Self-circulation type advanced hydraulic support

A hydraulic support and self-circulating technology, which is applied in mine roof support, mining equipment, earth drilling and mining, etc., can solve the problems of high labor intensity, laborious labor, and many manpower, so as to reduce labor intensity and increase support speed , the effect of improving the degree of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

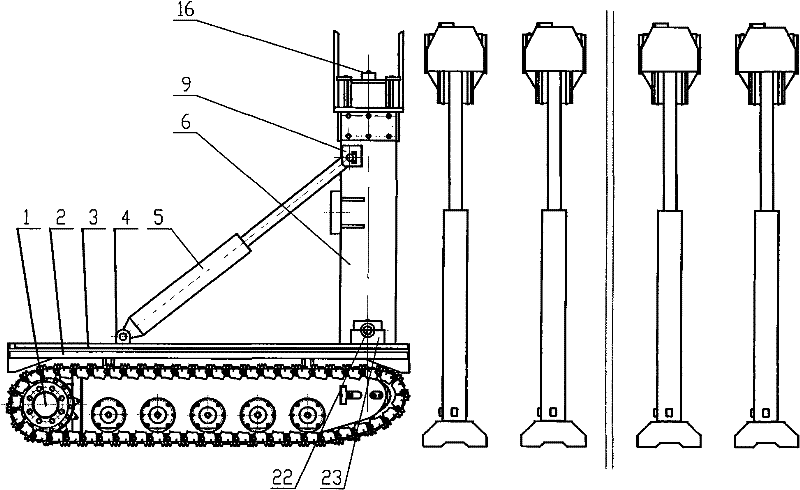

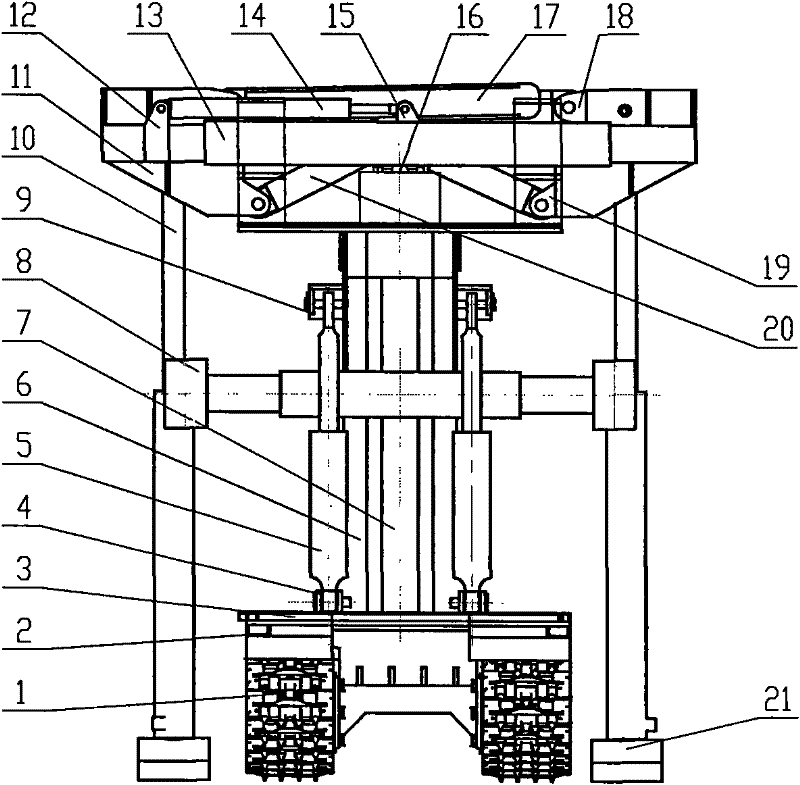

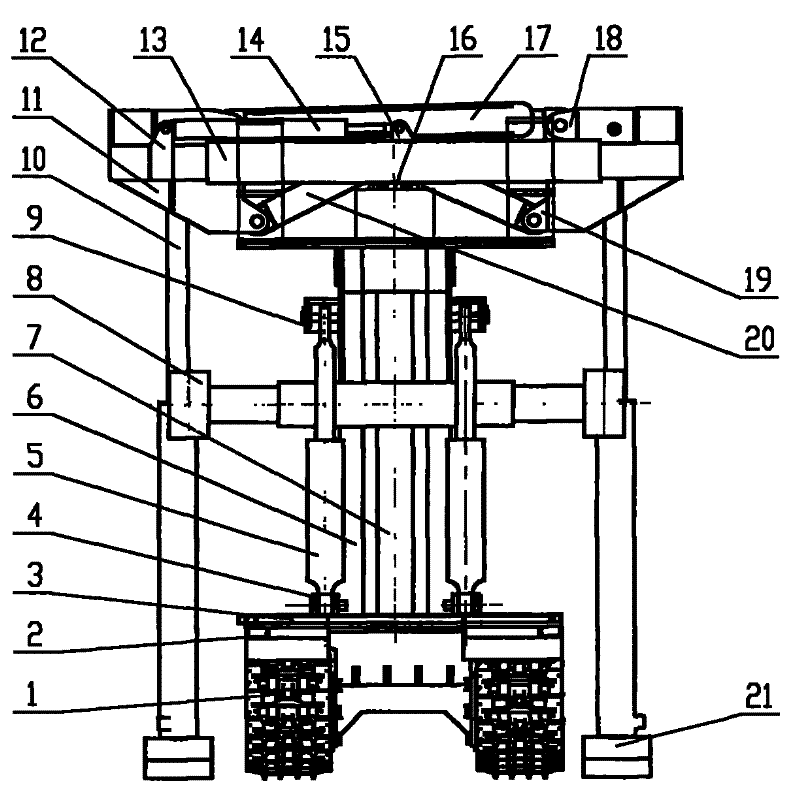

[0014] The present invention is composed of a walking part 1, a frame part, and a plurality of bracket parts. The frame part is composed of a lifting movable frame 16, a lifting swivel 6, an extended support head 8, a diagonal support cylinder 5, a lifting cylinder 7, and a small frame plate 3, the trolley frame plate 3 is installed on the support 2 of the walking part 1, the rotating shaft 22 on the lifting revolving frame 6 is installed and hinged on the support 23 of the trolley frame plate 3, and one end of the diagonal support cylinder 5 is connected to the trolley frame The lug 4 on the plate 3 is hinged, and the other end is connected with the lug 9 on the lifting turret 6. A lifting oil cylinder 7 is installed in the lifting turret 6, and the top of the lifting oil cylinder 7 is connected with the lug on the lifting frame 16, which lifts The bottom end of the oil cylinder 7 is hinged with the upper support of the lifting turret 6. An extension bracket 8 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com