Manufacturing method of cutting nozzle applied to welding gun

A production method and cutting nozzle technology, which are applied in the combustion method, gas fuel burner, combustion type and other directions, can solve the problems of increased power consumption, irregular shape of internal holes, large power consumption, etc., to reduce power consumption, The effect of simplifying the annealing process and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

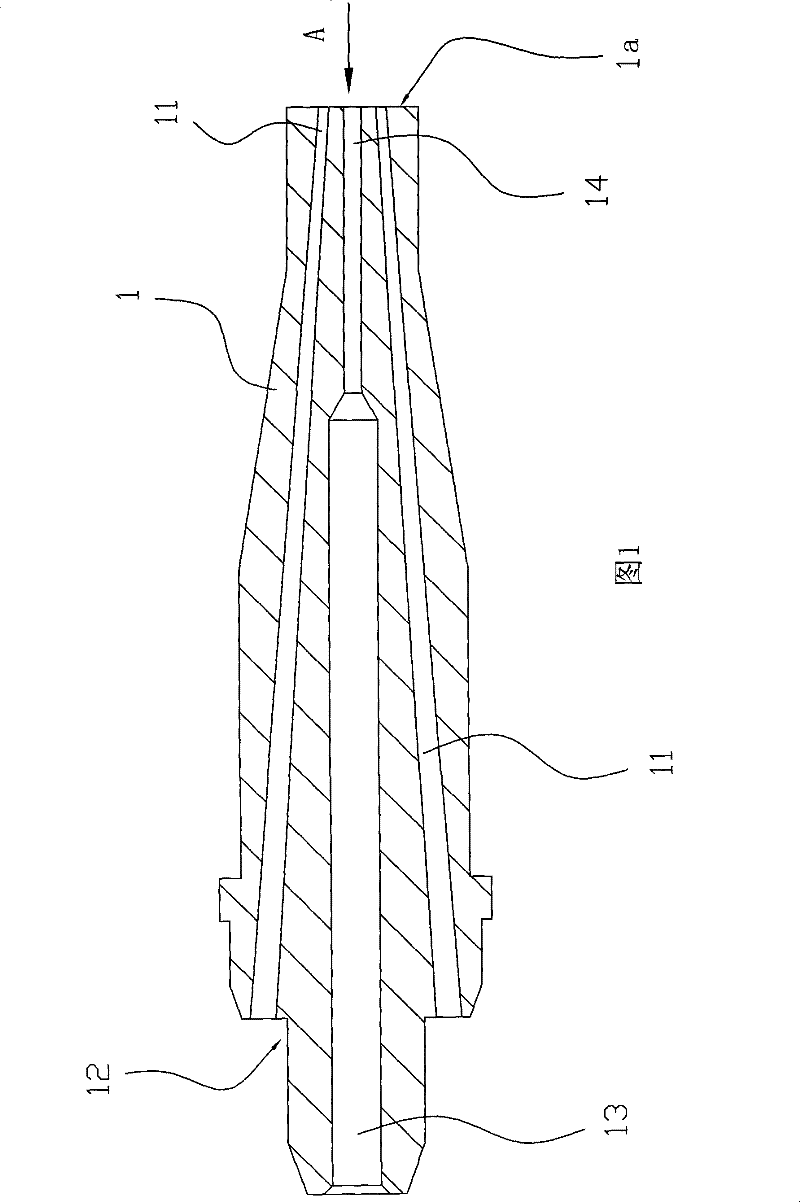

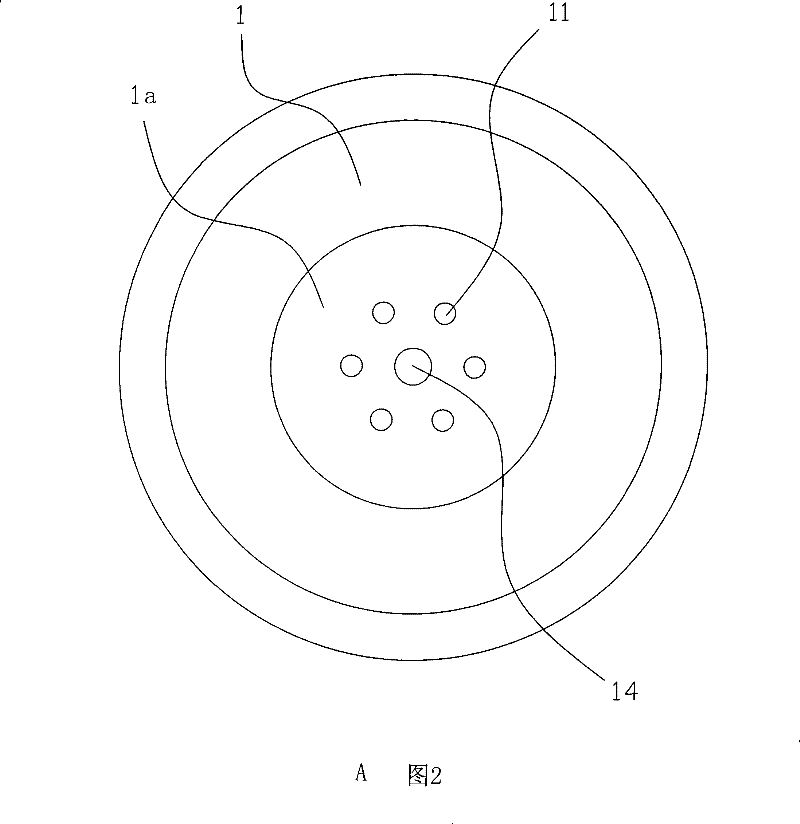

[0018] Such as Figure 1 to Figure 3 As shown, the cutting nozzle used on the welding and cutting torch of this embodiment includes a cutting nozzle body 1, the cutting nozzle body 1 is made of tellurium copper material, and the vent hole on the cutting nozzle body 1 adopts a drilling machine or a machine tool Drilled. The tellurium content in the tellurium copper material is 0.3-3% by mass.

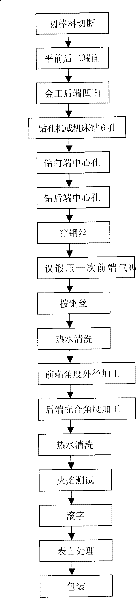

[0019] The manufacturing method of the cutting nozzle includes the following steps: material selection, forging and dimension processing, and is characterized in that: the ventilation hole on the cutting nozzle is manufactured by adopting hoof copper material and combining the drilling process.

[0020] a. The material selection step is: select the round bar of tellurium copper and cut it off, flatten the front and rear ends, and then metalwork the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com