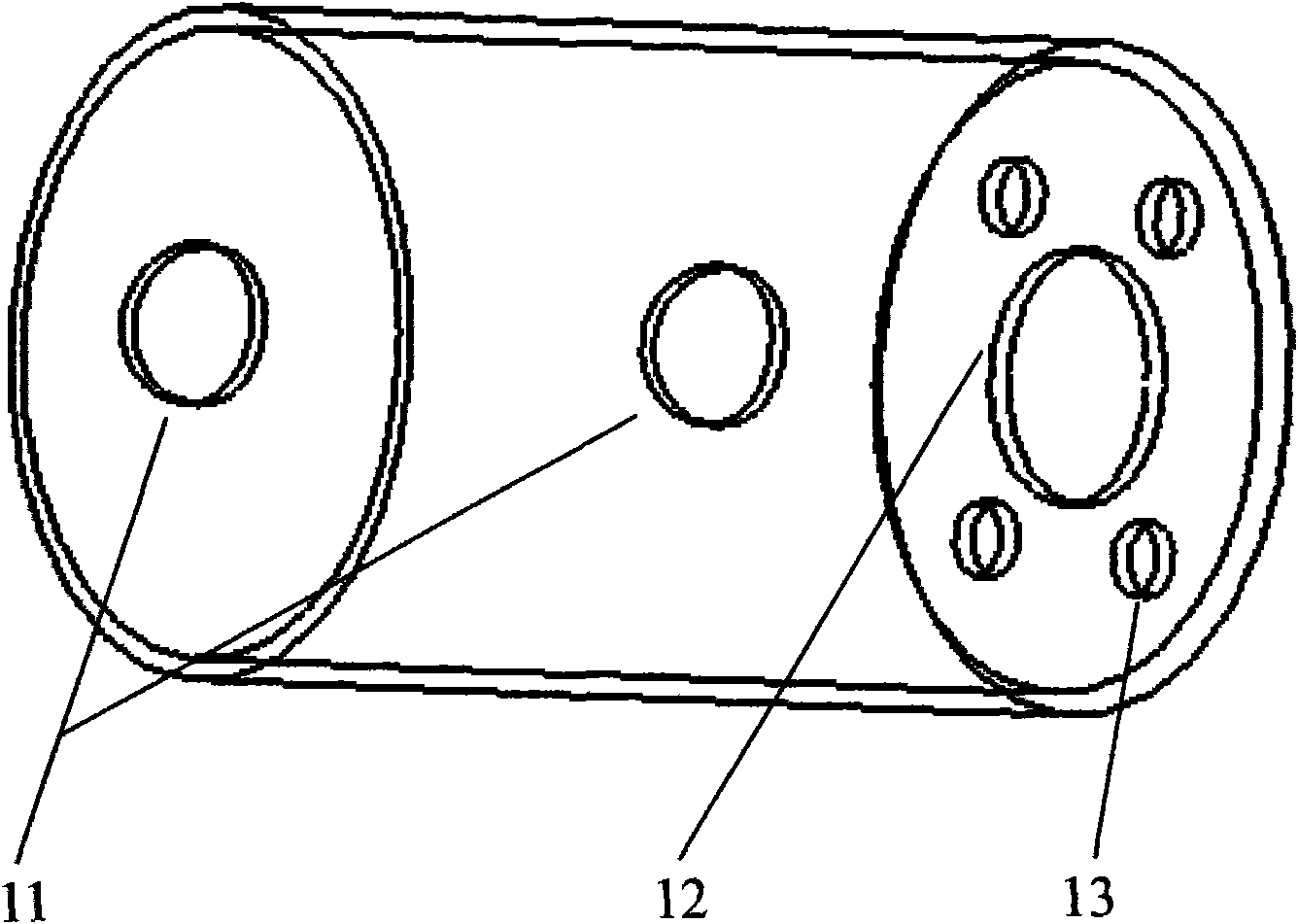

[0028] Figure 2-4B The structure of the detachable protective cover is shown in , the protective cover 1 is roughly a cylinder, and the cylinder piston rod installation hole 12 and four protective cover installation fastening holes 13 are opened on its end surface, and on the cylindrical surface of the protective cover Have joint installation hole 11; The size of protective cover size and the position of joint installation hole are designed and manufactured according to the size of cylinder, and material selects flexible insulating material for use, as: PVC soft board, polyurethane etc.

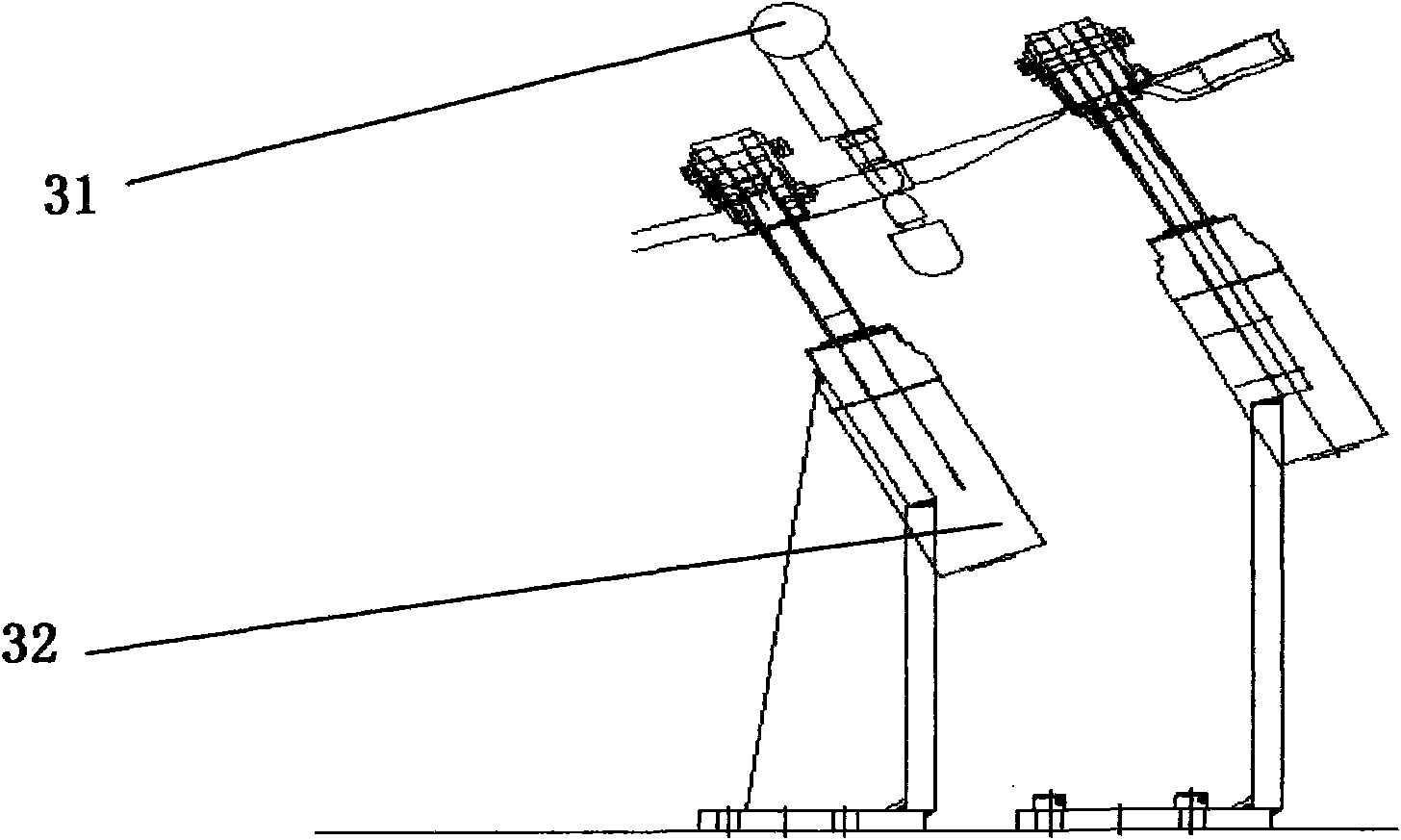

[0029] combined with Figure 5A , 5B To describe the installation of the protective cover 1. As shown in the figure, first remove the cylinder connector 21, put the detachable protective cover 1 of the cylinder on the body of the cylinder 2, and adjust the protective cover 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com