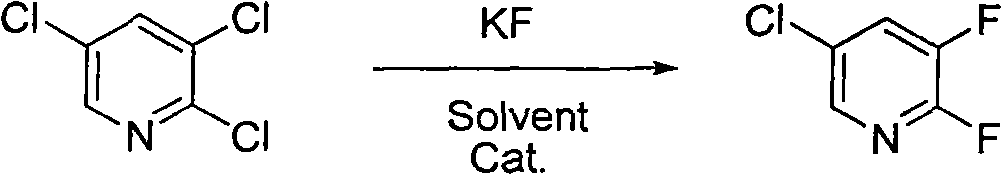

Synthesis method of 2,3-difluoro-5-chloropyridine

A synthetic method, the technology of chloropyridine, applied in 2 fields, can solve the problem of high price, achieve simple operation and solve the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 2,3,5-Trichloropyridine (18.2g, 0.1mol), potassium fluoride (13.9g, 0.24mol, pre-vacuum-dried at 140°C for 12 hours) were dissolved in 50mL sulfolane, under nitrogen protection, heated to 120°C, Added 1.2 g of tetraphenylphosphine bromide, maintained at 180°C for 5 hours, and then maintained at 200°C for 12 hours. According to gas phase analysis, the yield of 2,3-difluoro-5-chloropyridine was 39.1%, and the conversion rate of 2,3,5-trichloropyridine was 99%.

Embodiment 2

[0026] 2,3,5-Trichloropyridine (18.2 g, 0.1 mol), potassium fluoride (17.4 g, 0.3 mol, pre-vacuum-dried at 140°C for 12 hours) were dissolved in 100 mL of N-methylpyrrolidone, protected by argon. Heated to 120°C, added 2.0 g of tetrabutylphosphine bromide, maintained at 185°C for 7 hours, and then maintained at 205°C for 15 hours. According to gas phase analysis, the yield of 2,3-difluoro-5-chloropyridine was 42%, and the conversion rate of 2,3,5-trichloropyridine was 100%.

Embodiment 3

[0028] 2,3,5-Trichloropyridine (18.2g, 0.1mol), potassium fluoride (23.1g, 0.4mol, pre-vacuum-dried at 140°C for 12 hours) were dissolved in 100mL N-methylpyrrolidone, protected by argon, Heated to 120°C, added 1.0g of tetrabutylphosphine bromide, maintained at 190°C for 10 hours, and then maintained at 205°C for 10 hours, the yield of 2,3-difluoro-5-chloropyridine was 40%, 2 , What is the conversion rate of 3,5-trichloropyridine 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com