Method and equipment for culturing seawater pearl shell

A breeding method and pearl technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as low product value, inability to resist wind and waves, and easy deposition of sediment, so as to improve market competitiveness and survival rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

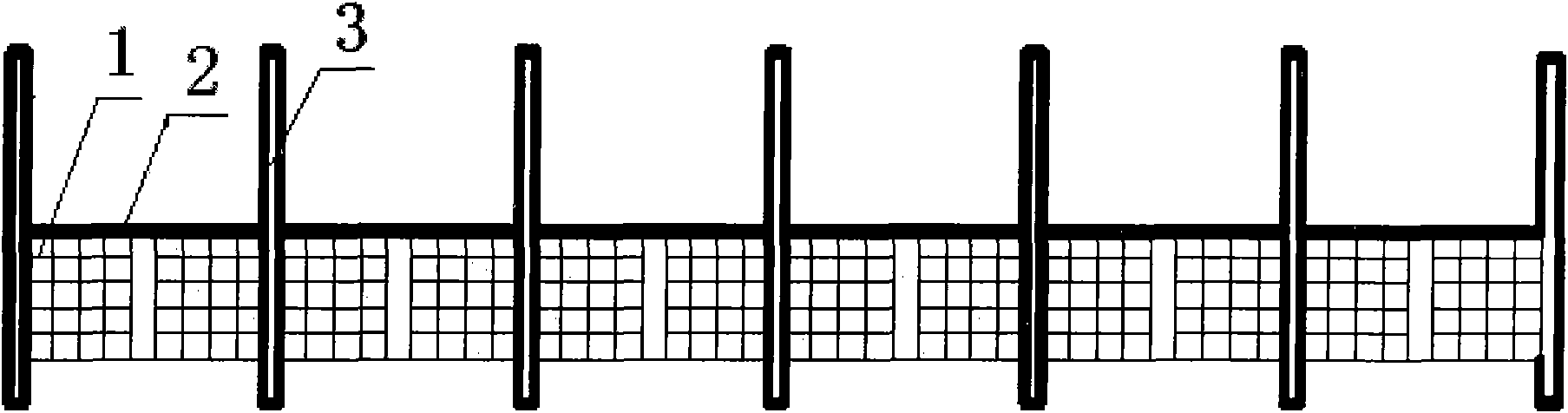

[0021] Such as figure 1 As shown, after pearl oysters are placed inside the cage box body 1, several (more than five, generally about fifteen) box bodies 1 are connected in series with ropes 2 and then tied to fixed pillars 3 (wooden pillars, metal rods, aluminum poles, etc.) alloy or stainless steel rod), the cage box body 1 and the seabed keep more than 50 cm-1 meter, to avoid silt from falling into the cage box body 1.

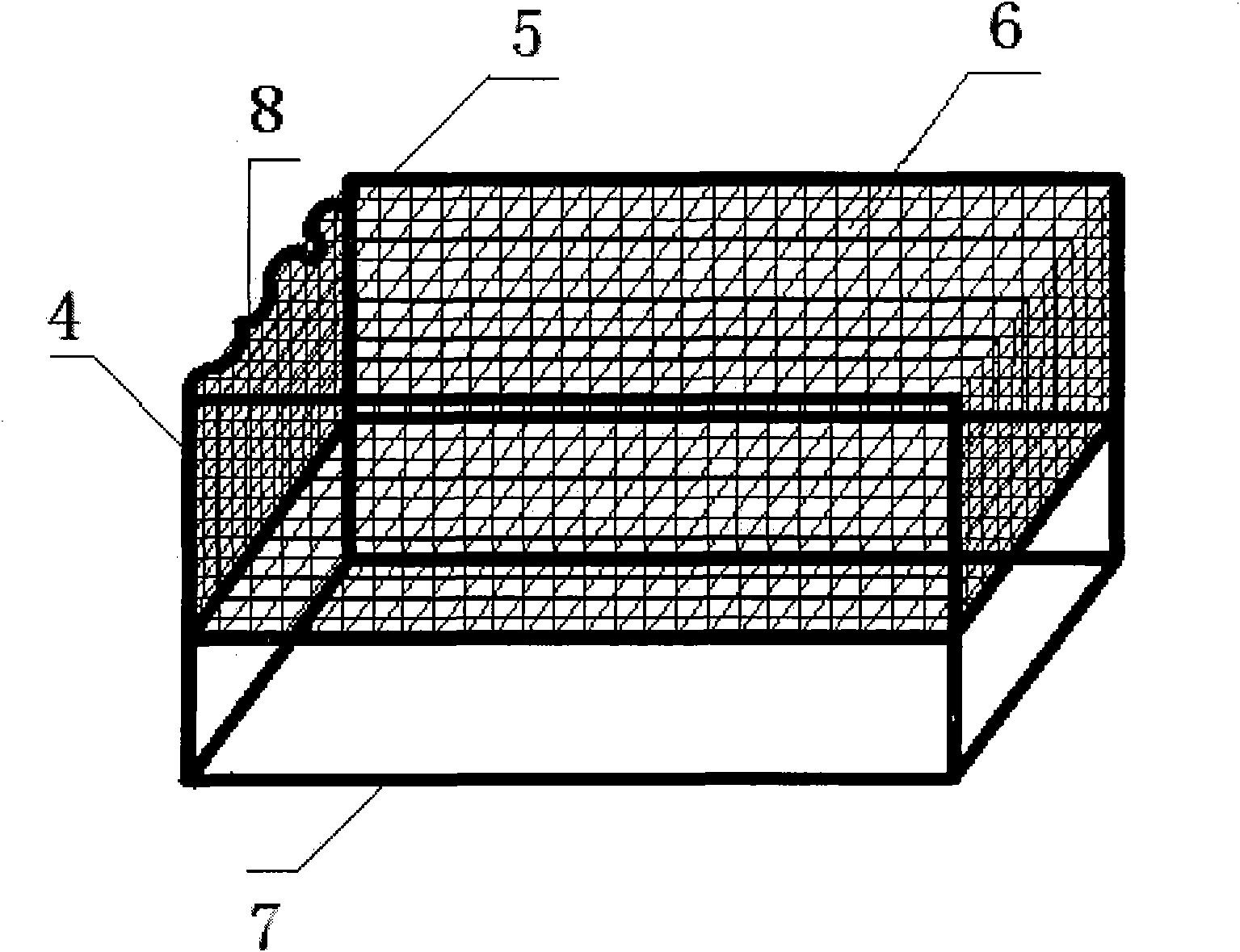

[0022] Such as figure 2 As shown, the box body 1 adopts a multi-layer structure with an opening 8 on the top, and each layer is provided with a horizontal support bar 5 and a vertical support bar 4, and the horizontal support bar 5 and the vertical support bar 4 are connected with the grid plate 6 around the box body. 1. Pearl oysters are placed inside, and a gridless base 7 is provided below the box body. The horizontal support bar 5, the vertical support bar 4 and the base 7 are made of metal strips, and the metal strips are wrapped with plastic tubes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com