Absorption solvent used for catching or separating carbon dioxide

A technology for absorbing solvents and carbon dioxide, which is applied in the direction of absorption, separation methods, and dispersed particle separation, can solve the problems of high cost of use and high degradation, and achieve the effects of low heat of reaction, high solubility, and reduced degradation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

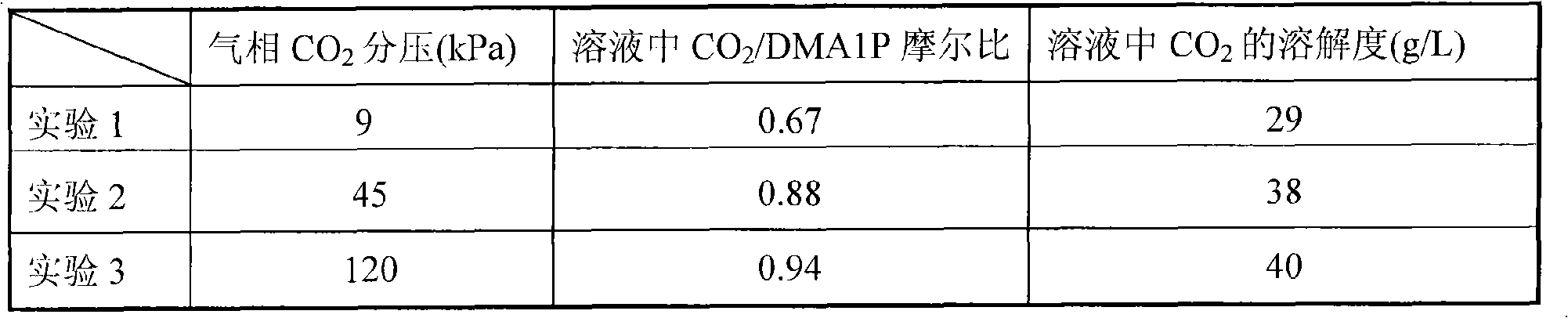

[0013] Get three parts of 3-dimethylamino-1-propanol aqueous solution, wherein, the content of 3-dimethylamino-1-propanol is

[0014] 10wt%, the rest is composed of monoethanolamine, dimethyl sulfoxide, K 2 CO 3 , corrosion inhibitor and water solvent. Set the temperature at 40 °C, gaseous CO 2 Partial pressure of 9kPa, 45kPa, 120kPa containing CO 2 and N 2 The mixed gas of the mixed gas is input into three parts of the solvent respectively, and after the gas-liquid two-phase reaches equilibrium, the CO in the solvent is absorbed 2 and 3-dimethylamino-1-propanol (DMA1P) molar ratio and CO in the absorption solvent 2 See Table 1 for the solubility.

[0015] Table 140°C, 10wt% 3-dimethylamino-1-propanol aqueous solution experimental results

[0016]

Embodiment 2

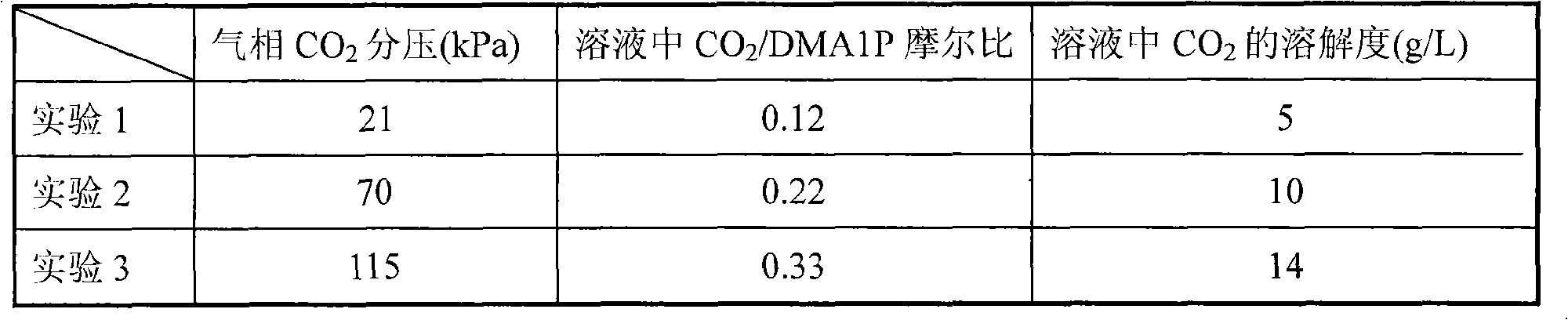

[0018] Get three parts of 3-dimethylamino-1-propanol aqueous solution, wherein, the content of 3-dimethylamino-1-propanol is 10wt%, all the other are composed of monoethanolamine, dimethylsulfoxide, Na 2 CO 3 , corrosion inhibitor and water solvent. Set the temperature at 120°C, gaseous CO 2 Partial pressure of 21kPa, 70kPa, 115kPa containing CO 2 and N 2 The mixed gas of the mixed gas is input into three parts of the solvent respectively, and after the gas-liquid two-phase reaches equilibrium, the CO in the solvent is absorbed 2 and 3-dimethylamino-1-propanol (DMA1P) molar ratio and CO in the absorption solvent 2 See Table 2 for the solubility.

[0019] Table 2120°C, 10wt% 3-dimethylamino-1-propanol aqueous solution experimental results

[0020]

Embodiment 3

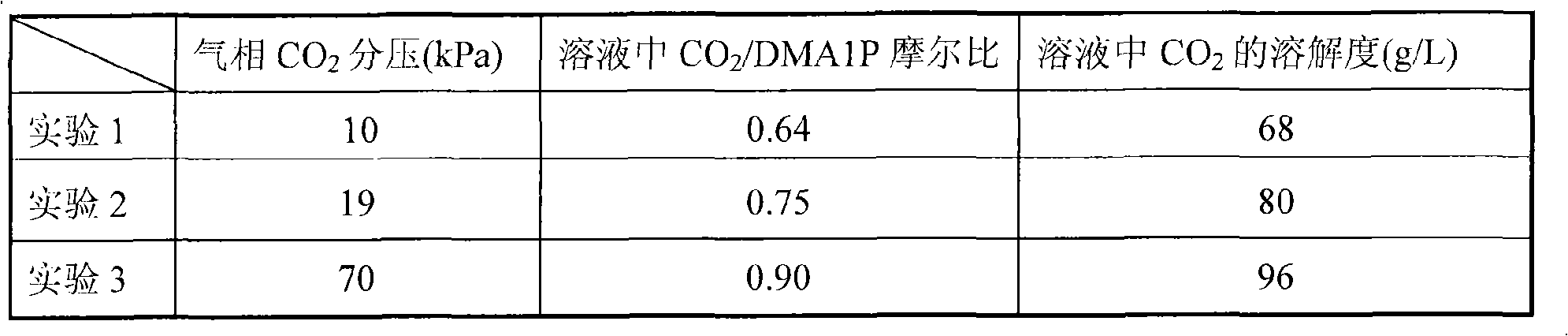

[0022] Get three parts of 3-dimethylamino-1-propanol aqueous solution, wherein, the content of 3-dimethylamino-1-propanol is 25wt%, all the other are made of n-propanolamine, sulfolane, K 2 CO 3 , corrosion inhibitor and water solvent. Set the temperature at 40 °C, gaseous CO 2 Partial pressure of 10kPa, 19kPa, 70kPa containing CO 2 and N 2 The mixed gas of the mixed gas is input into three parts of the solvent respectively, and after the gas-liquid two-phase reaches equilibrium, the CO in the solvent is absorbed 2 and 3-dimethylamino-1-propanol (DMA1P) molar ratio and CO in the absorption solvent 2 See Table 3 for the solubility.

[0023] Table 340 ℃, 25wt% 3-dimethylamino-1-propanol aqueous solution experimental results

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com