Energy-saving and emission-reducing sow gestation hut in the north

A northern energy-saving and sow technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of large sewage discharge, poor light in pig houses, and peculiar smell, and achieve the effect of preventing heat stroke in sows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment, again the present invention will be further described:

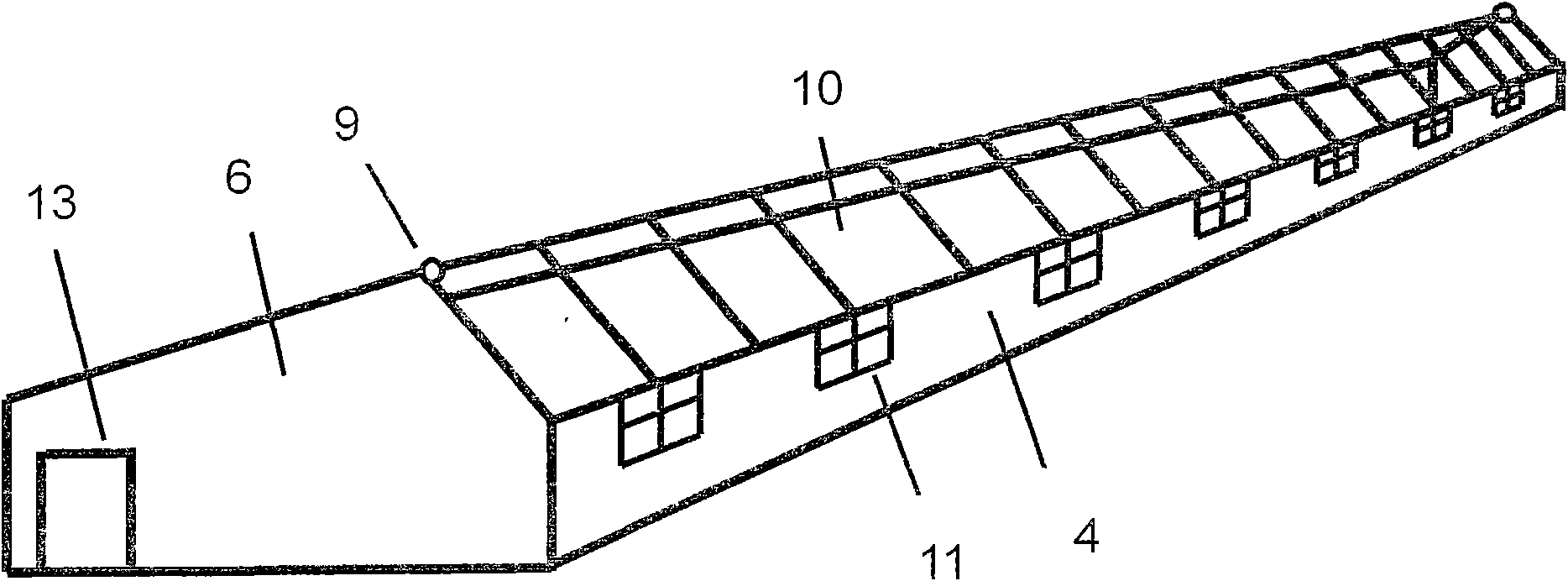

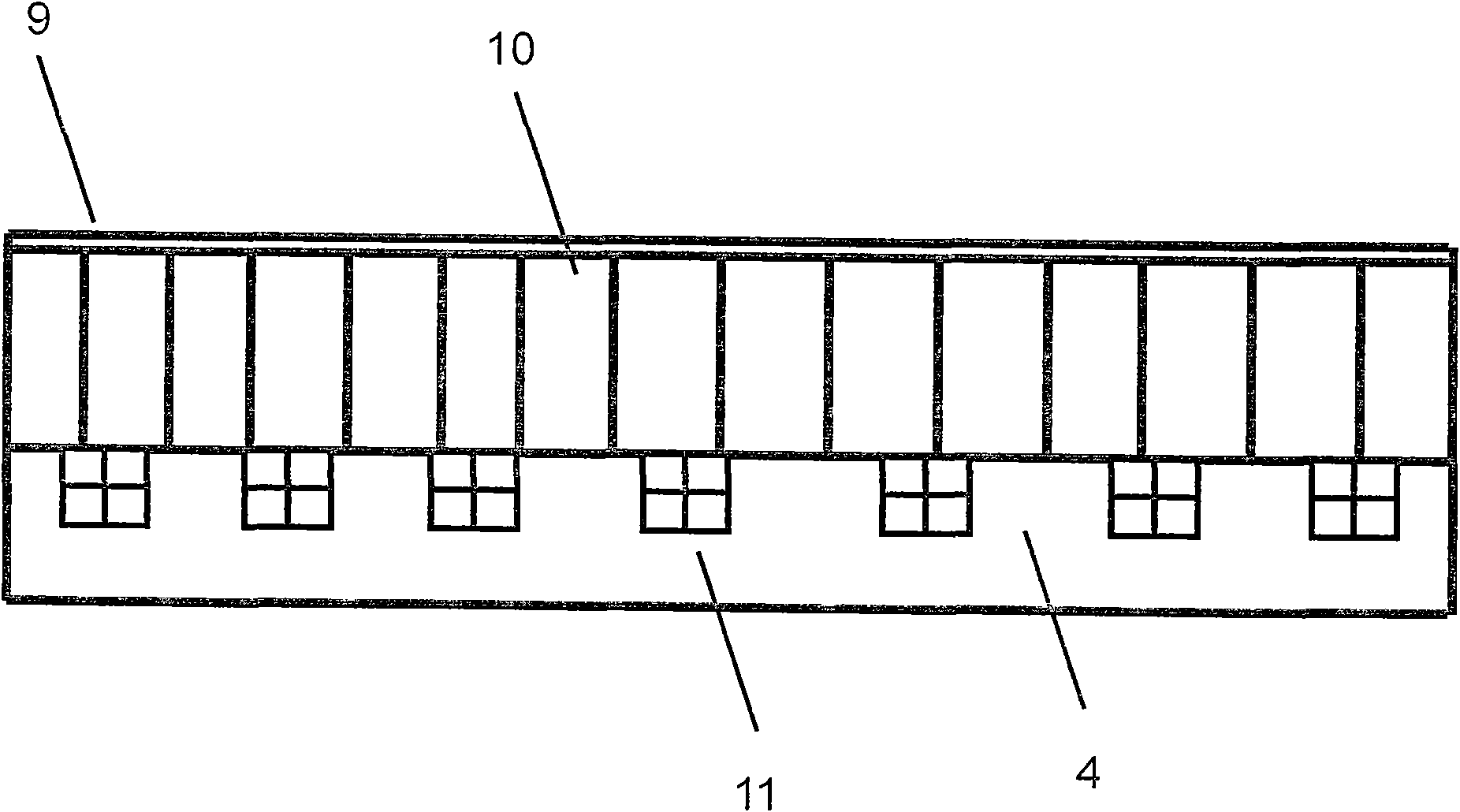

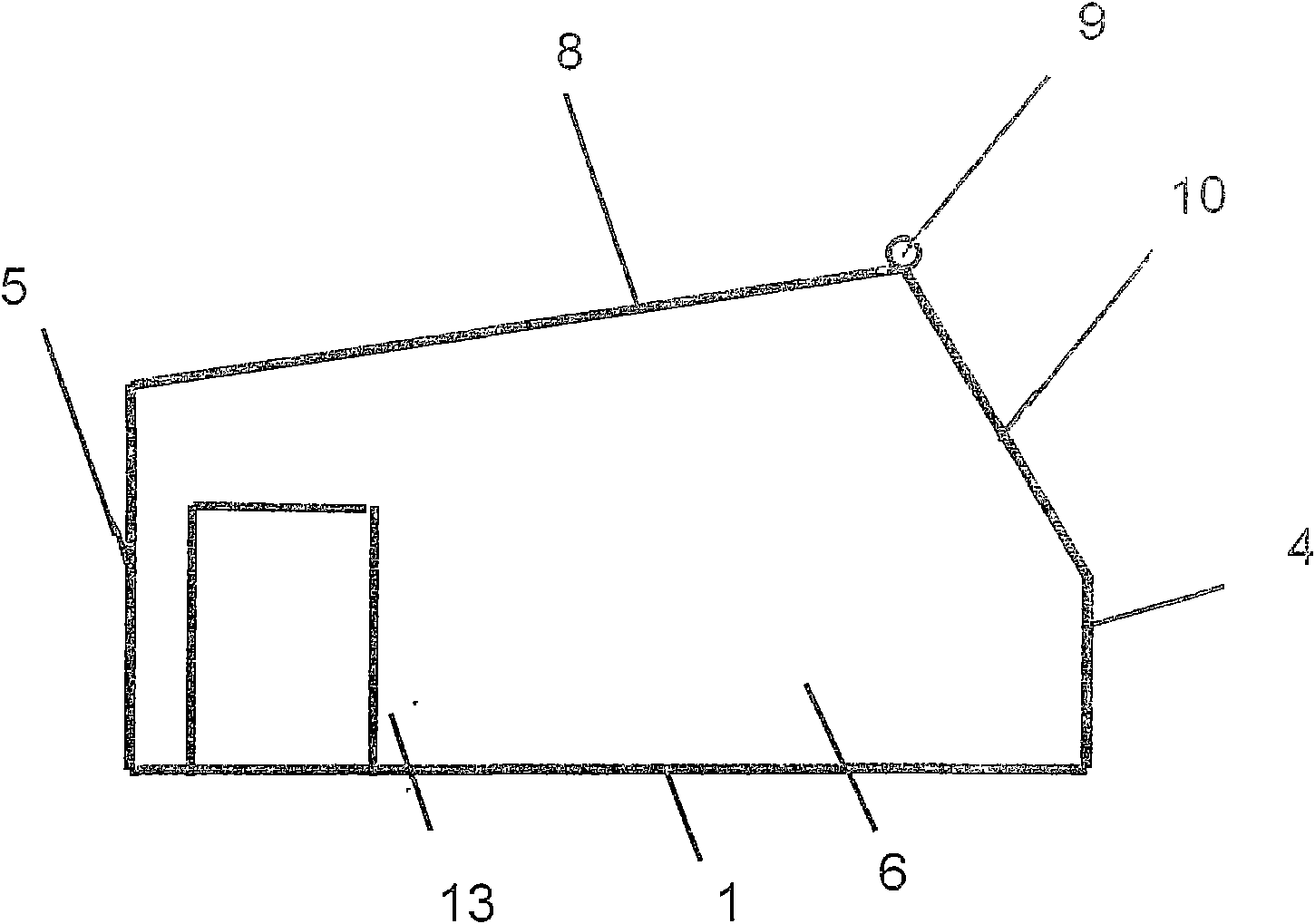

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a northern energy-saving and emission-reducing gestation house for sows includes a ground 1, a trench 2, a slatted floor 3, a south wall 4, a north wall 5, a west gable 6, an east gable 7, a sloping roof 8, an automatic roll Curtain 9, sunshine glass plate ceiling 10, window 11, limit bar 12, west side door 13, east side door 14, sewer cover 15 and sewer 16, on ground 1, pig house is made up of south wall 4, north wall 5 , west gable 6, east gable 7 encircle; The sloping roof 8 and the sunlight glass plate ceiling 10 ridge intersection places the automatic roller shutter 9; The angle between the intersection with the roof 10 of the sunny glass plate roof 10 is 110°, the 10 sunny glass plate roofs are located on the south wall 4, and the 8 slope roofs are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com