Method for replacing double/quadruple helix coil of transformer with long-circle section

A transformer coil, oblong type technology, applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, coil manufacturing, etc., can solve the problem of the geometric size of the oblong cross-section coil being out of tolerance, and achieve the manufacturing cost. Reduced, effect of good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

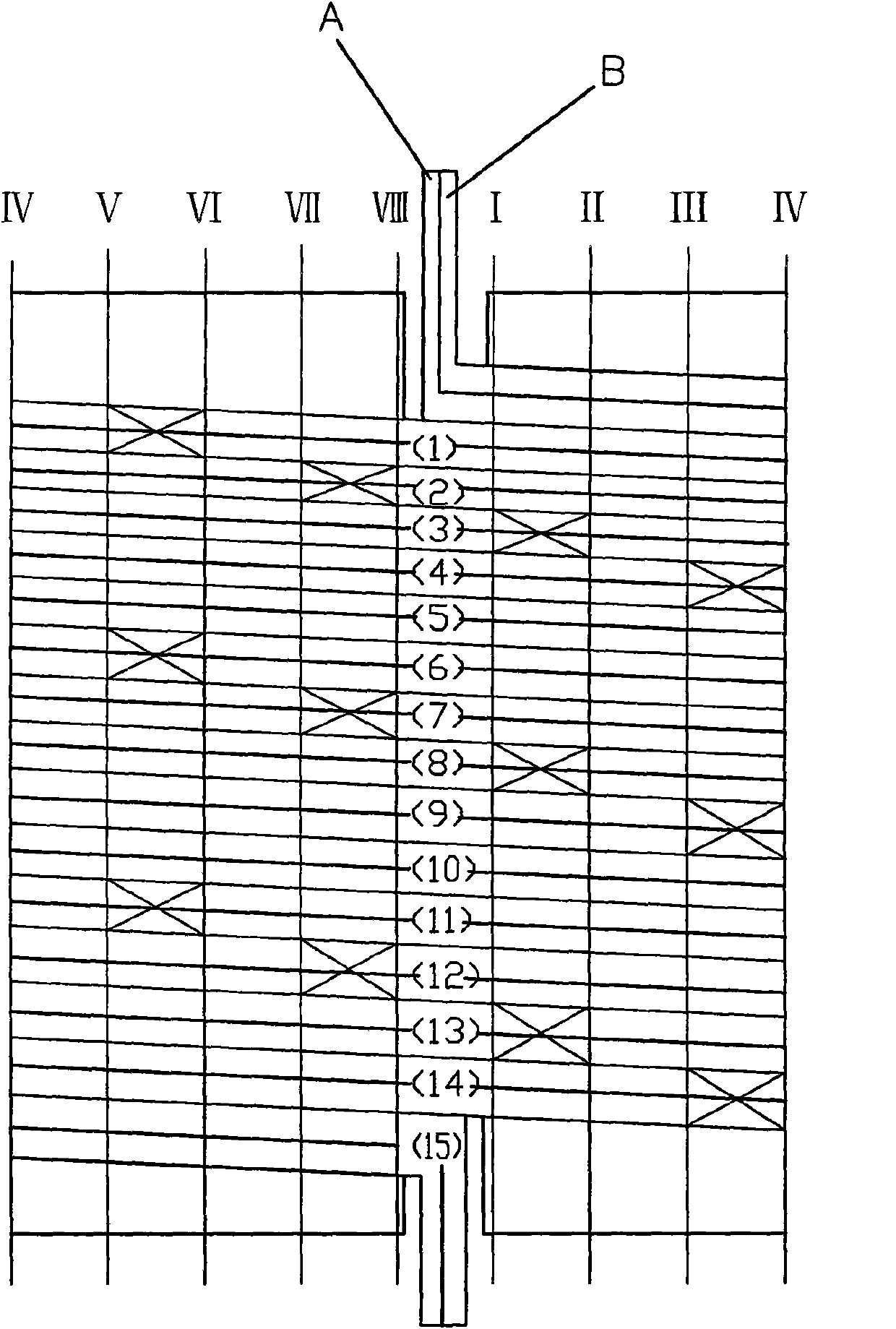

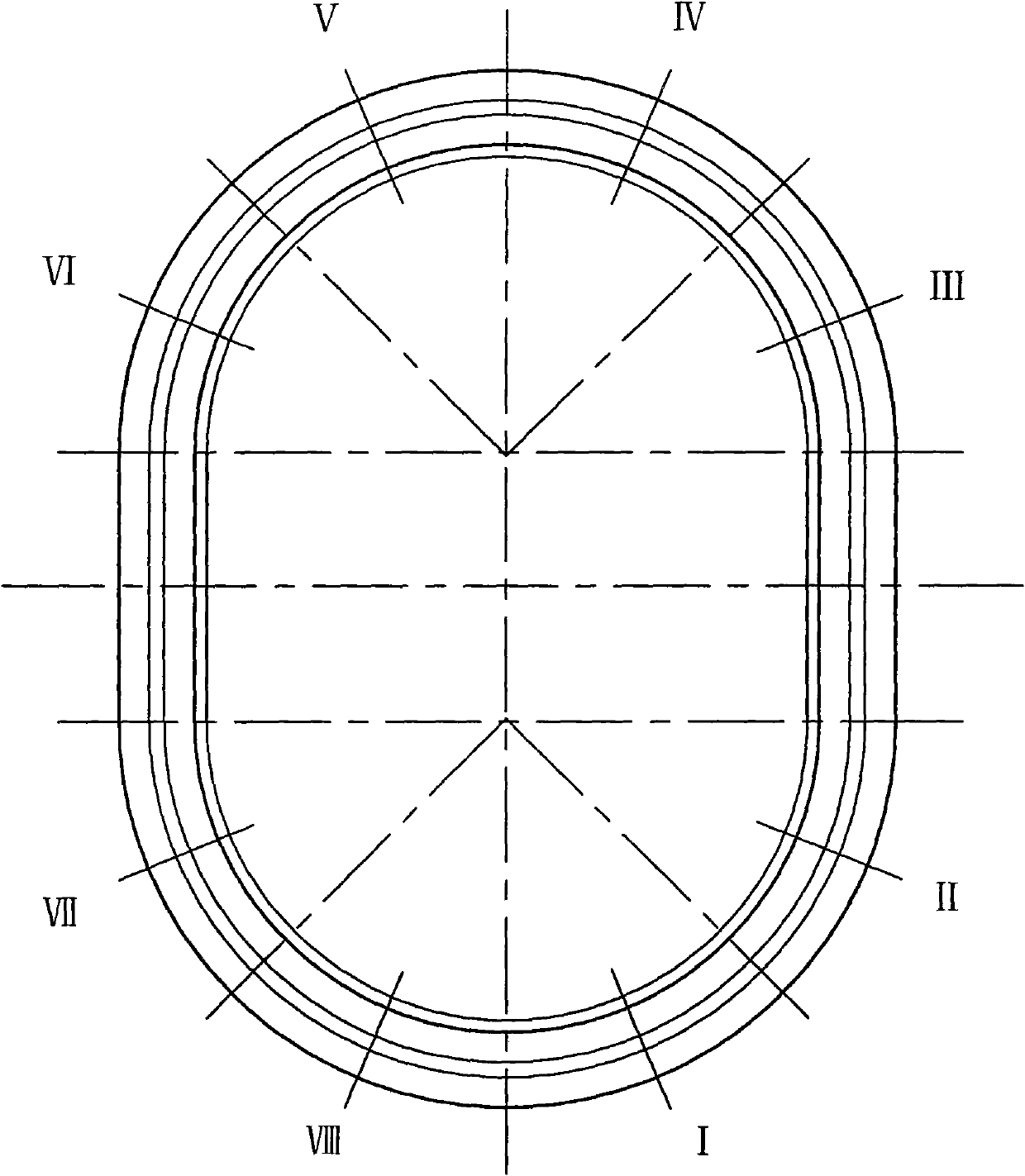

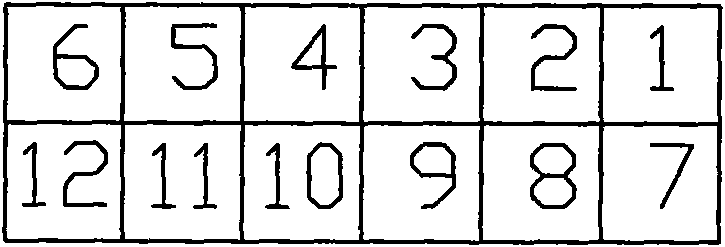

[0032] See attached Figure 1-15 , a double-helix transformer coil with oblong cross-section. There are 12 wires wound in parallel, arranged in 2 groups in the axial direction and 6 wires in the width direction. The labels of the twelve wires are respectively 1.2.3.4.5.6. 7.8.9.10.11.12, the cross-section of the coil wound along the oblong core is oblong, and the ratio of the length of the straight line part of the oblong cross-section of the coil to the length of the radius of the semicircular part is 1. The transposition steps are as follows:

[0033] (1) if figure 1 As shown, the 12 wires wound in parallel are axially divided into two groups of wire cakes, A and B, and each group of wire cakes is overlapped by 6 wires and wound along an iron core with an oblong cross section;

[0034] (2) The two semicircle parts of the cross section of the coil can be combined into a complete circle, and the circle formed by the two semicircle parts can be divided into 8 levels according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com