Bottle body with reinforcing ribs

A rib and bottle body technology, applied in the field of bottle body with ribs, can solve the problems of difficult to meet the strength requirements of the bottle body and high manufacturing cost, and achieve the effects of improving market competitiveness, saving materials, and reasonable surface design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

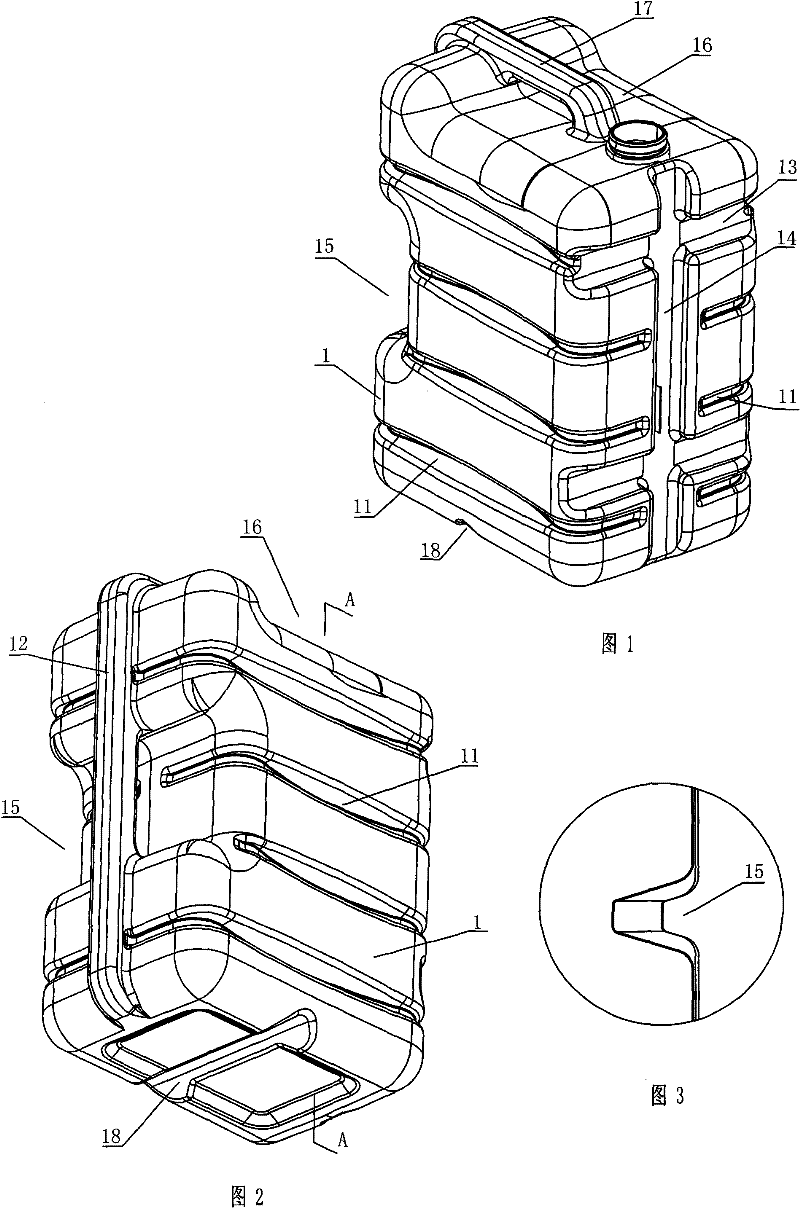

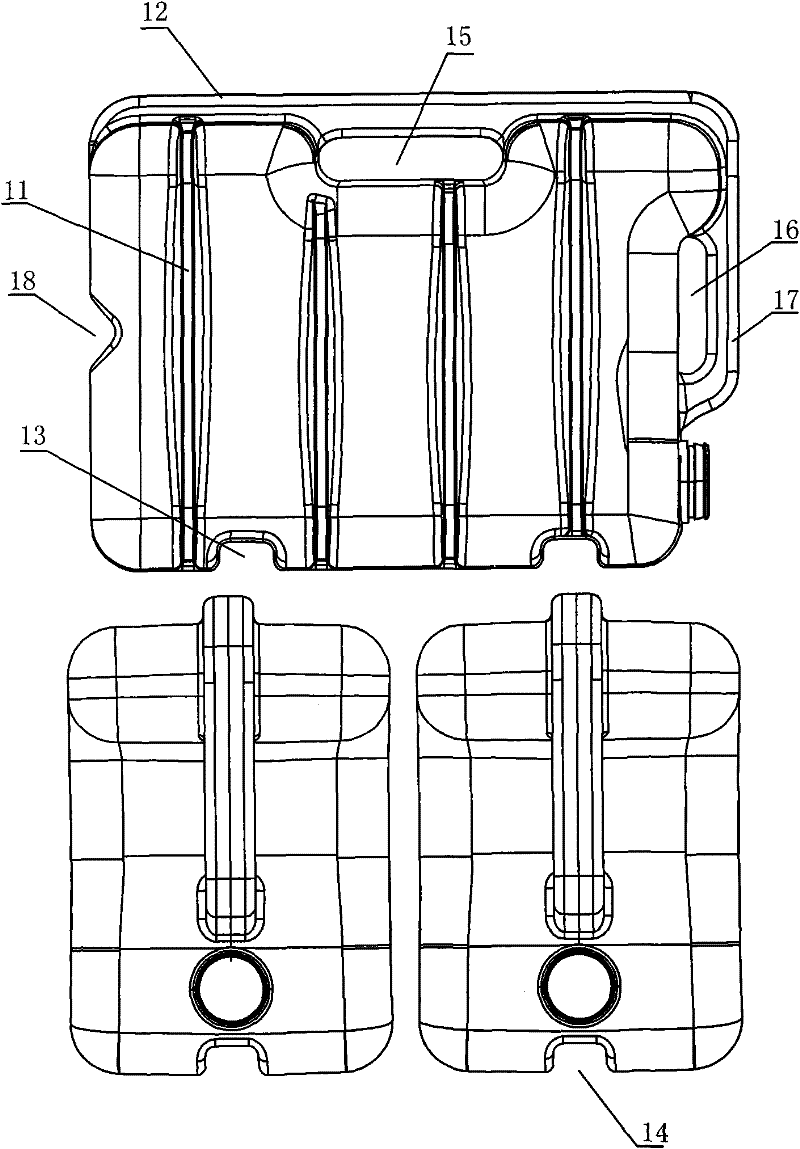

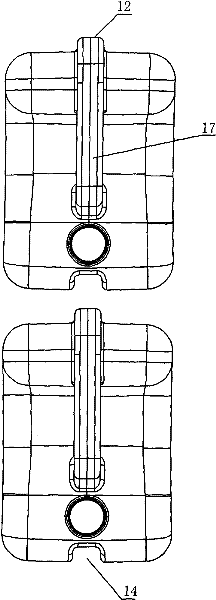

[0016] refer to Figure 1 to Figure 3 As shown, a bottle body with reinforcing ribs includes a bottle body 1, the surface of the bottle body 1 is provided with concave reinforcing ribs 11, and the inner groove of part of the reinforcing ribs 11 is arc-shaped, and the arc shape is in the width In terms of size, it is a transitional surface with a wide middle and narrow sides; in terms of depth, it is a transitional surface with a deep middle and shallow sides; the width of the bottom of the inner groove is smaller than the width of the groove at the top. The structure of this design is reasonable. When the bottle is filled with liquid, the side of the bottle will not be easily deformed due to the above-mentioned curved surface-shaped reinforcing ribs, so that the bottle can be made thinner while meeting the strength requirements. , reducing the production cost of the product. The strengthening effect of this design is more obvious for the side with larger area.

[0017] The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com