Firing resistant conveying belt for metal screen and method for producing same

A production method and metal mesh technology, applied in the field of conveying conveyor belts, can solve problems such as low service life and poor high temperature resistance, and achieve the effects of increased service life, low strength loss and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

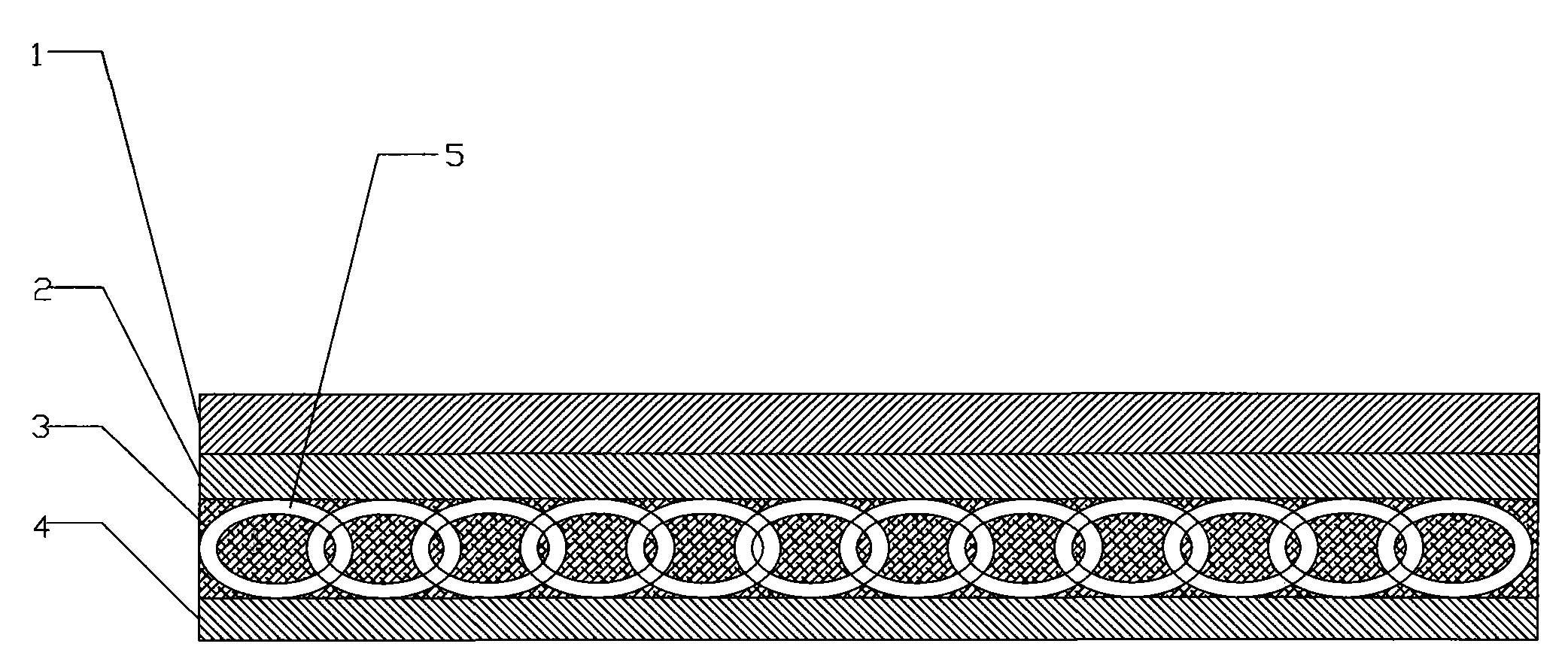

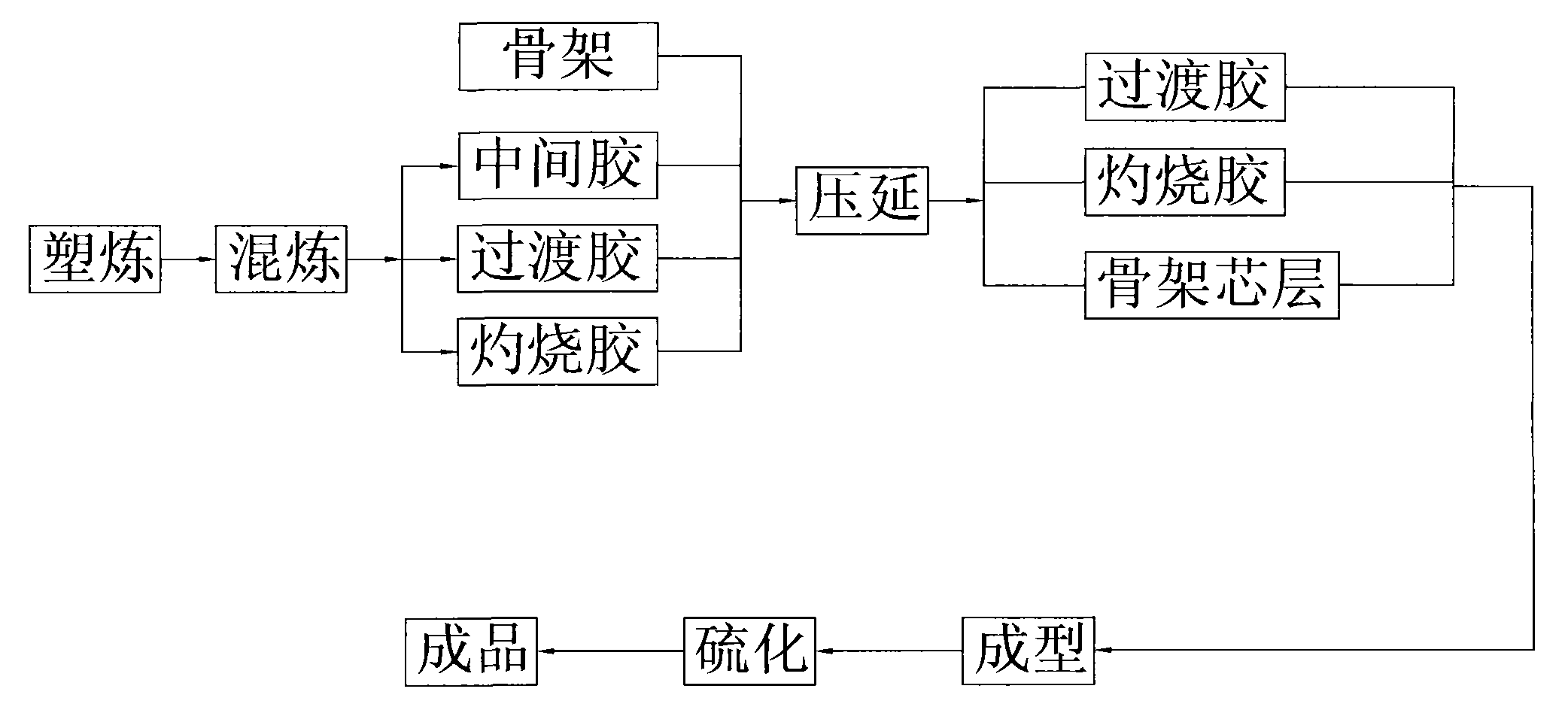

[0052] Such as figure 1 The specific embodiment of the present invention shown is a metal mesh fire-resistant conveyor belt, including a skeleton core layer, and a heat-resistant strong transition layer 2 coated on the outer surface of the skeleton core layer, and on the upper surface of the heat-resistant strong transition layer 2 Covered with a high-temperature burning-resistant surface layer 1, the skeleton core layer is composed of a metal spiral mesh integral belt core 4 and an intermediate rubber layer 3 squeezed into the metal spiral mesh integral belt core 4, and the high-temperature burning-resistant surface layer 1 Consists of the following materials in proportions by weight:

[0053] 60 parts of EPDM rubber, 40 parts of neoprene rubber, 1.2 parts of accelerator TMTD, 1.8 parts of accelerator CZ, 2.0 parts of vulcanizing agent TAIC, 12 parts of zinc oxide, 4 parts of magnesium oxide, 1 part of stearic acid, carbon black 40 parts of N220, 20 parts of pentaerythritol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com