Ice melting method for overhead contact system of electrified railway and ice melting system thereof

A technology of electrified railway and ice-melting method, which is applied in the direction of electrical components, cable installation, overhead line/cable equipment, etc., can solve the problem of not being able to melt the additional wire ice coating, and achieve the effect of eliminating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

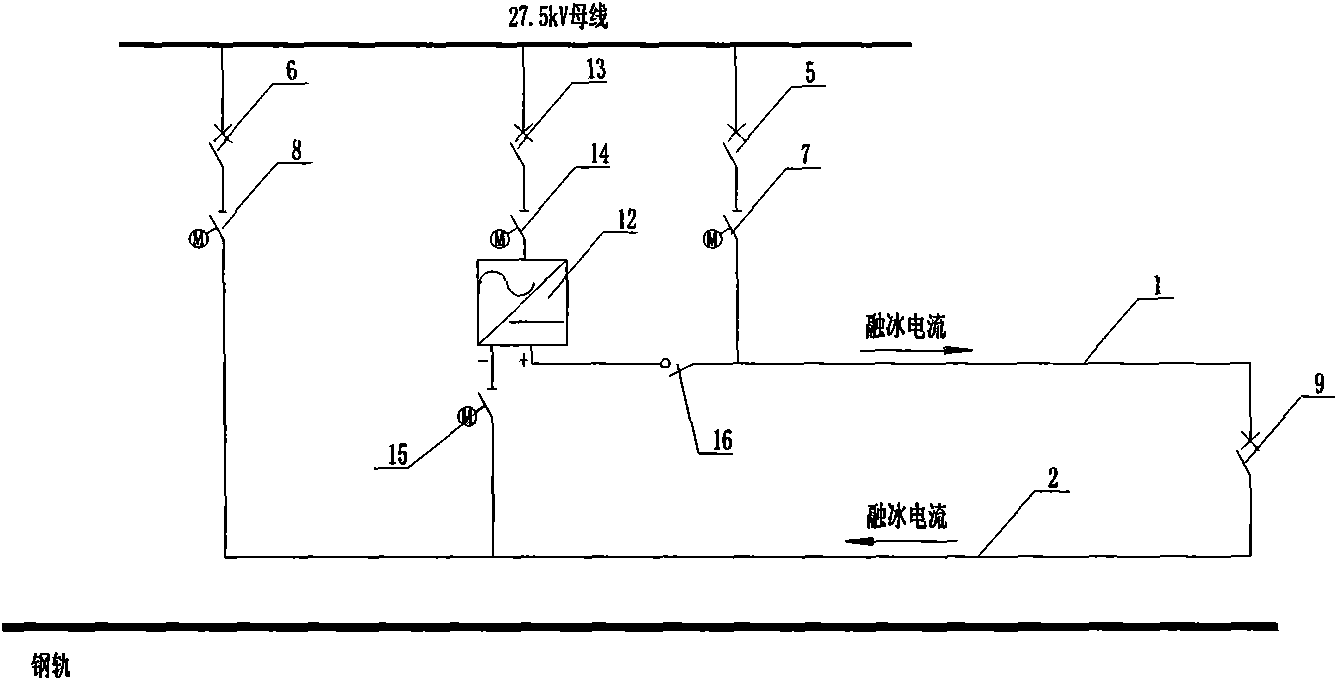

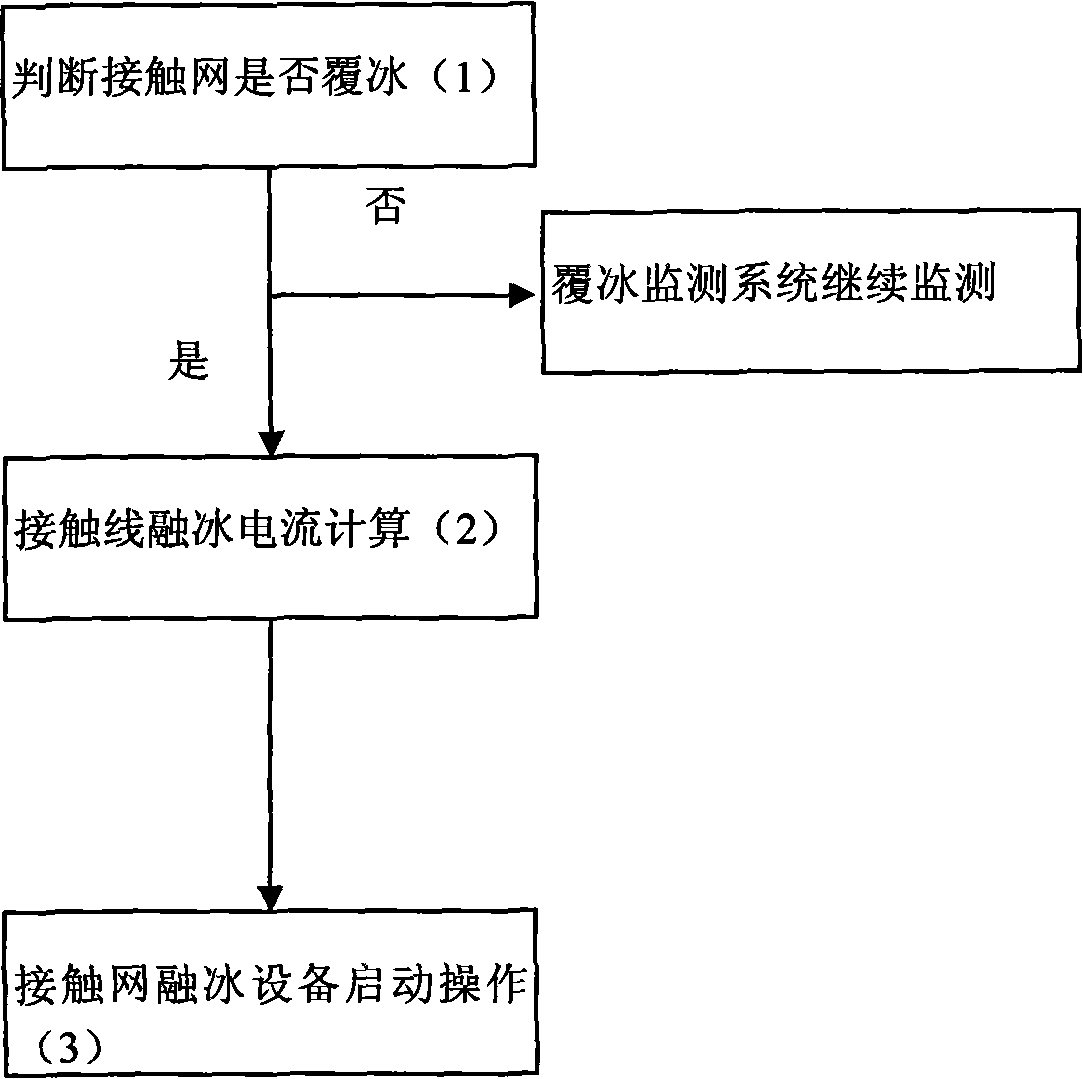

[0039] see figure 1 , the present invention includes ice melting data processing and control module, bipolar load isolating switch 4, AC ice melting current limiting device 3, AC ice melting current limiting device 3 includes ice melting resistance box, ice melting capacitor box, air cooling or water cooling device , Control protection device, ice-melting resistance box is used to adjust the ice-melting current value, adopts sealed type.

[0040] The AC current-limiting device 3 for melting ice is installed in the partition station, the downlink catenary 2 is connected to the integrated grounding box 10, and a grounding isolation switch 11 is arranged between them, and the uplink and downlink catenary 1 and 2 pass through the bipolar load of the partition station at the end of the power supply arm The isolating switch 4 is connected in serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com