Preparation method of wind sand solidification paver brick

A technology for pavement bricks and sandstorms, applied in chemical instruments and methods, clay preparation devices, manufacturing tools, etc., to achieve the effects of wide application, good freeze resistance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

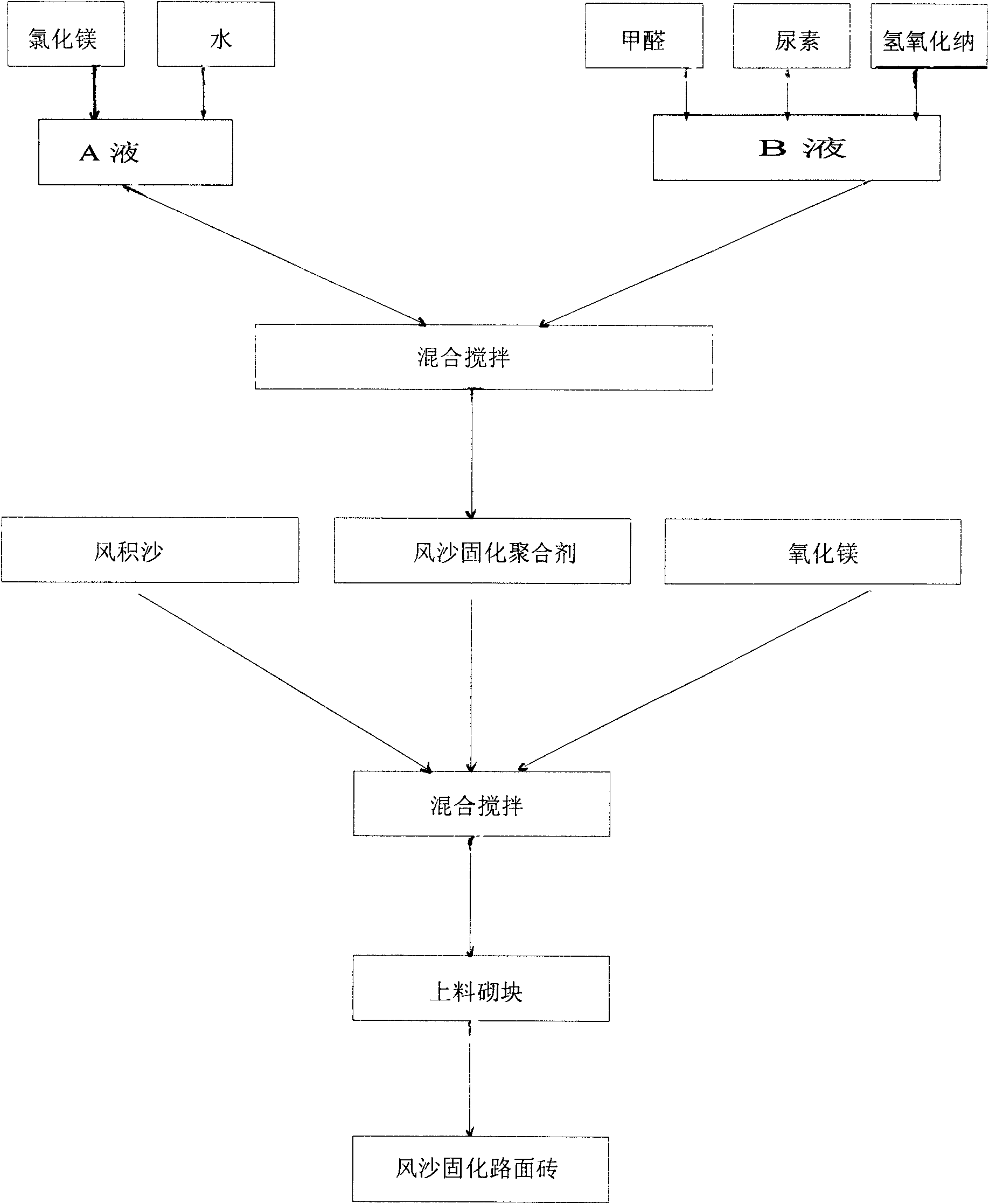

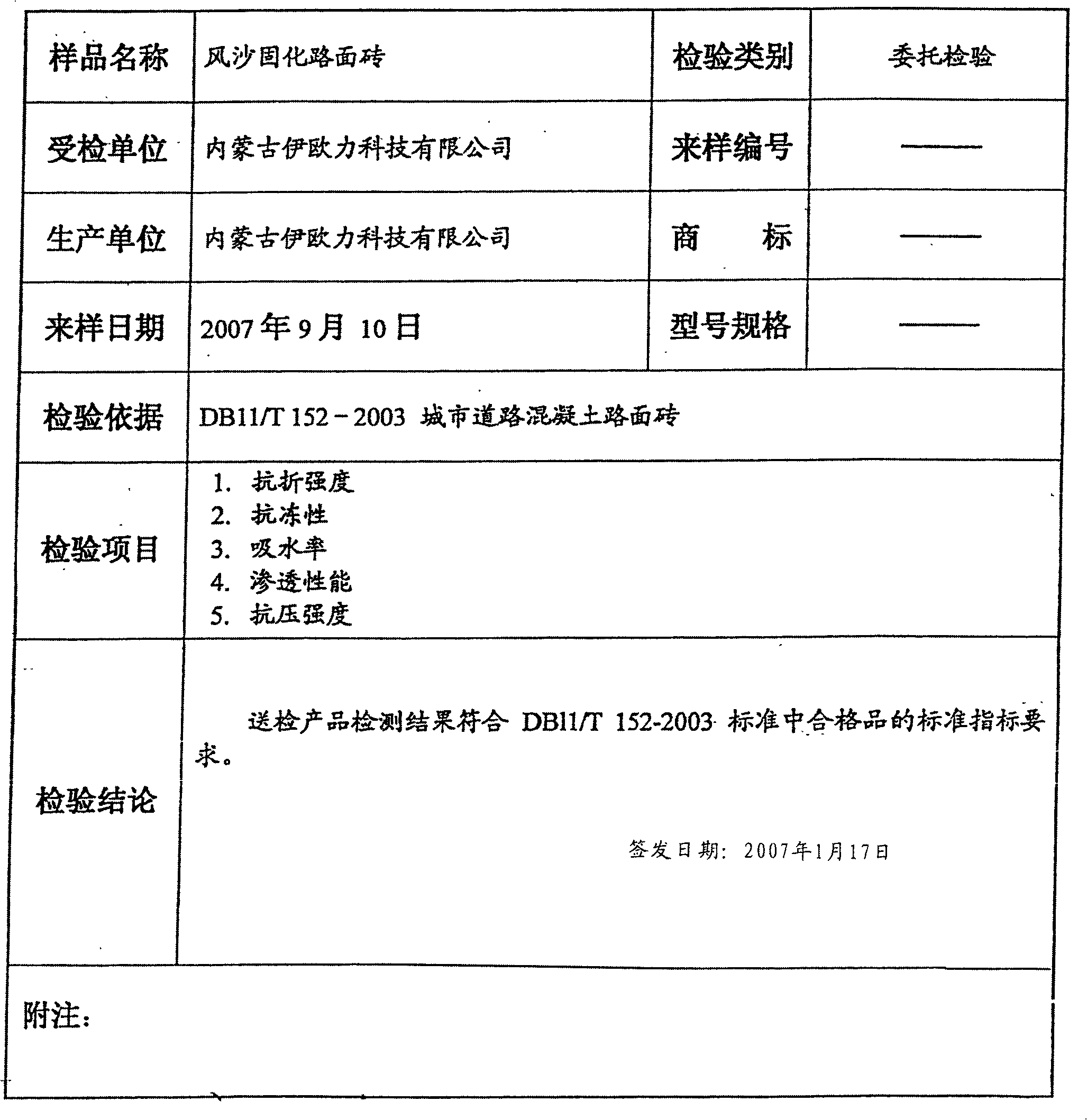

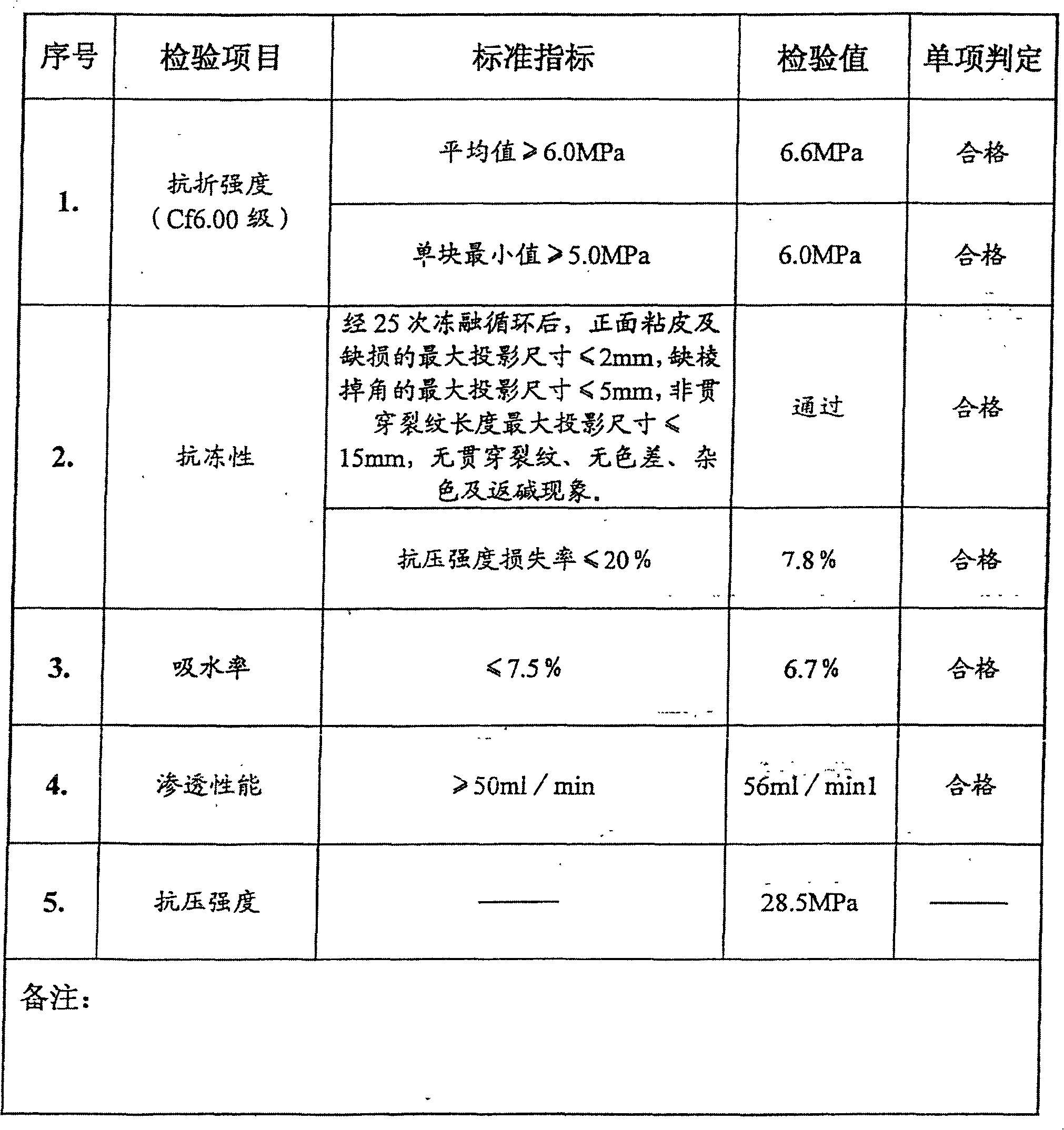

[0011] Examples are given below: in order to prepare 250 kilograms of wind-blown sand curing polymerization agent finished products. Such as figure 1 As shown, under normal temperature and pressure, dissolve 60 kg of magnesium chloride with 125 kg of water to make liquid A; fully mix 2.5 kg of formaldehyde, 60 kg of urea, and 1 kg of sodium hydroxide to make liquid B; age 5 hours. Put the two solutions of A and B into a miscible, mix them and then fully stir them to obtain the wind-sand solidification polymerization agent. When in use, mix 250 kg of this wind-blown sand solidifying polymer with 3,000 kg of wind-blown sand and 350 kg of magnesium oxide, then add a certain amount of glass fiber filaments (other fiber filaments are also available), and use a 350-type mixer to stir evenly. Then use the HXQT4WS-20 block forming machine to load the blocks, vibrate, compact and finally form them. The compressive strength is 28.5MPa, the flexural strength is 6.6MPa, the compressive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com