Visible light response catalyst and preparation and application thereof

A catalyst and visible light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

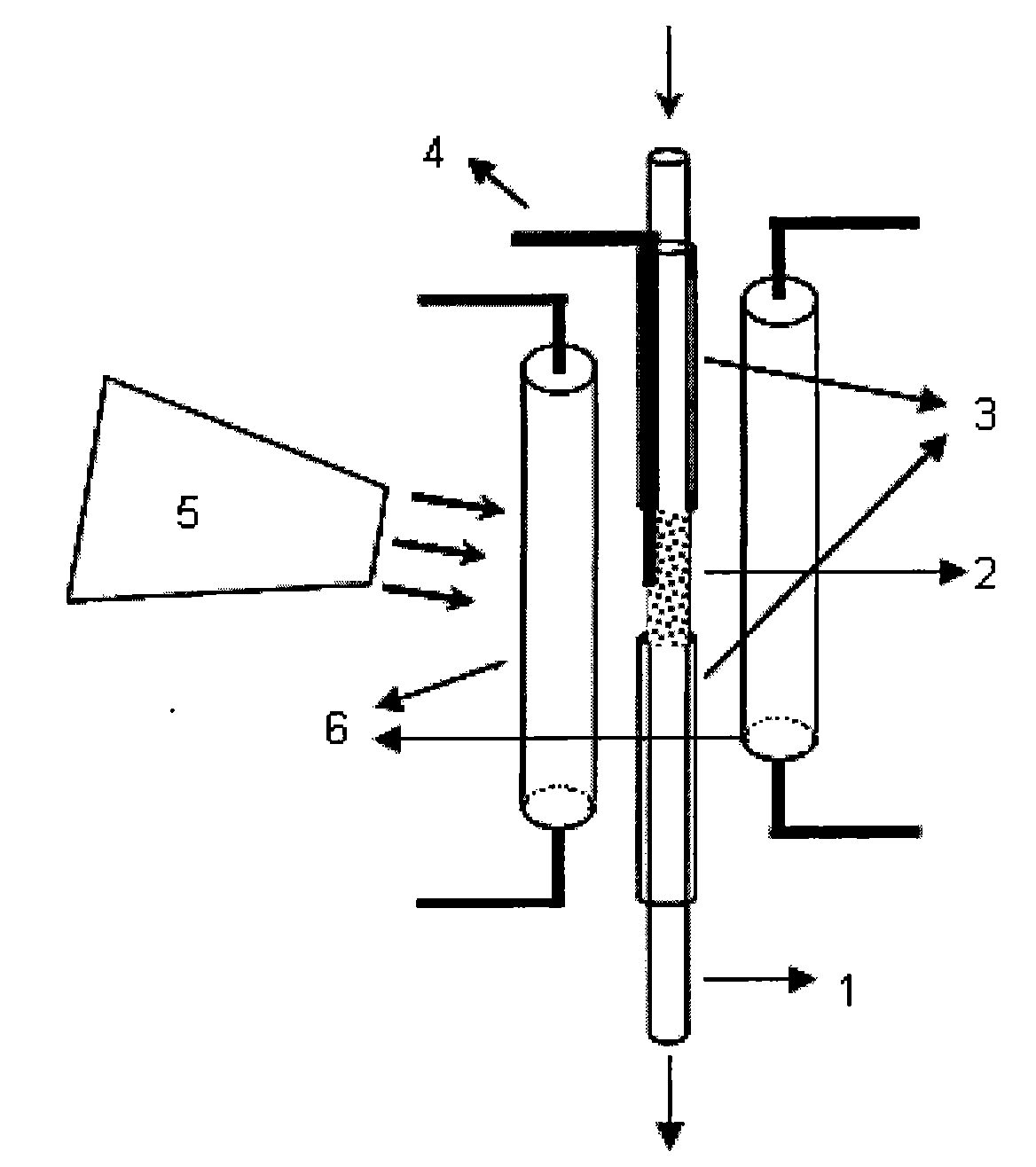

Method used

Image

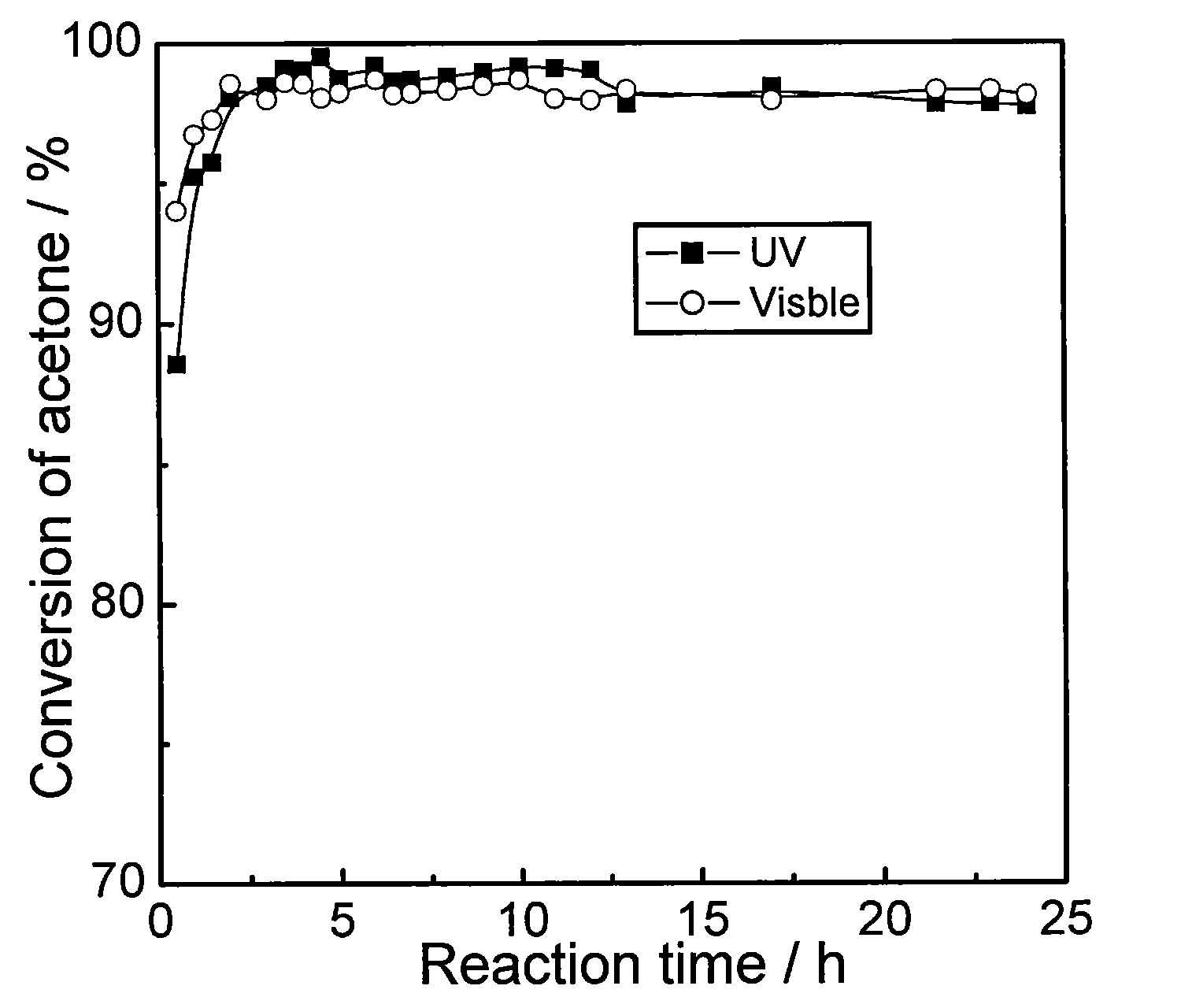

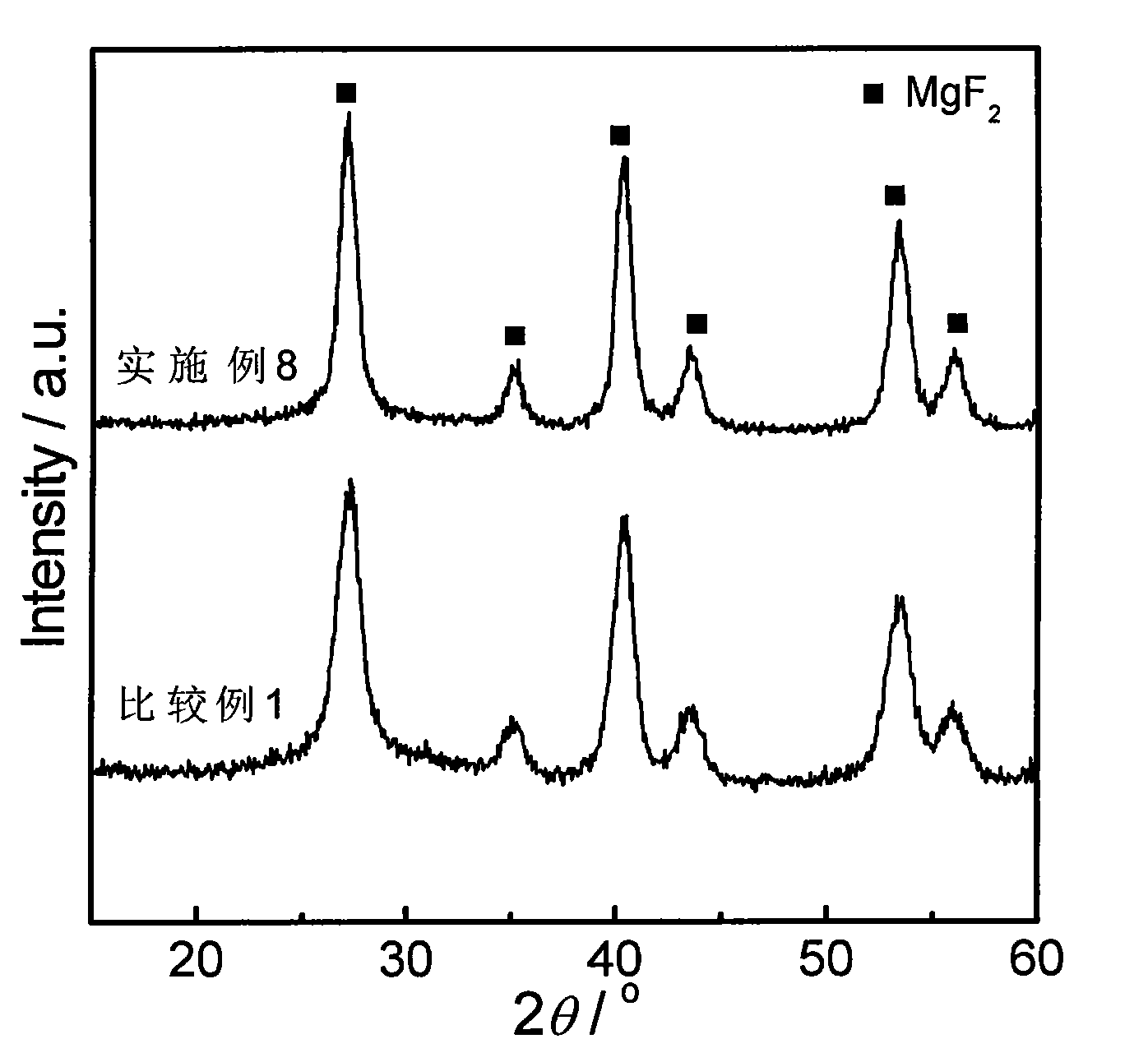

Examples

Embodiment 1

[0027] Weigh 10.0g of magnesium nitrate and 2.88g of ammonium fluoride, dissolve them in 20ml and 10ml of deionized water respectively, and slowly add the ammonium fluoride solution dropwise into the magnesium nitrate solution under stirring to obtain a colorless colloidal liquid I. Weigh 0.069g of ammonium molybdate, dissolve it in 10ml of deionized water, add 0.6ml of ammonium sulfide solution, and stir to obtain light red solution II. The solution II was slowly added dropwise to the mixture I while stirring, and after mixing evenly, the water in the solution was removed by rotary evaporation at 80°C, and the obtained solid was dried in an oven at 90°C overnight. The dried precursor was calcined at 400°C for 2 hours in a nitrogen atmosphere, and S-1%MoO was obtained after natural cooling. x / MgF 2 catalyst.

Embodiment 2

[0029] Weigh 10.0 g of magnesium nitrate and 2.88 g of ammonium fluoride, dissolve them in 20 ml and 10 ml of deionized water respectively, slowly add the ammonium fluoride solution dropwise into the magnesium nitrate solution under stirring, and obtain a colorless colloidal liquid I. Weigh 0.344g of ammonium molybdate, dissolve it in 10ml of deionized water, add 3.2ml of ammonium sulfide solution, and stir to obtain red solution II. The solution II was slowly added dropwise to the mixture I while stirring, and after mixing evenly, the water in the solution was removed by rotary evaporation at 80°C, and the obtained solid was dried in an oven at 90°C overnight. The dried precursor was calcined at 400°C for 2 hours in a nitrogen atmosphere, and S-5%MoO was obtained after natural cooling. x / MgF 2 catalyst.

Embodiment 3

[0031] Weigh 10.0g of magnesium nitrate and 2.88g of ammonium fluoride, dissolve them in 20ml and 10ml of deionized water respectively, and slowly add the ammonium fluoride solution dropwise into the magnesium nitrate solution under stirring to obtain a colorless colloidal liquid I. Weigh 0.482g of ammonium molybdate, dissolve it in 10ml of deionized water, add 4.6ml of ammonium sulfide solution, and stir to obtain dark red solution II. The solution II was slowly added dropwise to the mixture I while stirring, and after mixing evenly, the water in the solution was removed by rotary evaporation at 80°C, and the obtained solid was dried in an oven at 90°C overnight. The dried precursor was calcined at 400°C for 2 hours in a nitrogen atmosphere, and S-7%MoO was obtained after natural cooling. x / MgF 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com