Packaging structure and manufacturing method thereof

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of poor heat dissipation performance, poor heat dissipation performance, and unsafety of packaging structures, so as to reduce the expansion coefficient and improve Effect of heat dissipation performance and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

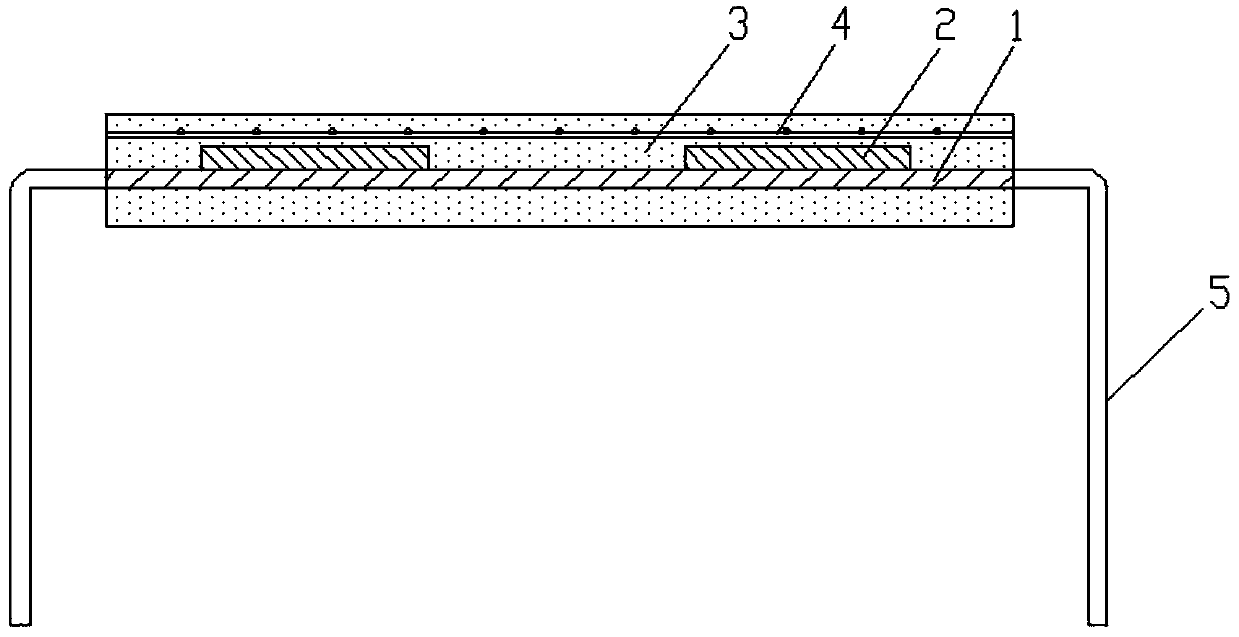

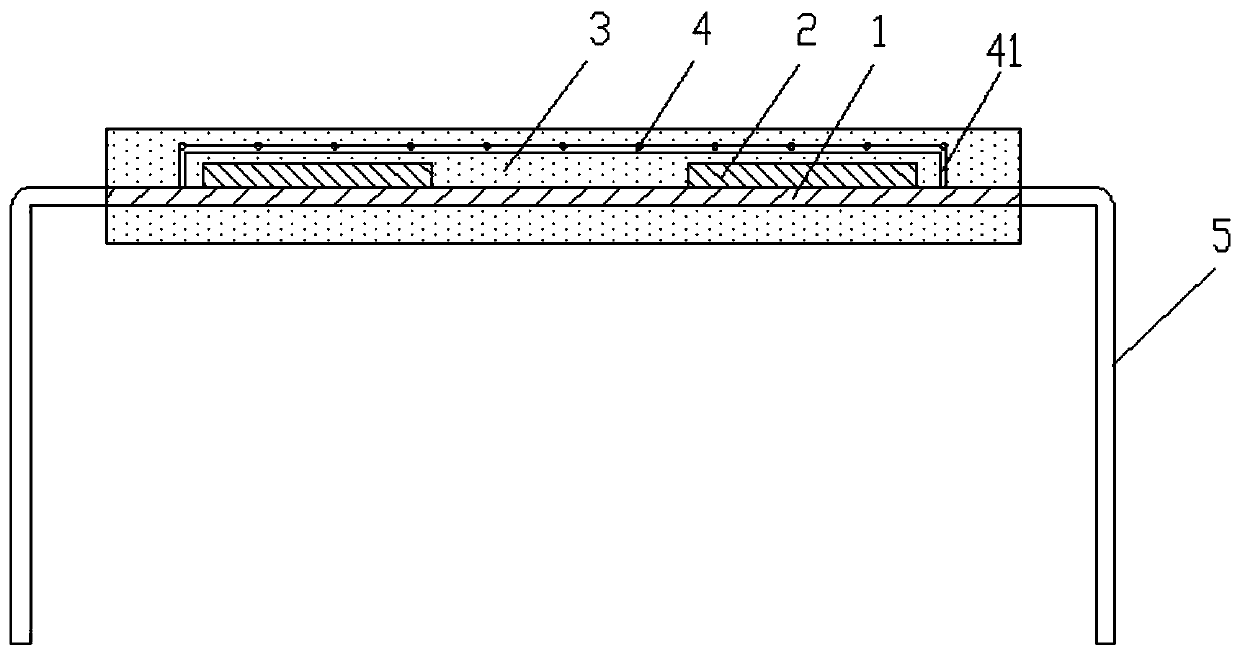

[0039] The packaging structure provided in this embodiment includes a heat-conducting bottom sheet 1 , a chip 2 , a molding material layer 3 and a heat-conducting net 4 . Wherein, the chip 2 is fixed on the heat conduction base 1 , and the connection point on the chip 2 is electrically connected to the pin 5 on the heat conduction base 1 . The heat conduction net 4 wraps the chip 2 and is not in contact with the chip 2, that is, the heat conduction net 4 is suspended above the chip 2. This packaging structure is not only suitable for the heat conduction net 4 made of non-conductive heat conduction material, but also especially suitable for The heat conduction mesh 4 (such as metal mesh) made of conductive heat conduction material will not cause a short circuit because the heat conduction mesh 4 is not in direct contact with the chip 2 . There are two ways to suspend the heat conduction net 4 above the chip 2: the first method is to use multiple fixing frames to fix the heat co...

Embodiment 2

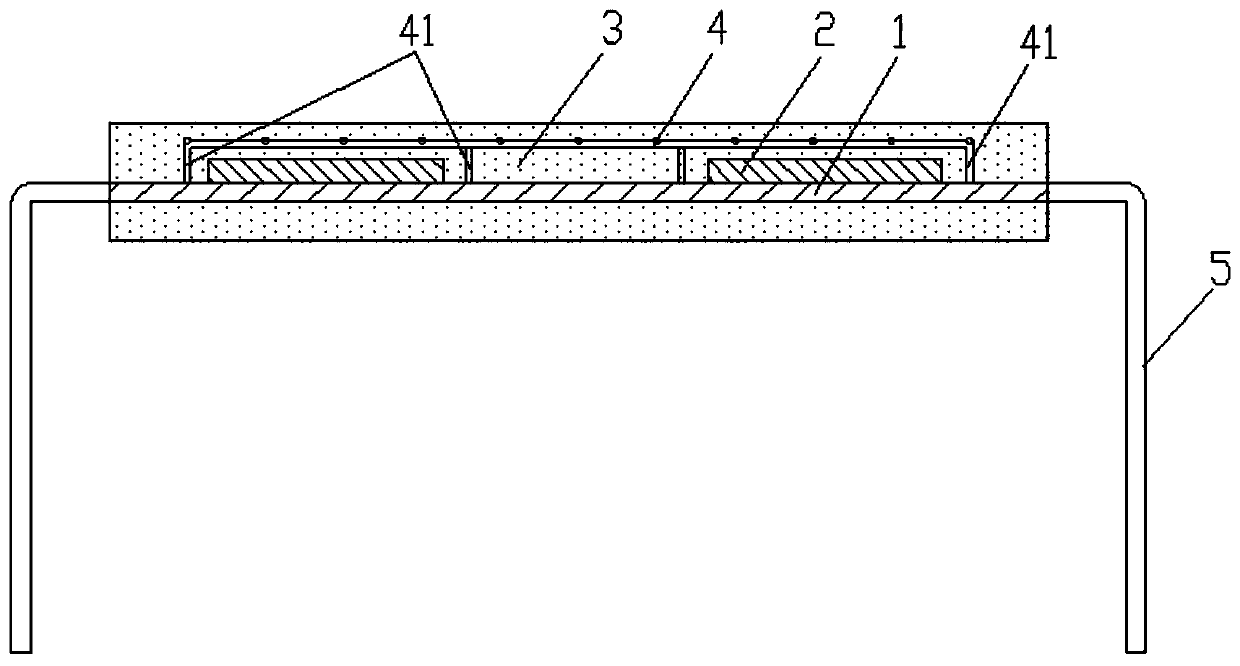

[0041] Such as Figure 4 As shown, the packaging structure provided in this embodiment includes a heat-conducting backsheet 1 , a chip 2 , a molding material layer 3 and a heat-conducting net 4 . Wherein, the chip 2 is fixed on the heat conduction base 1 , and the connection point on the chip 2 is electrically connected to the pin 5 on the heat conduction base 1 . The heat conduction net 4 wraps the chip 2 and is in contact with the chip 2, that is, the heat conduction net 4 is placed on the chip 2. This packaging structure has a simple structure of the heat conduction net 4 and only needs to place the heat conduction net 4 on the chip 2 before injection molding. That is, there is no need to add other fixing or supporting devices and steps, and the operation is simple. However, since the heat conduction net 4 is in direct contact with the chip 2, this packaging structure is only suitable for the case where the heat conduction net 4 is made of non-conductive heat conduction mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com