Software for simulation and optimum design of warm-hot formation

A technology of warm forming and optimized design, which is applied in computing, special data processing applications, instruments, etc., and can solve the problems of cold stamping forming process that cannot be formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

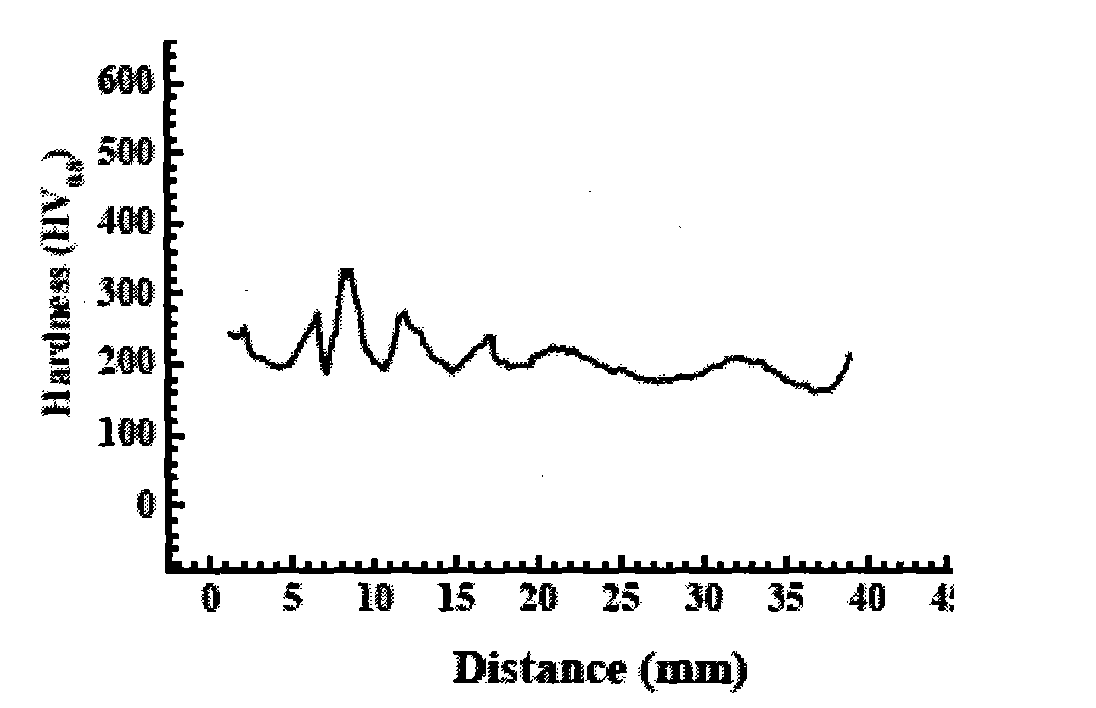

[0015] In the warm forming simulation, establish the CAE analysis model of the mold, input the thermodynamic parameters of the material at different temperatures or the material model provided by the application software itself, and then input the relevant process parameters, contact conditions and select the corresponding calculation method, etc., to complete the above Perform numerical calculations after the operation, and finally view the obtained simulation results in the software post-processing interface, for example figure 2 , image 3 , Figure 4 , Figure 5 shown.

[0016] On the basis of the above warm forming simulation, the optimal design of warm forming is carried out to obtain the best process parameters and mold design scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com