Floating hydraulic generator

A hydro-generator and pulley technology, which is applied in hydropower stations, engine components, machines/engines, etc., can solve the problems of low utilization rate of hydrodynamic energy resources, loss of hydrodynamic energy, and unfavorable navigation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

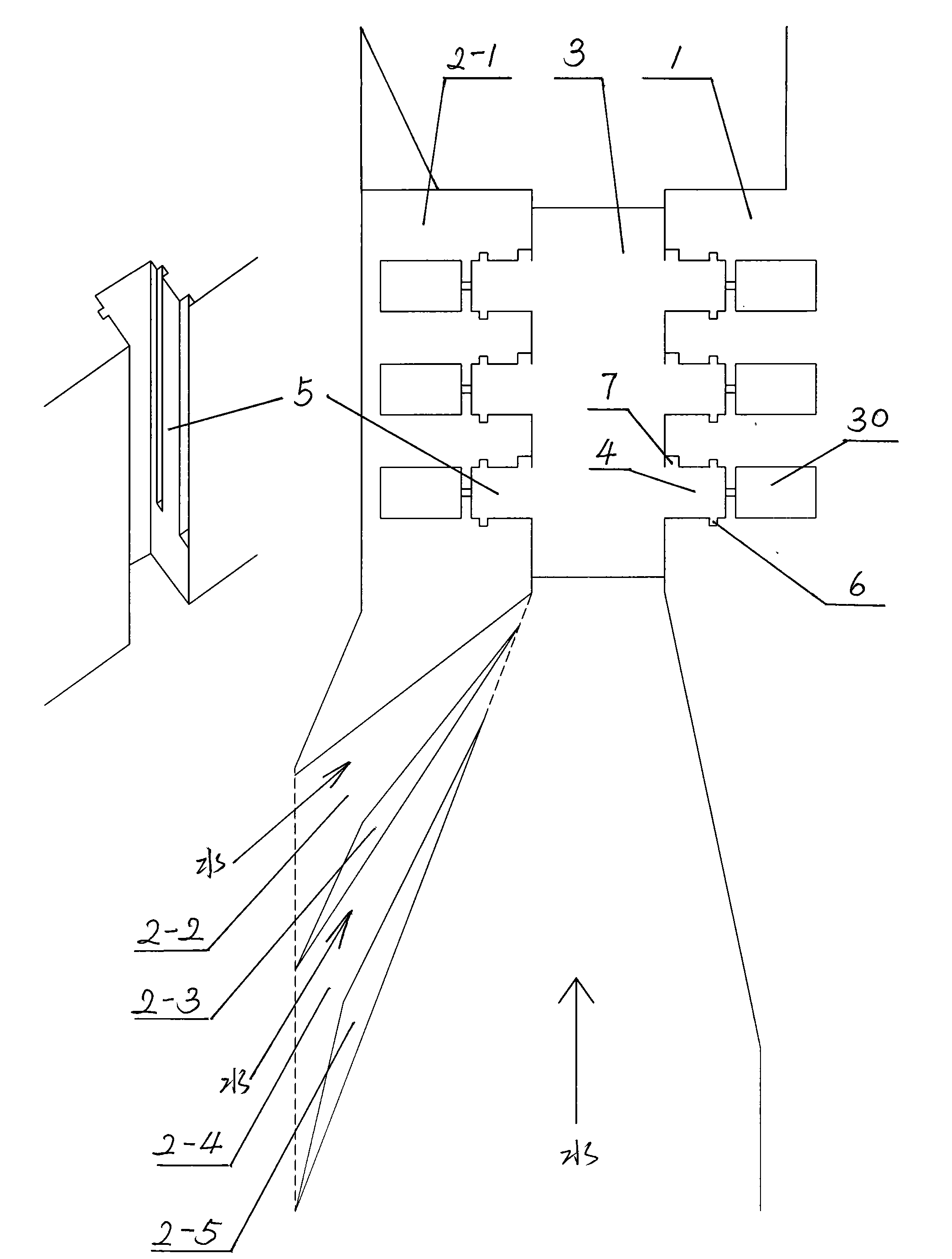

[0032] Such as figure 1 , Build reinforced concrete lathe in river: build main frame 1 on one bank of river, also can build main frame in the river channel of offshore as river course width is big. Separate sub-frames 2-1, 2-3, and 2-5 are built in a certain span horizontally with the main frame in the river channel; they can be arranged continuously depending on the flow conditions and needs. The main frame and the auxiliary frame form a water flow channel in the machine tool that is wide upstream, narrow downstream, and finally gradually wider. Water replenishment channels 2-2, 2-4 are arranged alternately with auxiliary machine bases 2-1, 2-3, and 2-5; if the main base is also built in an offshore river instead of leaning against a certain bank, then its The configuration stands opposite to the sub-frame and is congruent (figure omitted). The water inlet of the supplementary channel is wide, upstream of the river water flow direction, and the water outlet is narrow, downs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com