Method for detecting drying performance change of ink

An ink and performance technology, applied in the field of ink drying performance detection, can solve the problems of pattern peeling, printing sticky dirt, unable to truly reflect the change of ink drying performance, etc., and achieve the effect of improving printing work efficiency and reducing ink consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

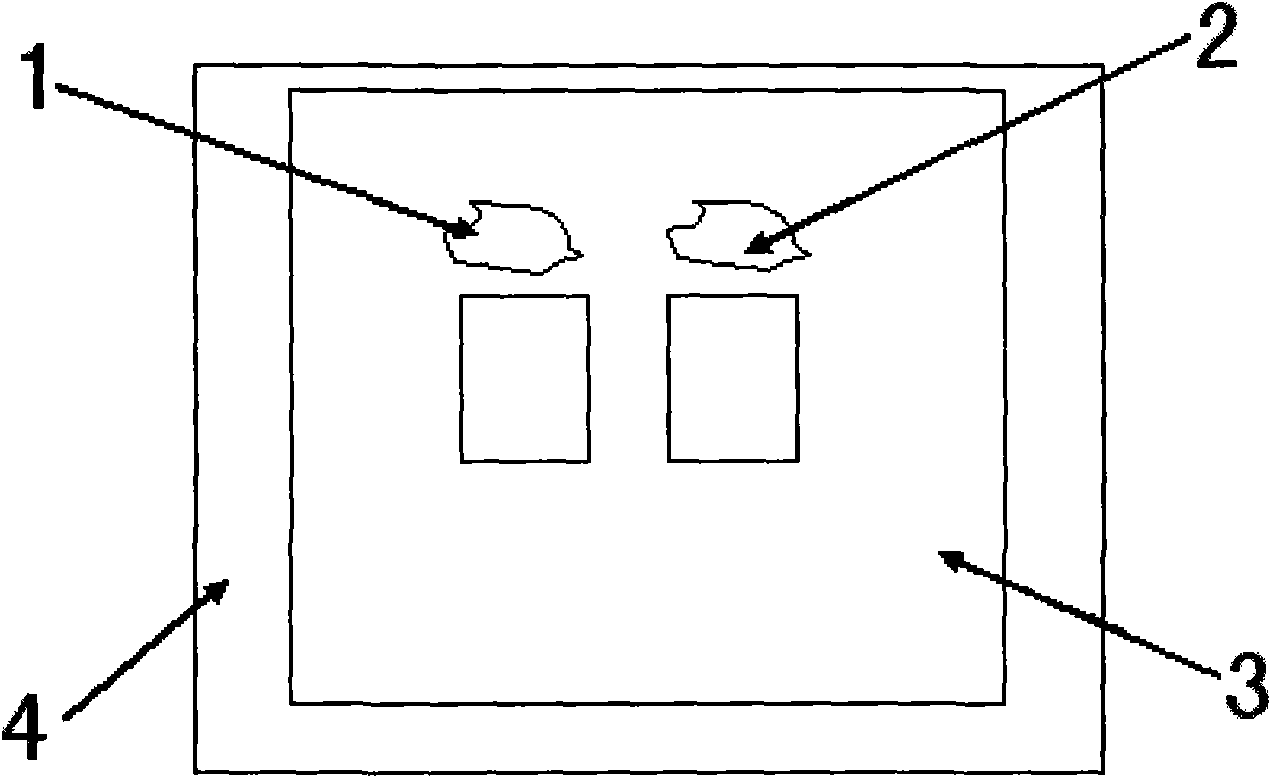

[0011] Such as figure 1 As shown, the present invention is realized in this way, and it is characterized in that the emulsified ink 2 and the original ink 1 are respectively placed above the polyester base 3 with two rectangular frames, and the polyester base 3 is cushioned with For paper 4, evenly scrape emulsified ink 2 and original ink 1 into the rectangular frame from top to bottom, remove the polyester film base 3, leave ink color blocks on paper 4, put the ink color blocks into a After 20 minutes in the oven, cover the scraping paper on the ink color block, use a mechanical constant force on each ink color block in the same direction for ten times, lift the scraping paper, and observe the sticking or dirt on the scraping paper Use a colorimeter to judge ink viscousness, and compare and judge the change of drying performance of several pieces of ink when one of the condition variables is changed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com