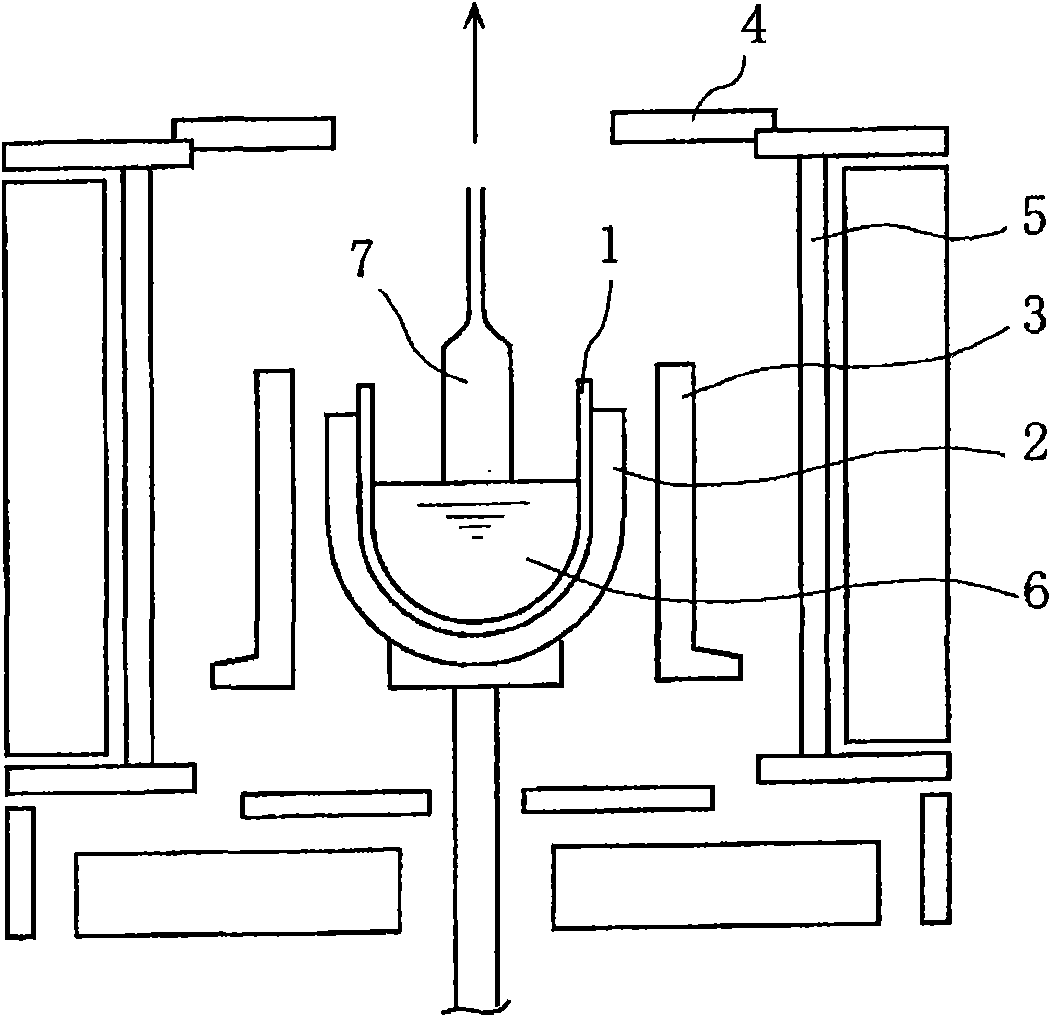

Method for protecting carbonaceous crucible and single crystal pulling apparatus

A crucible and carbonaceous technology is applied in the protection field of carbonaceous crucibles, which can solve the problems of poor workability, long working time, damage to the expanded graphite film, etc., and achieve the effects of good shape followability, shortened working time and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

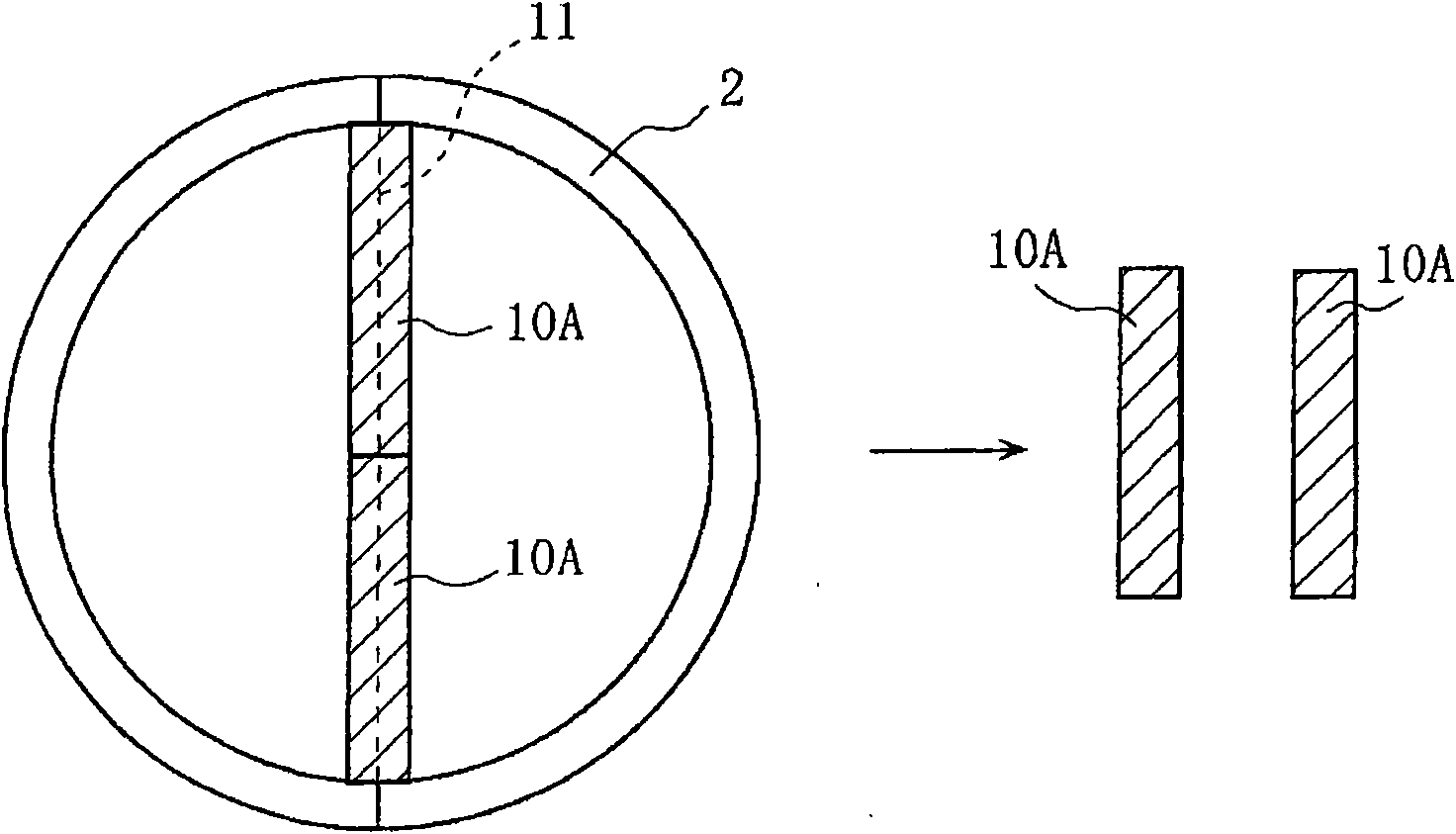

Embodiment 1

[0048] The same graphite crucible (graphite crucible divided in two) as the above-described embodiment has a size of 22 inches, and the protective film sheet (hereinafter referred to as the present invention) divided into two by the same method as the above-mentioned embodiment is made. The diaphragm A1) was laid along the butt joint of the graphite crucible, and 50 real machine tests of the CZ device were carried out. At this time, the time (working time) for laying the protective film on the graphite crucible, the ratio (failure rate) and the durability of the graphite crucible caused by the damage of the protective film were measured, and the results are shown in Table 1. Show.

[0049] [Table 1]

[0050] Types of membrane (diaphragm)

Embodiment 2

[0052] The size of the graphite crucible is 40 inches, and a protective film (hereinafter referred to as the film A2 of the present invention) divided into two of the corresponding size is used. In addition, under the same conditions as in Example 1 A real machine test was carried out to measure the operating time, failure rate and durability, and the results are shown in Table 1.

Embodiment 3

[0058] The same C / C crucible as in the above-described embodiment has a size of 22 inches, and the protective film (hereinafter referred to as the film B1 of the present invention) divided in the same manner as in the above-mentioned embodiment is used to cover the C / C crucible entirely. 50 real machine tests of the CZ device were carried out. At this time, the time for laying the protective film on the C / C crucible (working time), the ratio of the protective film damaged and unable to be used (failure rate), and the durability of the C / C crucible were measured, and the results As shown in table 2.

[0059] [Table 2]

[0060] Types of membrane (diaphragm)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com