Method for producing reforming feedstock by light and medium gasoline distillates

A technology for light fractions and raw materials, applied in the field of producing catalytic reforming raw materials, can solve the problems of harsh operating conditions, consumption of hydrogen sources, complicated processes, etc., and achieve the effects of avoiding waste water treatment, simplifying operating procedures, and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

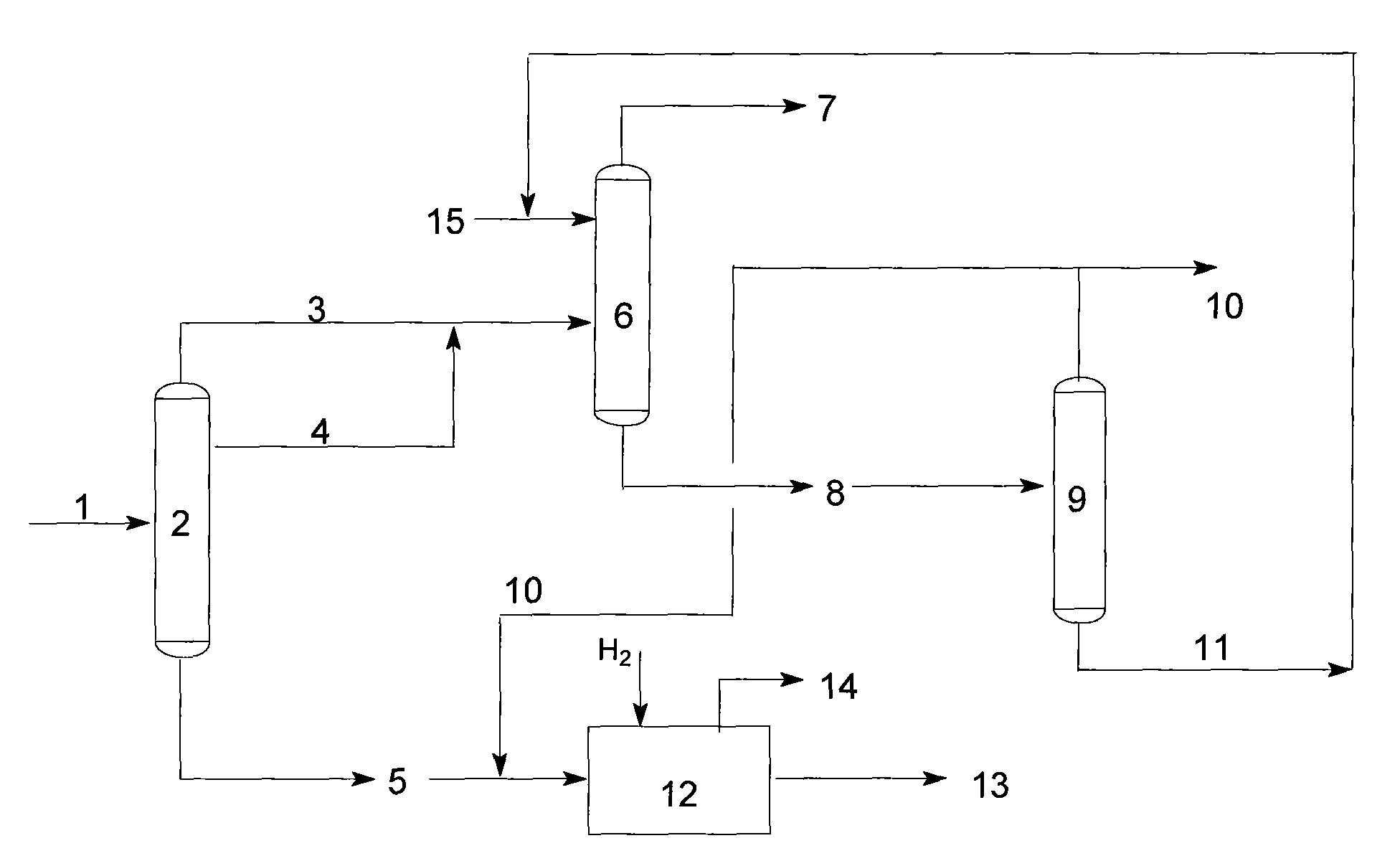

Method used

Image

Examples

Embodiment 1

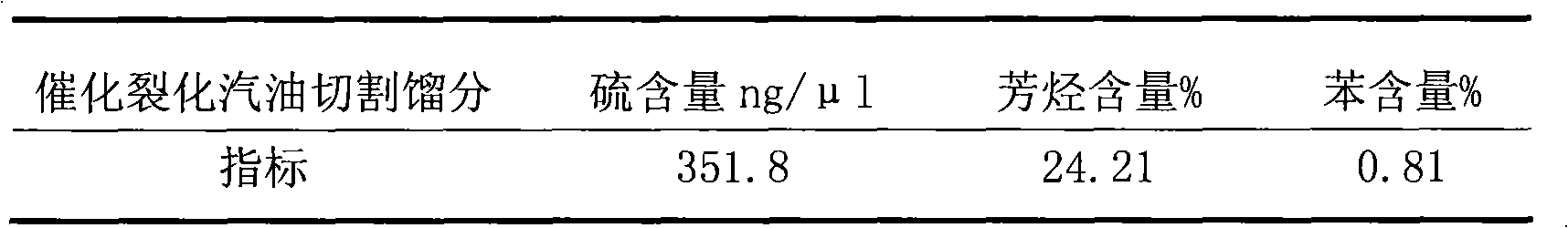

[0027] The first step, fractionation prefabrication of FCC gasoline light and mid-distillate feedstock

[0028] FCC gasoline 1 with a sulfur content below 1000ppm and an aromatics content below 40% from the catalytic cracking unit is sent to the middle part of the pre-fractionation tower 2, and the light fraction 3 of the catalytic cracking gasoline fractionated by the pre-fractionation tower is discharged from the top of the tower, and the catalyst The middle distillate 4 of the cracked gasoline is extracted from the side line in the upper part of the tower. The light distillate and the middle distillate with a distillation range of FCC gasoline below 170°C will be used as raw materials for the next extraction and rectification. The heavy distillate 5 of FCC gasoline with a distillation range higher than 170°C Discharged from the bottom of pre-fractionation tower 2, will be used as raw material for hydrodesulfurization;

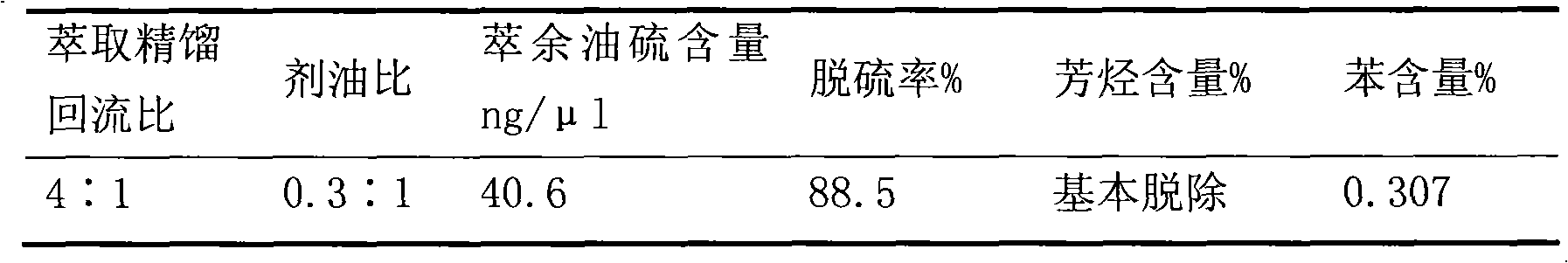

[0029] The second step is the extraction, rectificatio...

Embodiment 2

[0040] The volume ratio of the light fraction and the middle fraction of the extraction agent to the catalytic cracking gasoline is changed to 1:1, the reflux ratio is changed to 5:1, and the operating temperature of the extractive distillation tower is changed to 50-80°C at the top of the tower and 121°C at the bottom of the tower. ~ 125 DEG C, other technological operating conditions are all the same as embodiment 1. The product indicators after extraction and rectification treatment are: the sulfur content of raffinate oil is 16ng / μl, and the content of benzene and aromatics is not detected.

Embodiment 3

[0042] The volume ratio of the light fraction and the middle fraction of the extraction agent to the catalytic cracking gasoline is changed to 0.7:1, the reflux ratio is changed to 4:1, and the operating temperature of the extractive distillation tower is changed to 50-82°C at the top of the tower and 110°C at the bottom of the tower. ~115 ℃, other process operating conditions are all the same as embodiment 1. The product indicators after extraction and rectification treatment are: the sulfur content of the raffinate is 30ng / μl, the aromatics content is not detected, and the benzene content is a trace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com