Magnetic information medium recording/reproducing device

A media recording and reproducing device technology, applied in the direction of recording information storage, recording carrier guidance, instruments, etc., can solve the problems of unstable output, difficult transmission, increased inertia, etc., and achieve stable writing/reading output, Effect of low power consumption and reduction of inertial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

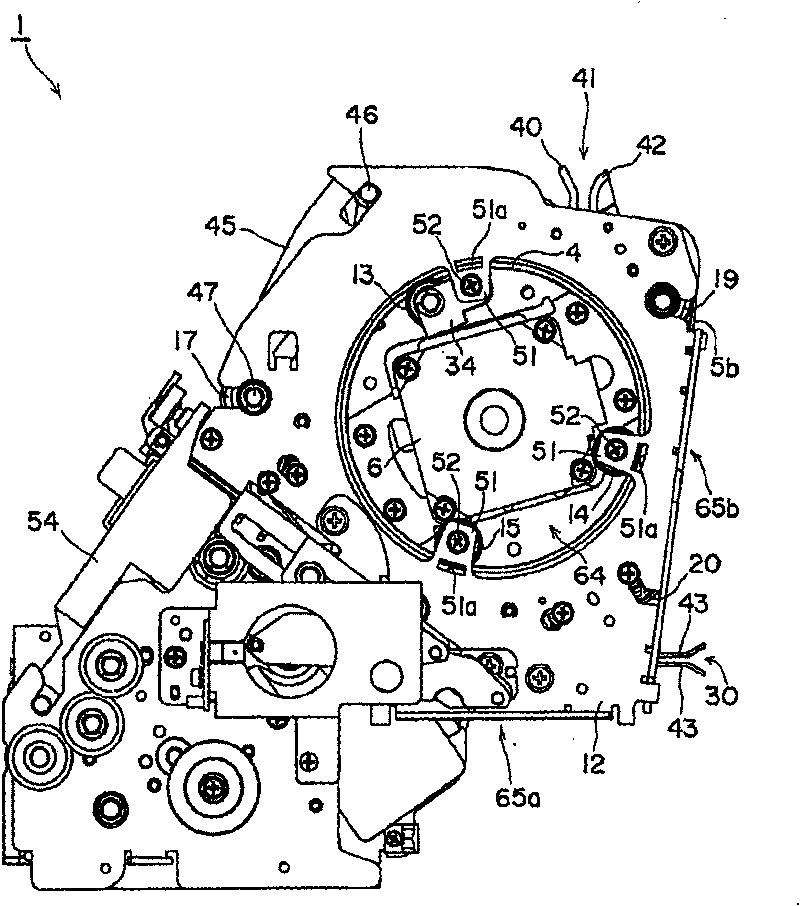

[0049] Hereinafter, the configuration of the present invention will be described in detail based on an example of the embodiment shown in the drawings.

[0050] Figure 1 to Figure 8 An embodiment of the present invention is shown. The magnetic information medium recording and reproducing apparatus 1 of the present invention comprises: the magnetic drum 4 that rotates freely, the conveying mechanism 5 that conveys magnetic information medium along the outer periphery of magnetic drum 4, drives the driving part 6 of this conveying mechanism 5, carries out the reading of magnetic information. Or write head 7. The tilting of the drum 4 and the magnetic head 7 is such that the distance between the drum 4 and the transport mechanism 5 near the magnetic head 7 is widened or the pressure therebetween is reduced.

[0051] The magnetic information medium recording and reproducing device is equipped with a conveying mechanism 5 composed of a flat belt around the magnetic drum 4, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com