Method for recovering iron concentrates from alumina red mud

A technology for iron ore concentrate and iron recovery, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of loss of magnetic minerals, affecting the recovery rate of iron minerals, etc. The effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

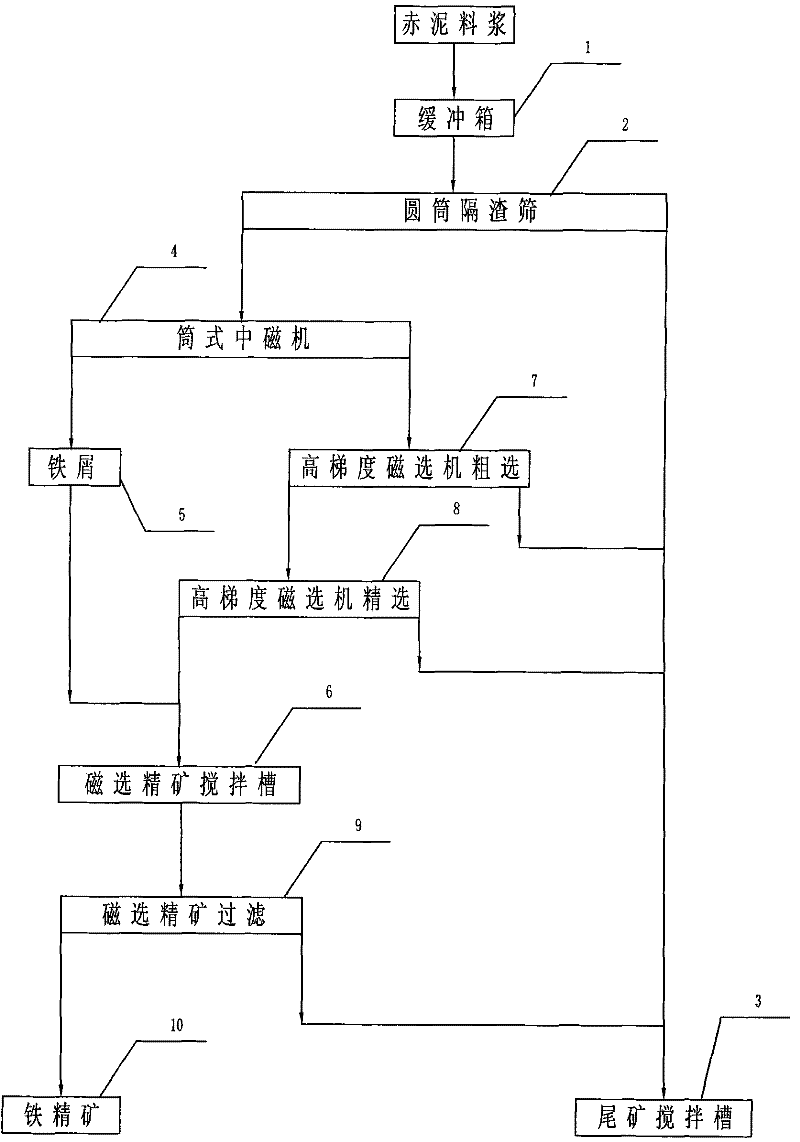

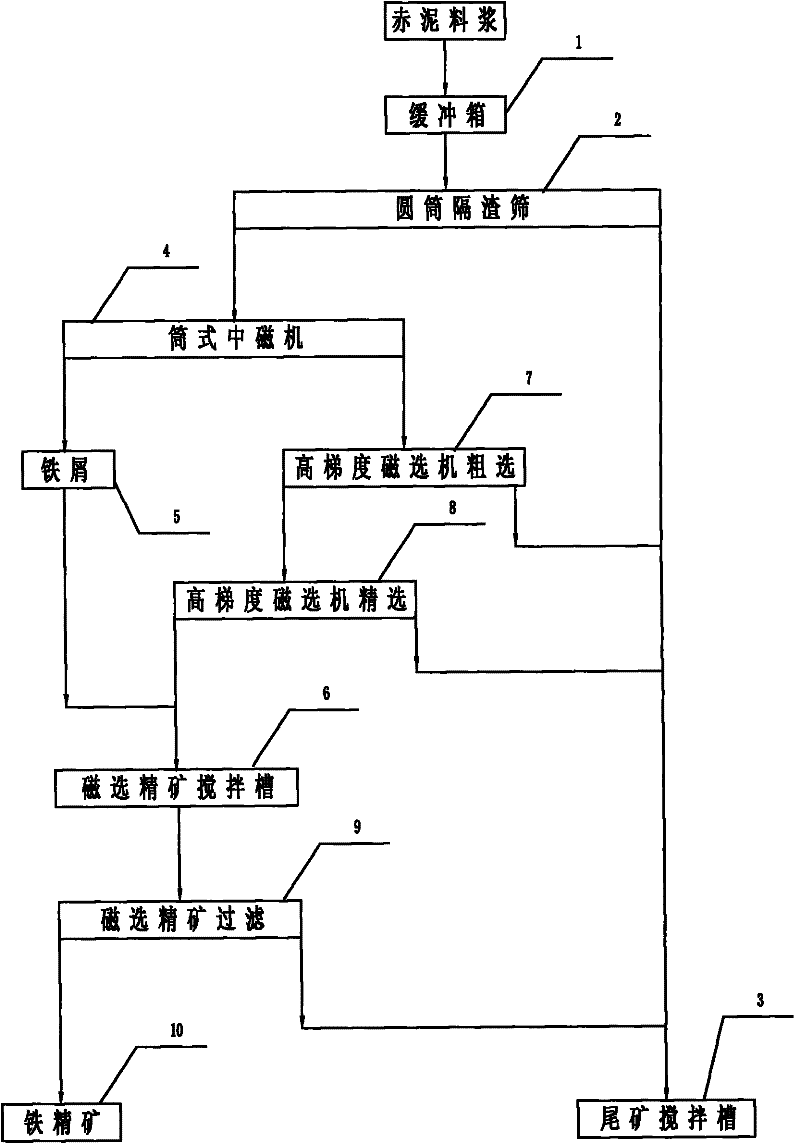

[0021] The red mud slurry from the alumina plant with an iron content of 18-35% and a concentration of 35-40% is first sent to the buffer tank 1, and after being diluted with some hot water in the buffer tank 1, the slurry has a concentration of 30-34% The slurry flows into the cylindrical slag separation screen 2 to remove impurities such as ground washing water and sundries introduced in the alumina production process, and the impurities flow to the tailings mixing tank 3 by itself. After removing impurities, the red mud slurry flows into the drum type magnetic machine 4 to select a small amount of iron filings 5 (mainly magnetite), and the selected small amount of iron filings 5 are washed with hot water and then flow directly into the concentrate mixing tank 6. The tailings of the drum-type magnetic machine 4 are self-flowed to the roughing slon vertical ring pulsating high-gradient magnetic separator 7 for roughing, and the background field strength is set to 1.00T, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com