Planetary gear type selvage machine of loom

A technology of planetary gears and edge looms, which is applied to gear transmissions, looms, transmissions, etc., can solve problems such as accelerated gear tooth surface wear, planetary edge loom device impact, bobbin frame damage, etc., to prevent bobbin The frequent damage of the frame and the effect of preventing the accelerated wear of the gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

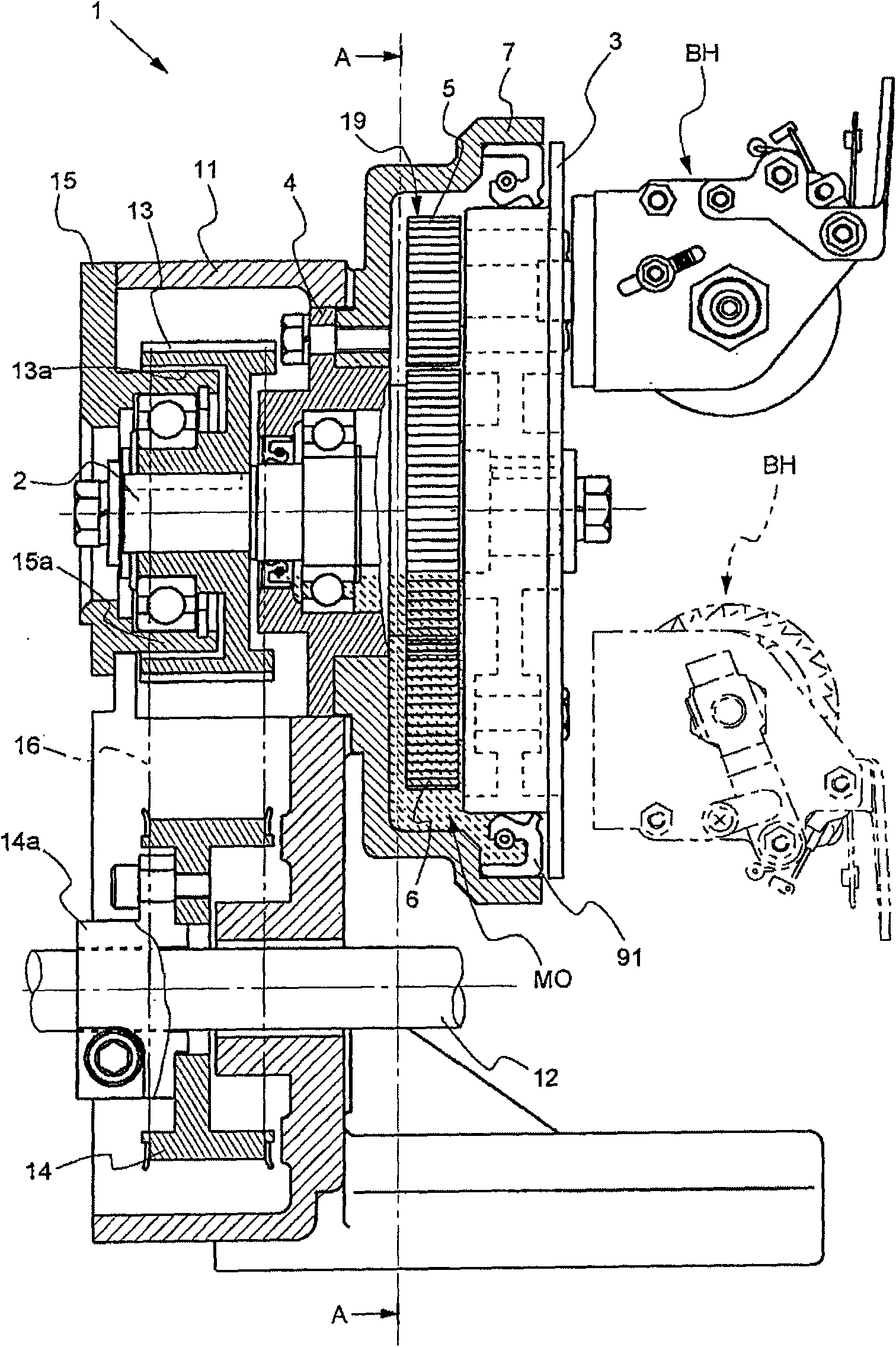

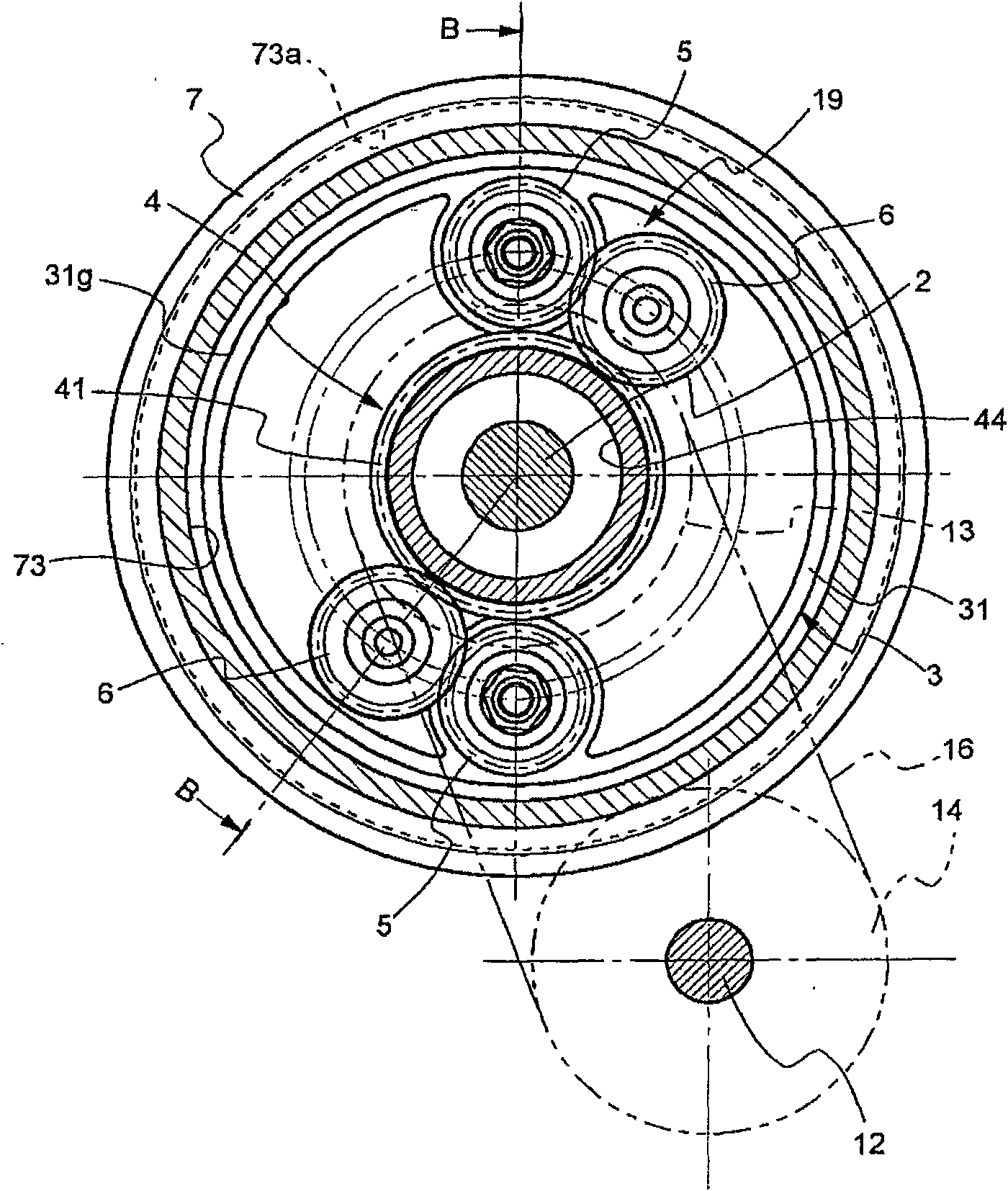

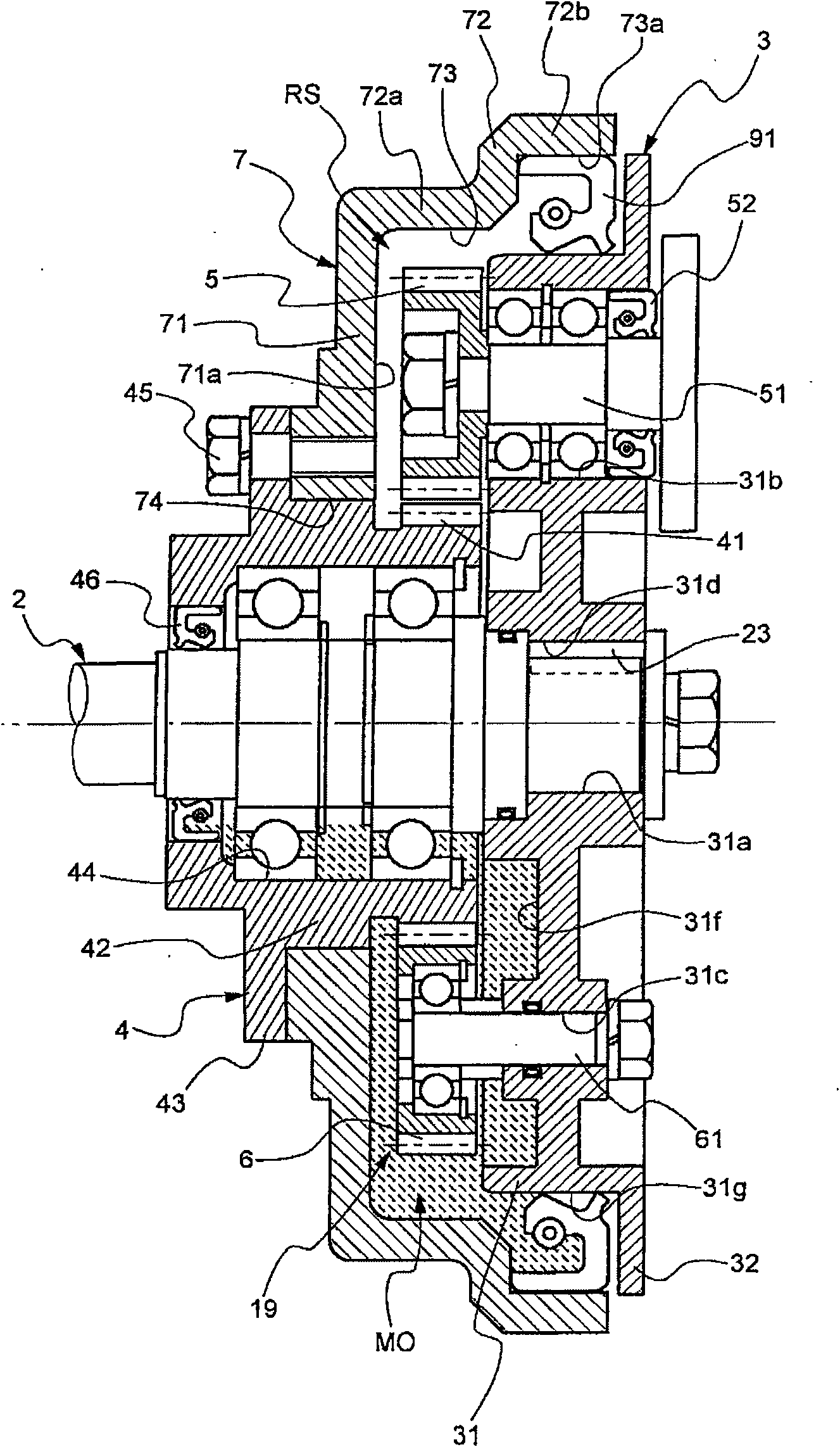

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0025] Figure 1-Figure 3 Shown is one embodiment of the invention, figure 1 It is a partial side sectional view showing one embodiment of the planetary selvedge device to which the present invention is applied, figure 2 It is the rear view of the planetary gear mechanism part of the planetary edge selvage machine. in addition, image 3 yes figure 1 An enlarged cross-sectional view of the peripheral portion of the planetary gear mechanism, which is an important part of the present invention, of the planetary edge selvage machine. also, figure 1 , image 3 Part of the planetary gear mechanism is shown as seen in the direction of the arrow figure 2 The section along the line B-B of figure 2 Indicated as seen in the direction of the arrow figure 1 A cross-sectional view along the line A-A. but, figure 2 Pulleys and the like which are not originally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com