Method of and apparatus for controlling excitation

A technology of exciter and excitation control, which is applied in the direction of control system, control of generator, control of generator through magnetic field change, etc. It can solve the problems of reducing the rating of the generator, affecting the active material and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

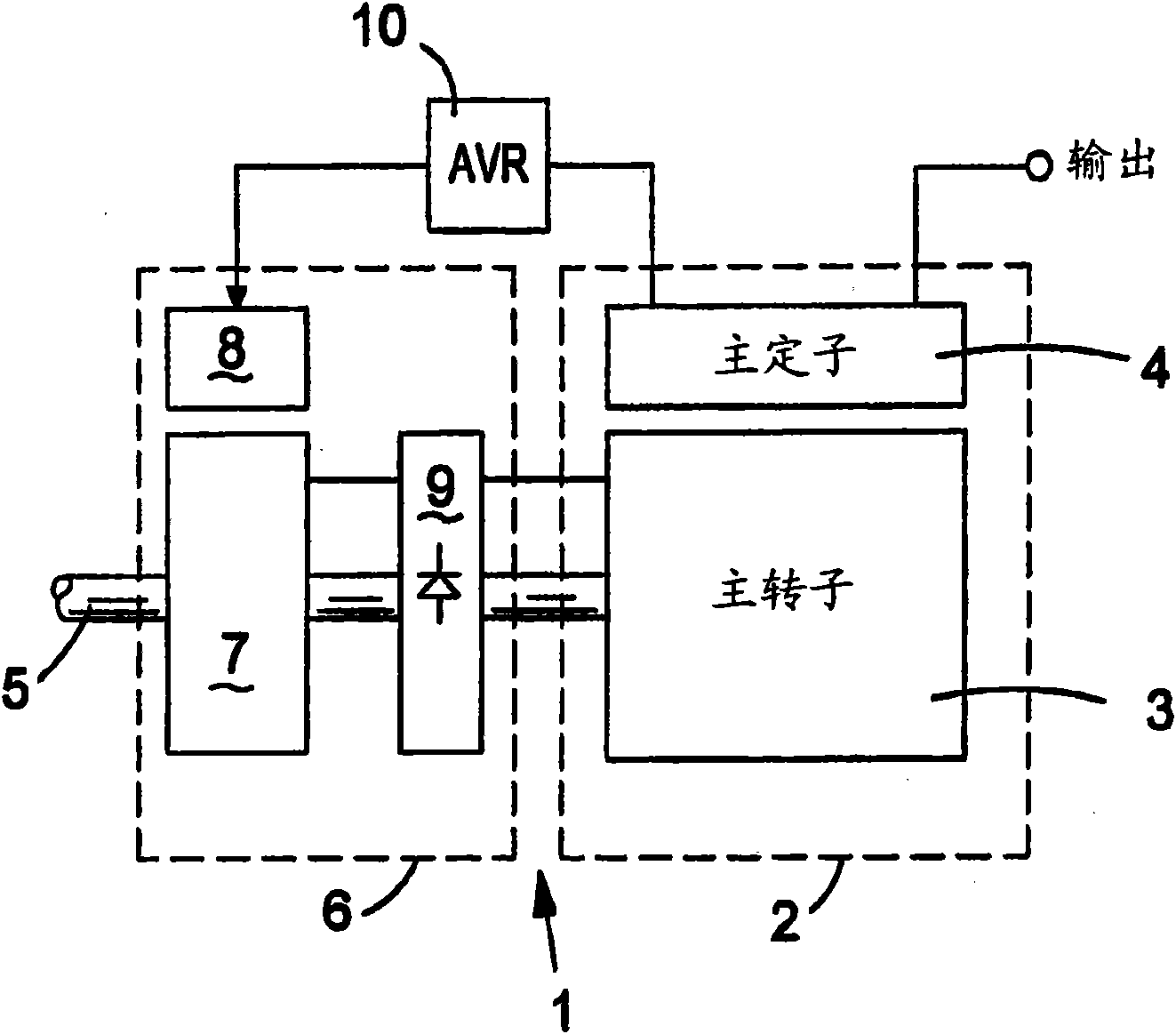

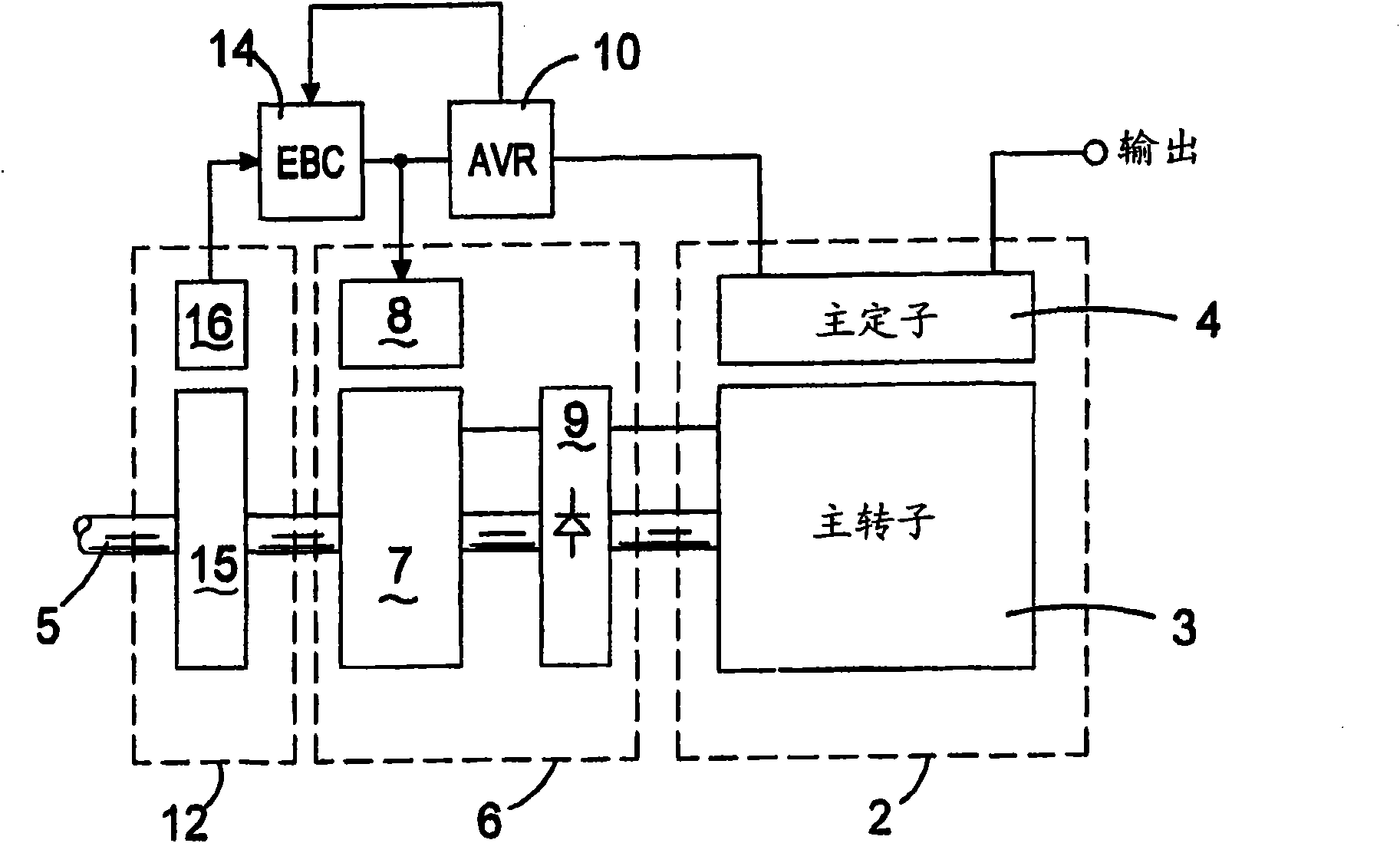

[0038] figure 1 The components of the synchronous generator 1 are shown. The generator includes a main engine 2 which includes a main rotor 3 and a main stator 4. The main rotor 3 is located on a shaft 5, which is driven by a prime mover such as a diesel engine (not shown). The main rotor generates a magnetic field so that rotation of the main rotor relative to the main stator causes AC output in the main stator windings.

[0039] The main rotor is magnetized by passing a DC current through the rotor winding. This DC current is generated by an exciter 6 which includes an exciter rotor 7, an exciter stator 8 and a rotating diode 9. The exciter rotor 7 is mounted on the shaft 5, and the rotation of the exciter rotor 7 relative to the exciter stator 8 produces an AC output in the exciter rotor winding. This AC output is converted into DC by the rotating diode 9 and the DC output of the rotating diode is fed to the main rotor 3.

[0040] in figure 1 In the arrangement, the power fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com