Pulse full-fiber laser

A laser, all-fiber technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of high-energy pulsed laser output, complex structure, and narrow output pulse width, which are difficult to double-clad fibers, and achieve High peak power, good beam quality and adjustable repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings.

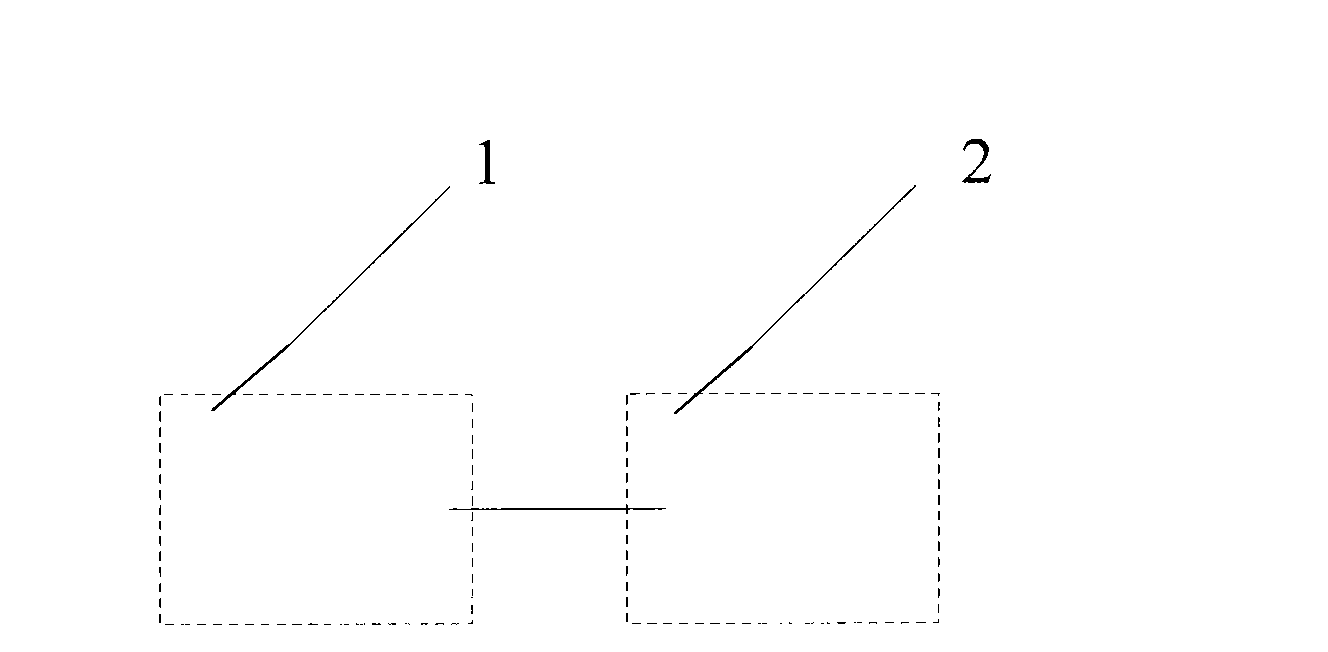

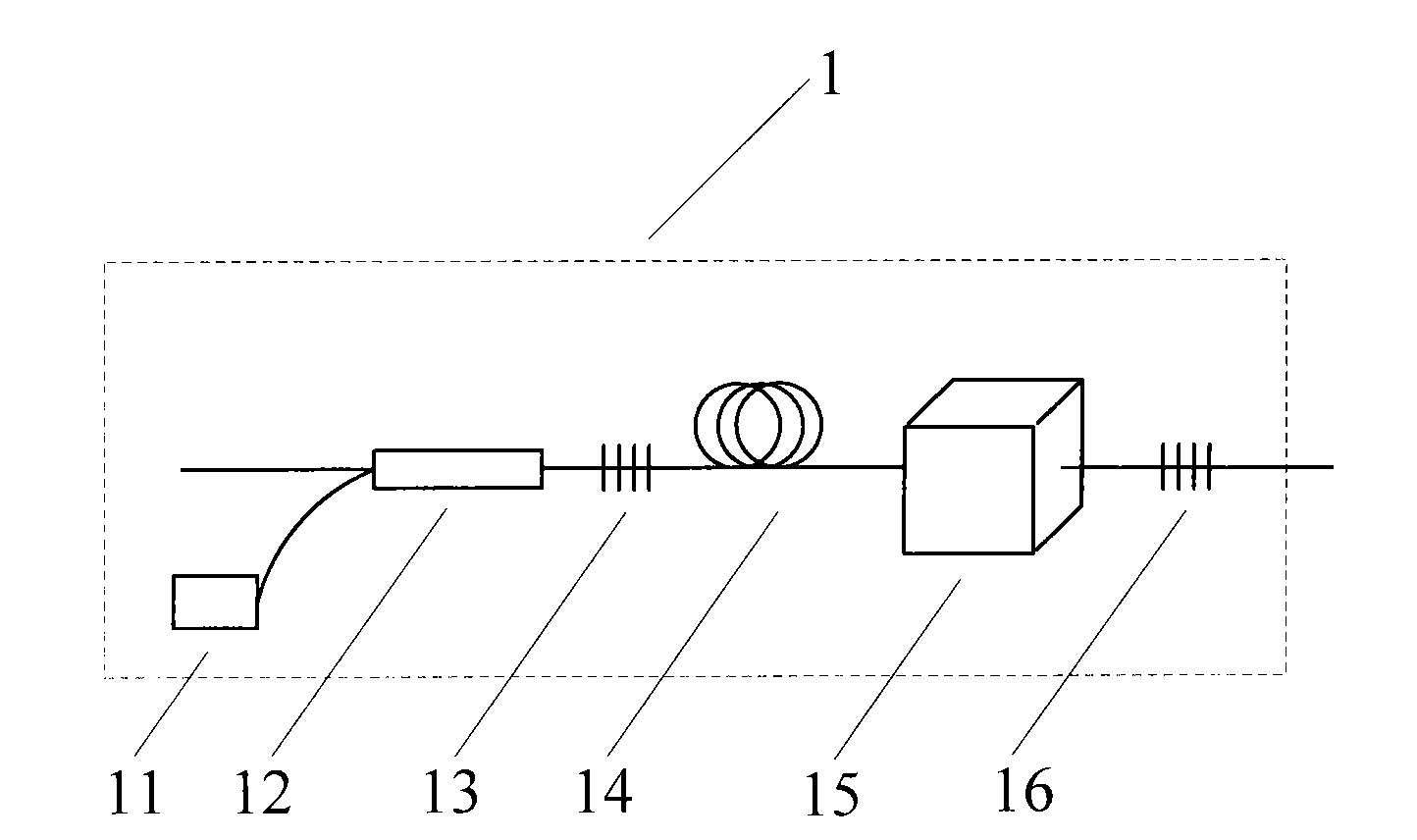

[0027] Such as figure 1As shown, it consists of two parts, the main oscillator 1 and the power amplifier 2, wherein the main oscillator 1 consists of a semiconductor pump source 11 with a pigtail, a (1+1)×1 side coupler 12, and a signal light reflection fiber grating 13 , double-clad ytterbium-doped fiber 14, a fiber-coupled acousto-optic modulator 15, and an output-coupled fiber grating 16. The structure of the main oscillator 1 is as follows figure 2 As shown, the pump input fiber in the (1+1)×1 side coupler is connected to the semiconductor pump source with pigtails, and the output end of the output fiber and the signal light reflection fiber grating signal light reflection fiber grating 13 passes through the double-clad layer The ytterbium-doped optical fiber 14 is connected to the fiber-coupled acousto-optic modulator 15, and the output end of the fiber-coupled acoust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com