Method and device for cleaning a component, particularly of a vaporizer of a condenser device and a washer or washer/dryer comprising such a device

A technology of condensing device and evaporator, which is applied in the field of washing machine/dryer or tumble dryer, evaporator of condensing device, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

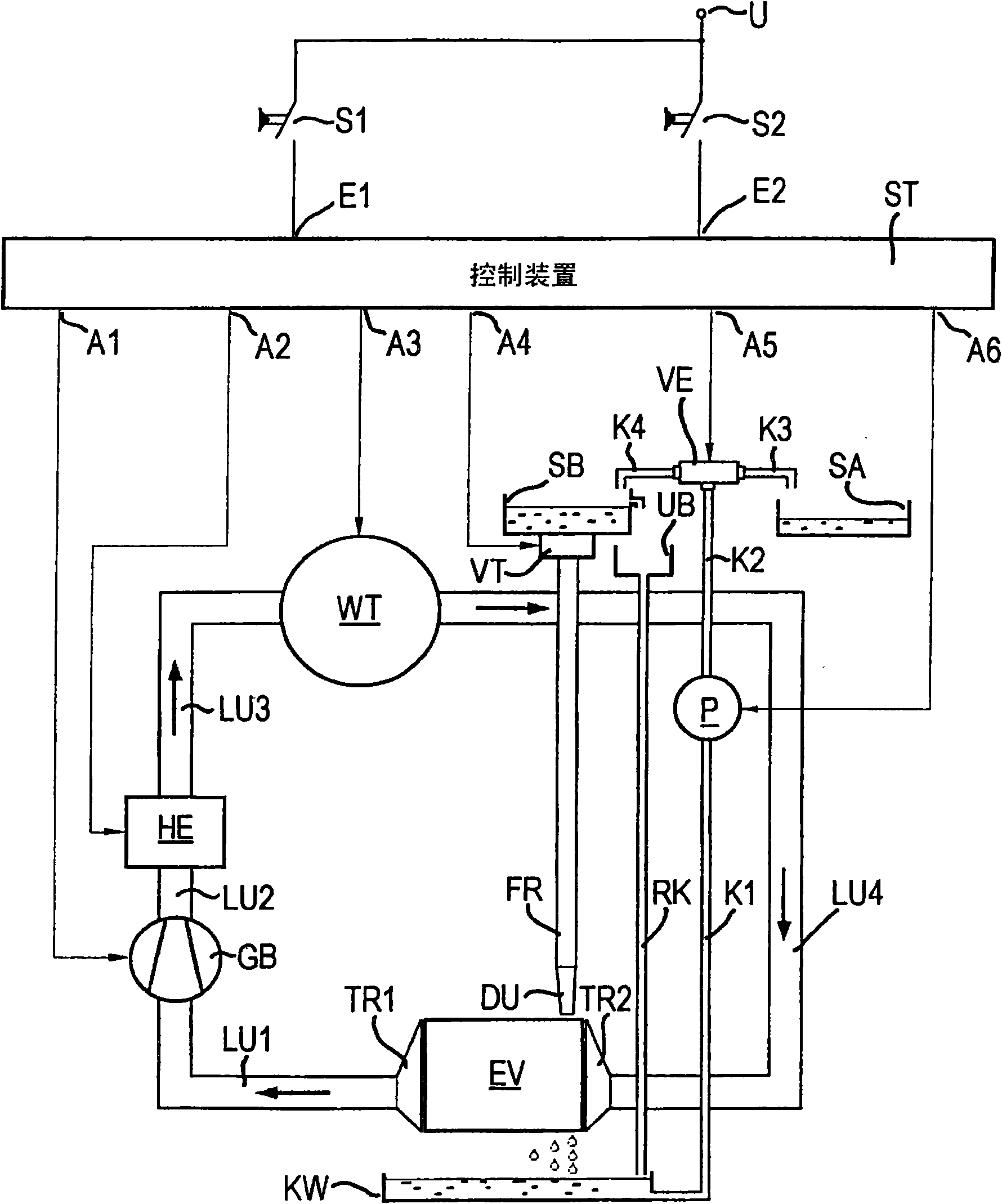

[0029] figure 1 An apparatus according to one embodiment of the invention, shown schematically in figure 1 The components shown are only those components that are important to the understanding of the invention. These components include firstly the washer / dryer or tumble dryer drum WT containing the wet laundry to be dried, and the process air flow structure connected to said drum, which will be described in more detail below ground analysis, the process air along figure 1 flow in the direction indicated by the arrow.

[0030] The process air flow structure comprises a series of process air ducts LU1, LU2, LU3 and LU4 and the means connected to these ducts, namely the fan GB, the heating means HE and the condensing means which are not shown in any more detail in this figure. Evaporator EV. In this case, the evaporator EV is connected on its outlet side via a funnel-shaped connection TR1 acting as a transition to one end of a process air duct LU1 to which cold dry process a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com