Small-size multi-way valve operating mechanism assembly

A control mechanism, multi-way valve technology, applied in the direction of valve operation/release device, valve detail, valve device, etc., can solve the problems of large volume, large space, and inability to control the direction or position of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can be explained in more detail with reference to the following examples; however, it should be noted that the present invention is not limited to the following examples.

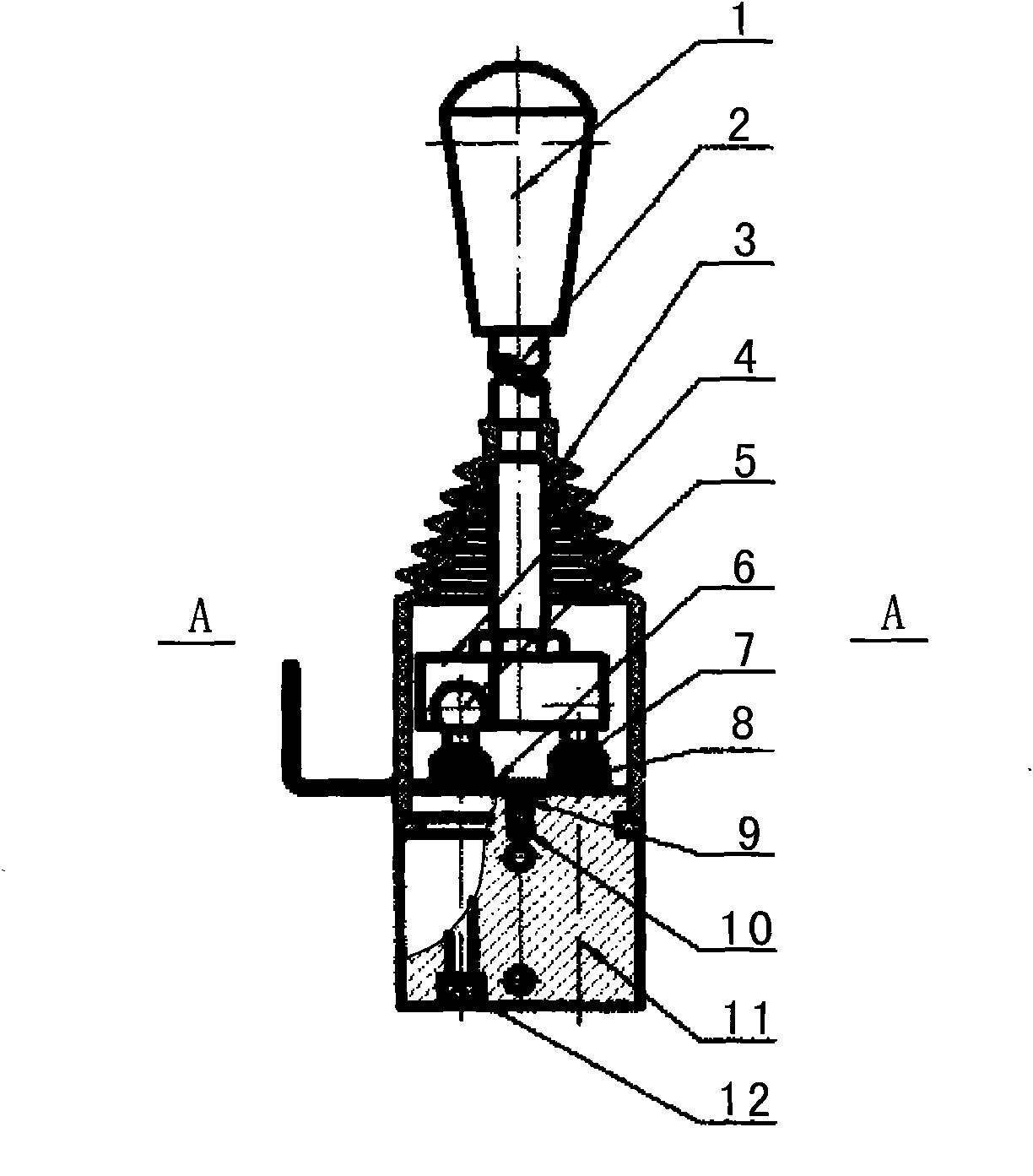

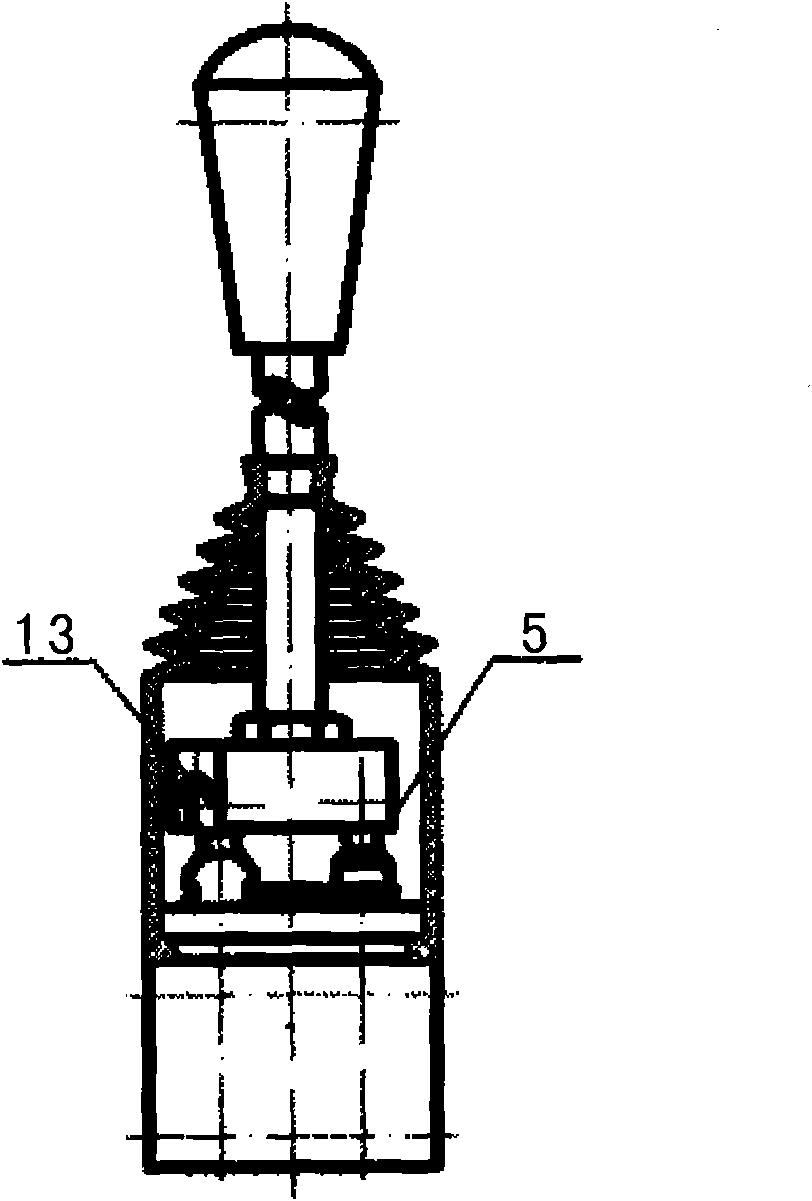

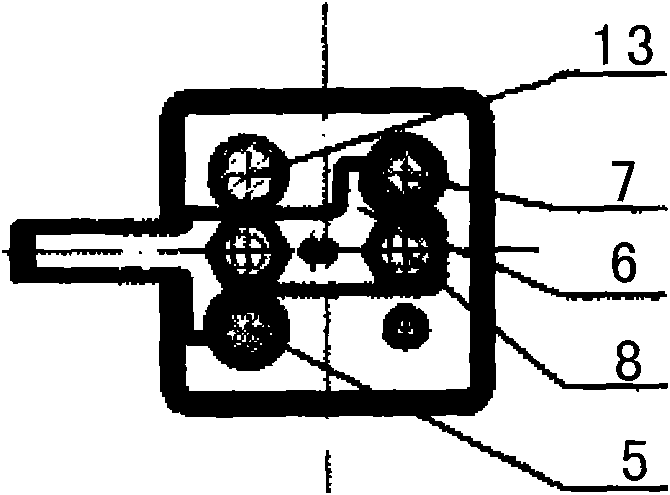

[0015] exist figure 1 , 2 , The small multi-way valve control mechanism assembly described in 3, the control handle 1 is arranged on the upper end of the handle bar 2, and a dust-proof rubber sheath 3 is set on the lower part of the handle bar 2, and the lower part of the dust-proof rubber sheath 3 is a The side of the side is provided with a through hole, and the lower end of the dustproof rubber sheath 3 is stuck on the upper part of the controller base 11. The dustproof rubber sheath 3 is a cavity structure, and it is characterized in that: the lower end of the handle rod 2 is in the dustproof rubber sheath. The cover 3 is connected to the upper surface of the handle rocker seat 4, and the lower part of the handle rocker seat 4 is provided with two hole-type chute correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com