Flat cable

A flat cable and cable body technology, applied in the direction of flat/ribbon cables, insulated cables, communication cables, etc., can solve the problems of inability to manufacture flexible flat cables, complicated manufacturing methods, and increased costs, and achieve high-quality electrical characteristics, control Effect of characteristic impedance, flexibility and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

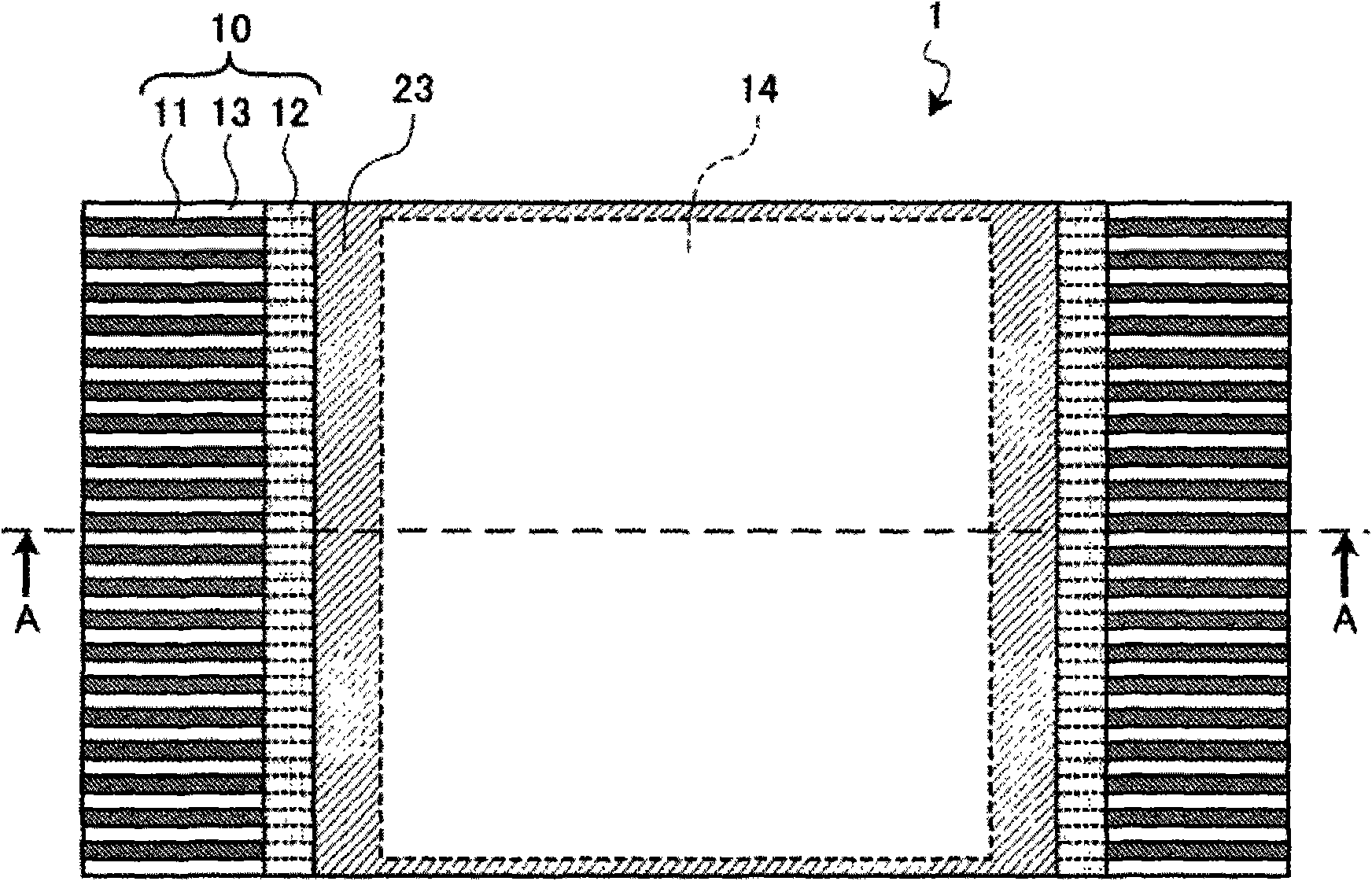

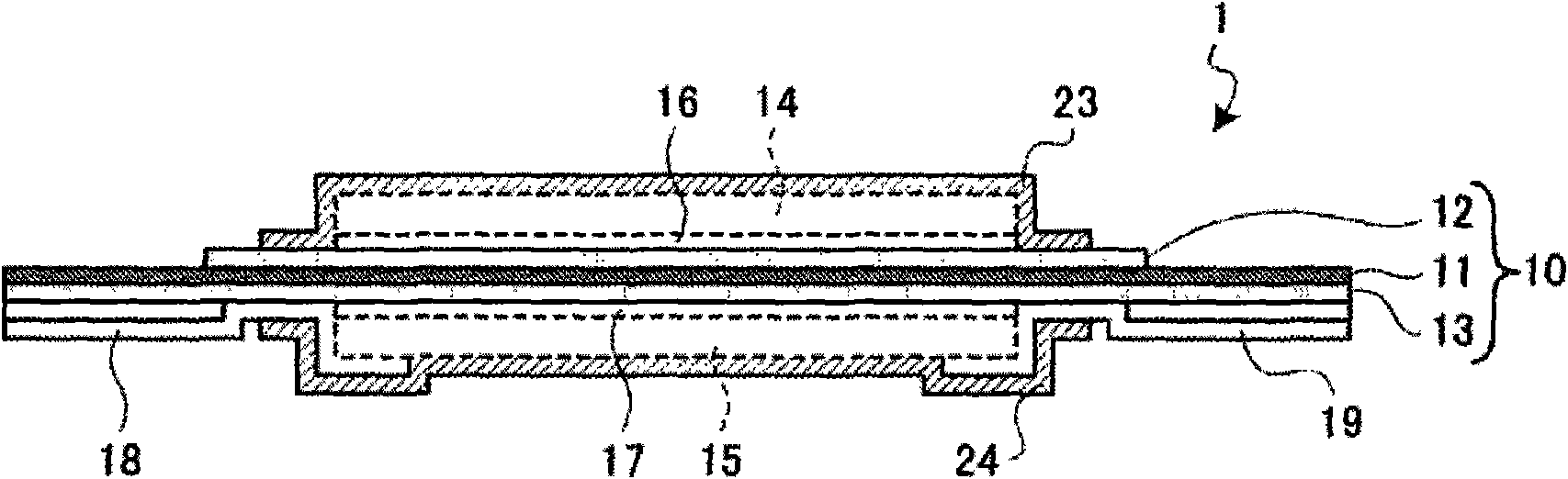

Embodiments of the flexible flat cable of the present invention will be described below based on experimental results.

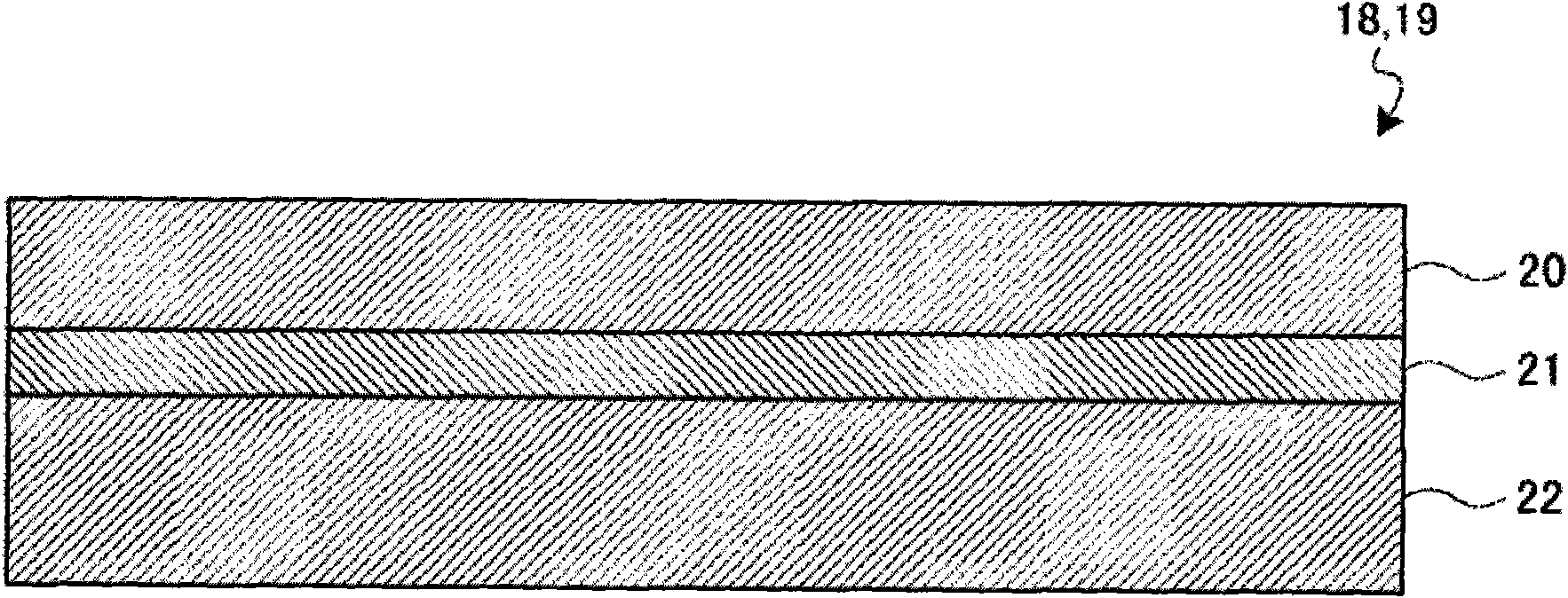

[0039] The inventors of the present application use the above-mentioned conductor 11, the first insulating material 12 and the second insulating material 13, the first non-woven fabric 14 and the second non-woven fabric 15, the first 1 ground foil 18 and second ground foil 19 and first shielding material 23 and second shielding material 24 as Figure 5 flex flat cable shown.

[0040] [Table 1]

[0041] [Table 2]

[0042] Specifically, according to the specifications shown in the above-mentioned Table 1, the flexible flat cable produced in the first embodiment uses a non-woven fabric having a flame retardant impregnated with cellulose as the first non-woven fabric 14 and the second non-woven fabric. Spinning15. In addition, according to the specifications shown in the above-mentioned Table 2, the configuration of the flexible flat cable manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com