Cup-mouth copying rotary welding machine

A cup mouth and welding machine technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of uneven surface of the cup mouth, affecting the appearance of products, etc., and achieve the effect of smooth surface of the cup mouth and good welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Different from the ordinary welding machine in the prior art, the cup mouth profiling spin welding machine of the present invention can automatically adjust its relative position to the cup mouth according to the surface condition of the cup mouth during the welding process, so as to achieve a good The cooperation ensures the welding quality and the smoothness of the cup surface after welding.

[0022] Below in conjunction with specific embodiment the present invention is described in further detail:

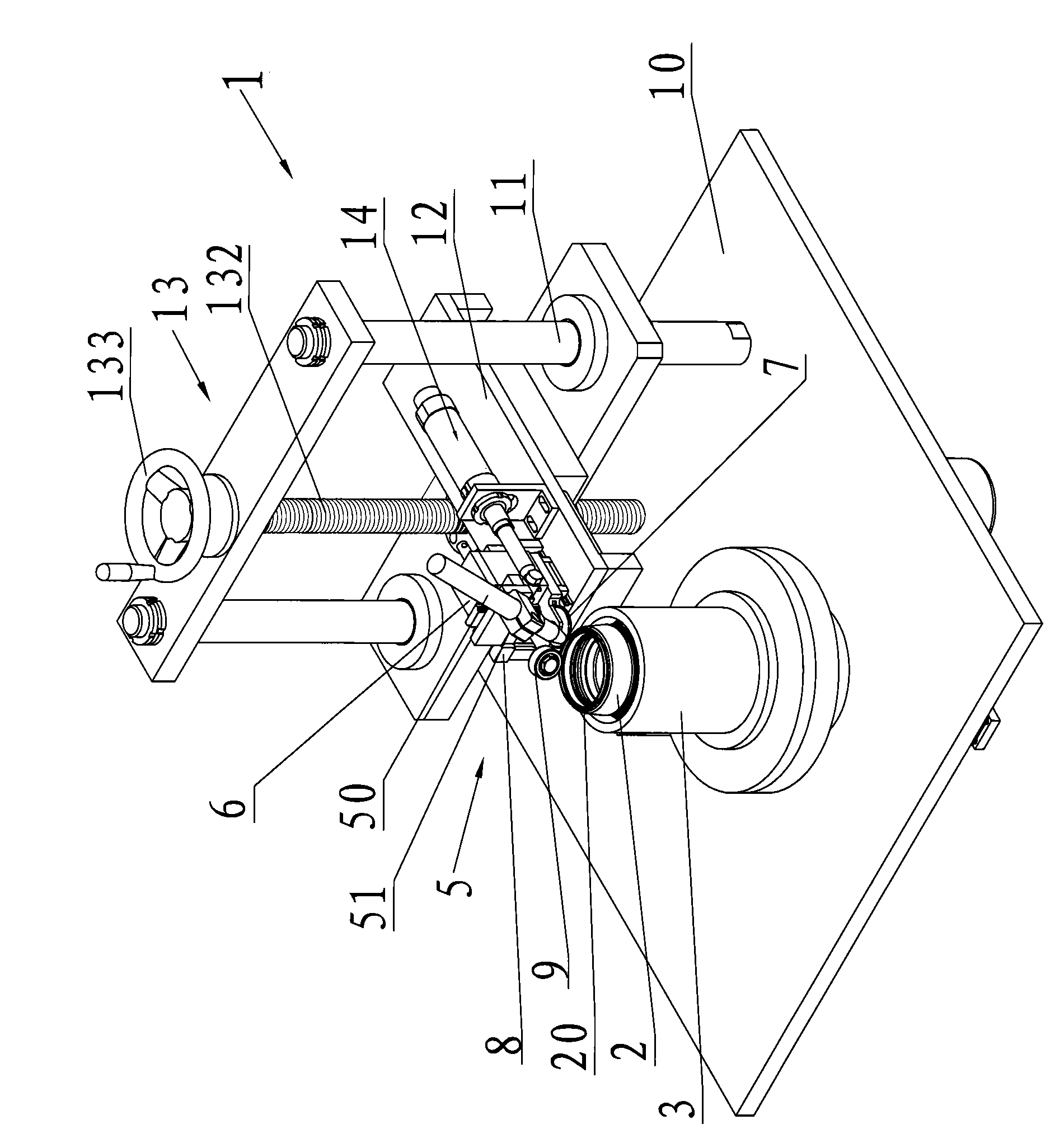

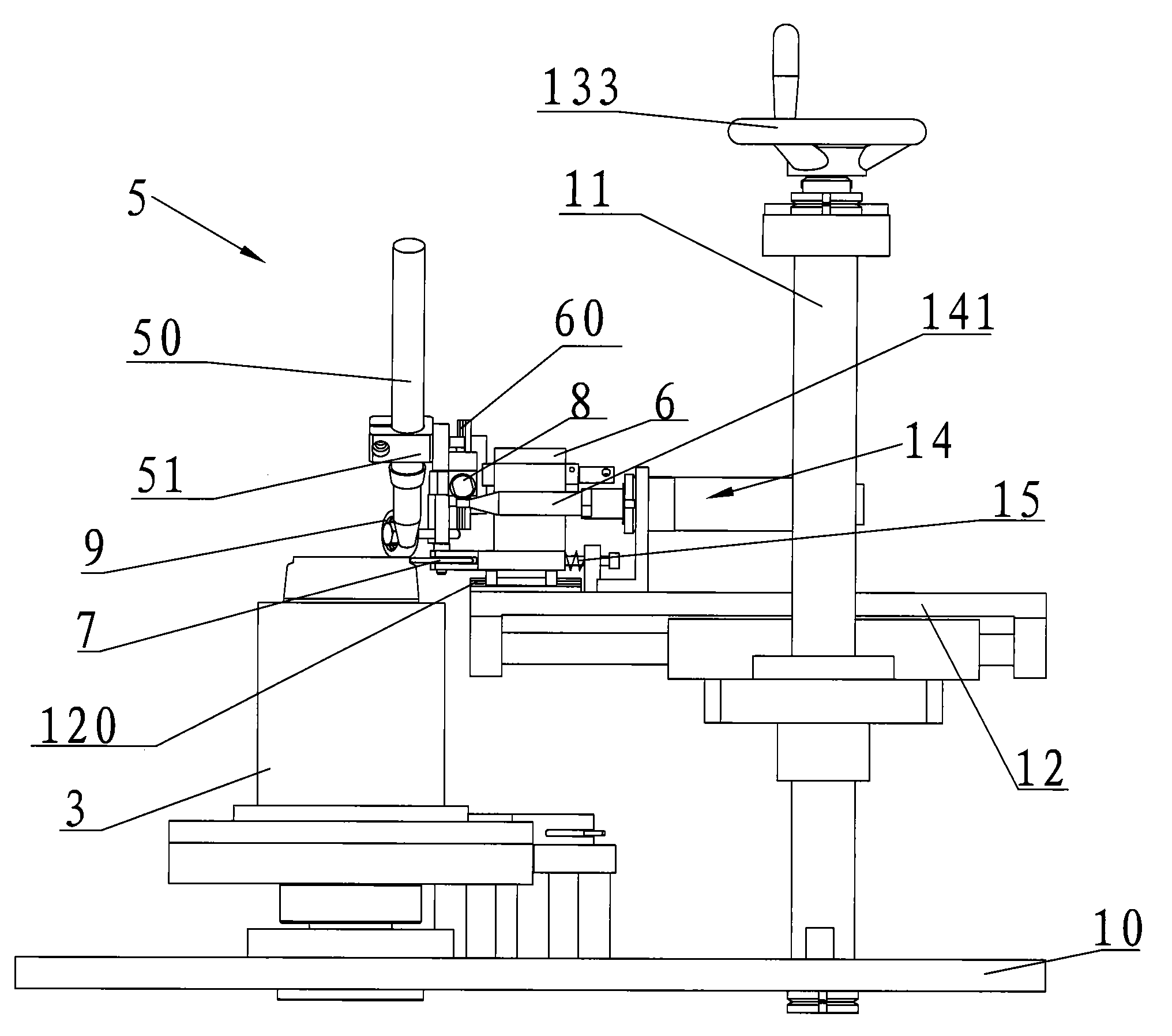

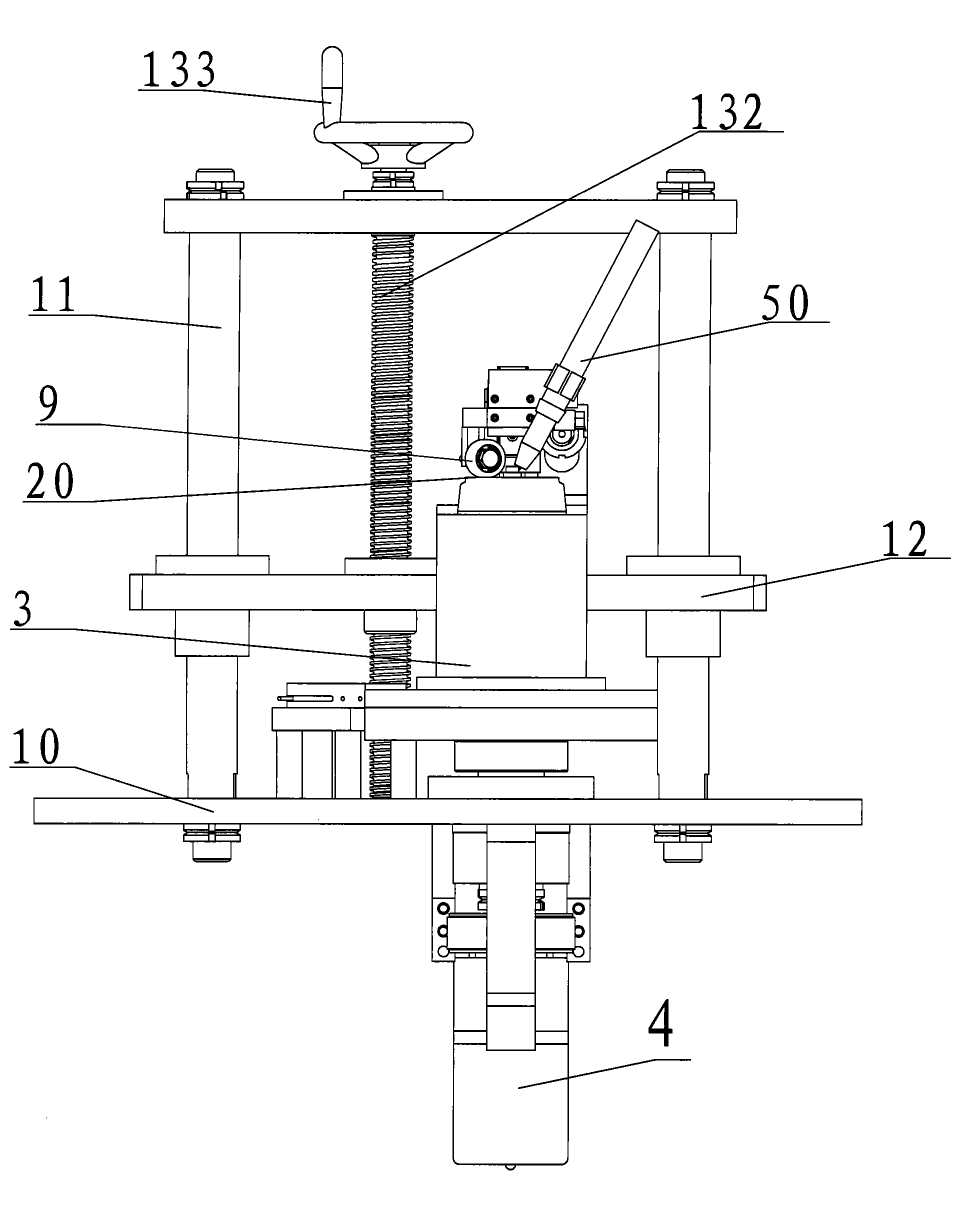

[0023] Such as Figure 1 to Figure 4 As shown, according to the cup rim profiling spin welding machine of the present embodiment comprises:

[0024] Frame 1, which includes a base 10, a pair of guide posts 11 fixedly arranged on the base 10 parallel to each other, and a workbench 12 supported by the pair of guide posts 11;

[0025] The rotating fixed mold 3 is a barrel-shaped structure, which is rotatably arranged on the base 10, and the cup 2 to be processed is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com