Odor type jacquard decorative fabric and manufacturing method thereof

A technology for decorative fabrics and jacquards, which is applied in the field of jacquard scented decorative fabrics and its production. It can solve the problems of limited fragrance holding and release time, affecting the appearance of jacquard, and short fragrance holding time, and achieves pleasant fragrance and high adsorption. The effect of force and processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

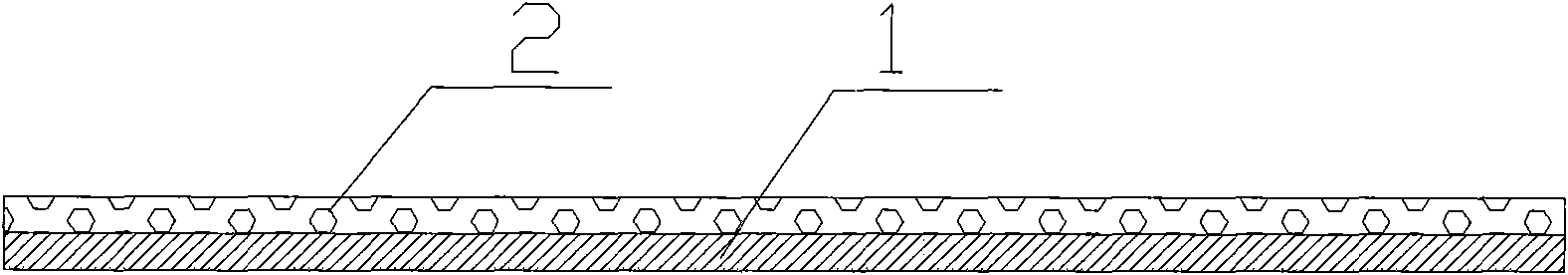

Image

Examples

Embodiment 1

[0011] Embodiment 1: Chitosan essence microcapsule slurry (formulation weight): 10-30 parts of chitosan essence microcapsules; 10-50 parts of cationic core-shell adhesive; the remainder is water. The formula of the chitosan essence microcapsules is: 15-50 parts of chitosan; 5-10 parts of glacial acetic acid; 10-15 parts of glucoside; 30-50 parts of essential oil; 5-10 parts of PVPK30. The cationic core-shell polymer binder contains a cationic emulsifier.

Embodiment 2

[0012] Embodiment 2: On the basis of embodiment 1, 10 parts of chitosan essence microcapsules; 10 parts of cationic core-shell binder; remainder is water. The formula of the chitosan essence microcapsules is: 15 parts of chitosan; 5 parts of glacial acetic acid; 10 parts of glucoside; 30 parts of essential oil; 5 parts of PVPK30. The cationic core-shell polymer binder contains a cationic emulsifier.

Embodiment 3

[0013] Embodiment 3: On the basis of embodiment 1, 30 parts of chitosan essence microcapsules; 50 parts of cationic core-shell binders; remainder is water. The formula of the chitosan essence microcapsules is as follows: 50 parts of chitosan; 10 parts of glacial acetic acid; 15 parts of glucoside; 50 parts of essential oil; 10 parts of PVPK30. The cationic core-shell polymer binder contains a cationic emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com