On-line raw material automatic control method of thin piece line

A technology of raw materials and flakes, which is applied in the field of automatic control of raw materials on the flake line, can solve the problems of time-consuming and labor-intensive, automatic logistics, etc., and achieve the effect of reducing failure rate, saving labor force, and reducing equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

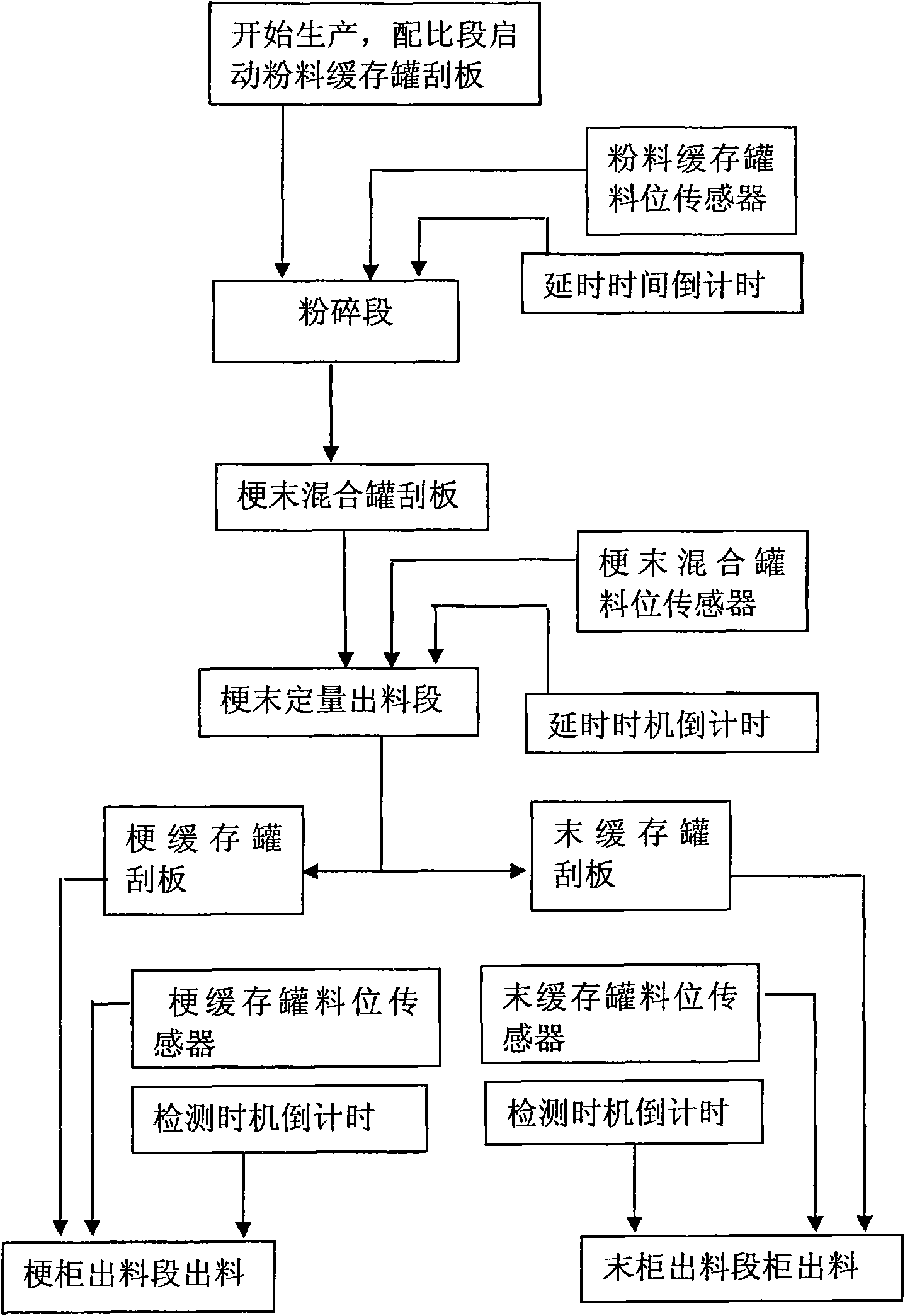

[0012] The automatic control method for online raw materials of the flake line first divides the raw material production equipment of the flake line from front to back into a proportioning section, a crushing section, a quantitative discharge section at the end of stems, and a stem cabinet according to the on-site equipment and the characteristics of material storage and processing. In the discharge section and the end cabinet discharge section, each section is equipped with a material buffer tank, the proportioning section is equipped with a powder buffer tank, the crushing section is equipped with a pulverizer and a stem end mixing tank, and the stem end quantitative discharge section is equipped with a stem buffer There are material level sensors in each tank and the final buffer tank to detect the material level, and each tank is equipped with a discharge scraper. The material level sensor adopts the rotary type material level sensor. In order to improve the control accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com