Preparation method of polytetrafluoroethylene thread seal tape film for communication cable

A technology of polytetrafluoroethylene and communication cables, which is applied in the field of communication insulation materials, can solve the problems of large signal attenuation, large dielectric constant, and poor temperature resistance, and achieve reduced attenuation and loss, low dielectric constant, and good moisture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

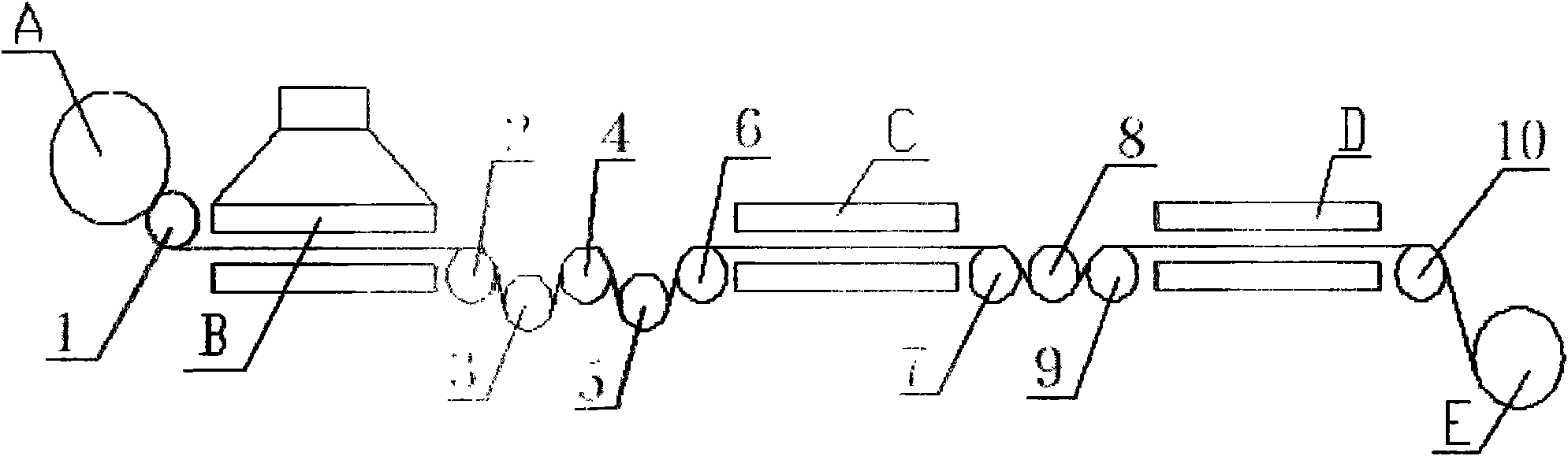

[0024] The method for manufacturing the polytetrafluoroethylene raw film for communication cables of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

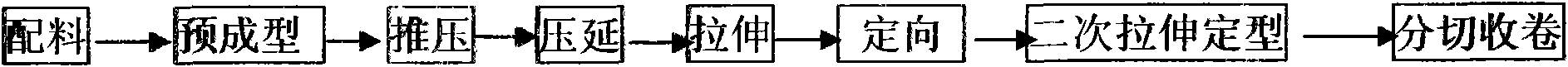

[0025] Method for manufacturing polytetrafluoroethylene raw material film for communication cables, such as figure 1 As shown, the production steps it includes are as follows:

[0026] 1. Ingredients and pretreatment:

[0027] (1) In view of polytetrafluoroethylene dispersion resin having multiple grades, the polytetrafluoroethylene dispersion resin of different grades has different molecular weight distributions and other characteristics, the present invention selects and uses molecular weight at 300-500 ten thousand by screening, particle diameter is 480-520um, standard relative density is 2.15-2.18, water content ≤ 0.03%, tensile strength ≥ 34Mpa, elongation at break ≥ 400% polytetrafluoroethylene dispersion resin; the function of the polytetrafluoroethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com