Three-row double-wire linear filling machine

A filling machine and linear technology, applied in the field of filling devices, can solve the problems of low degree of automation, easy overflow and leakage, difficult positioning of stacked bottles, etc., and achieve the effects of high degree of automation, improved filling efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

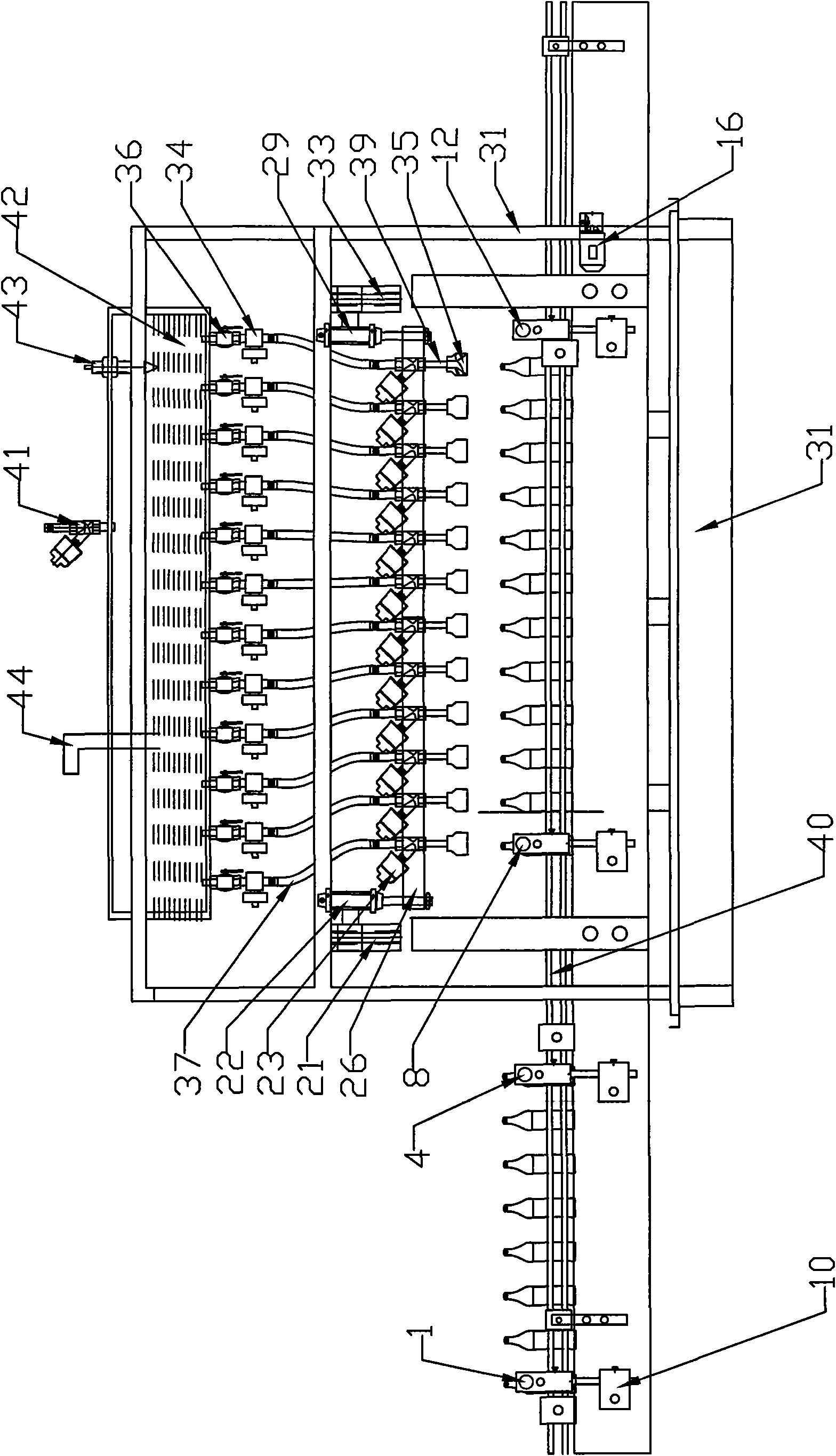

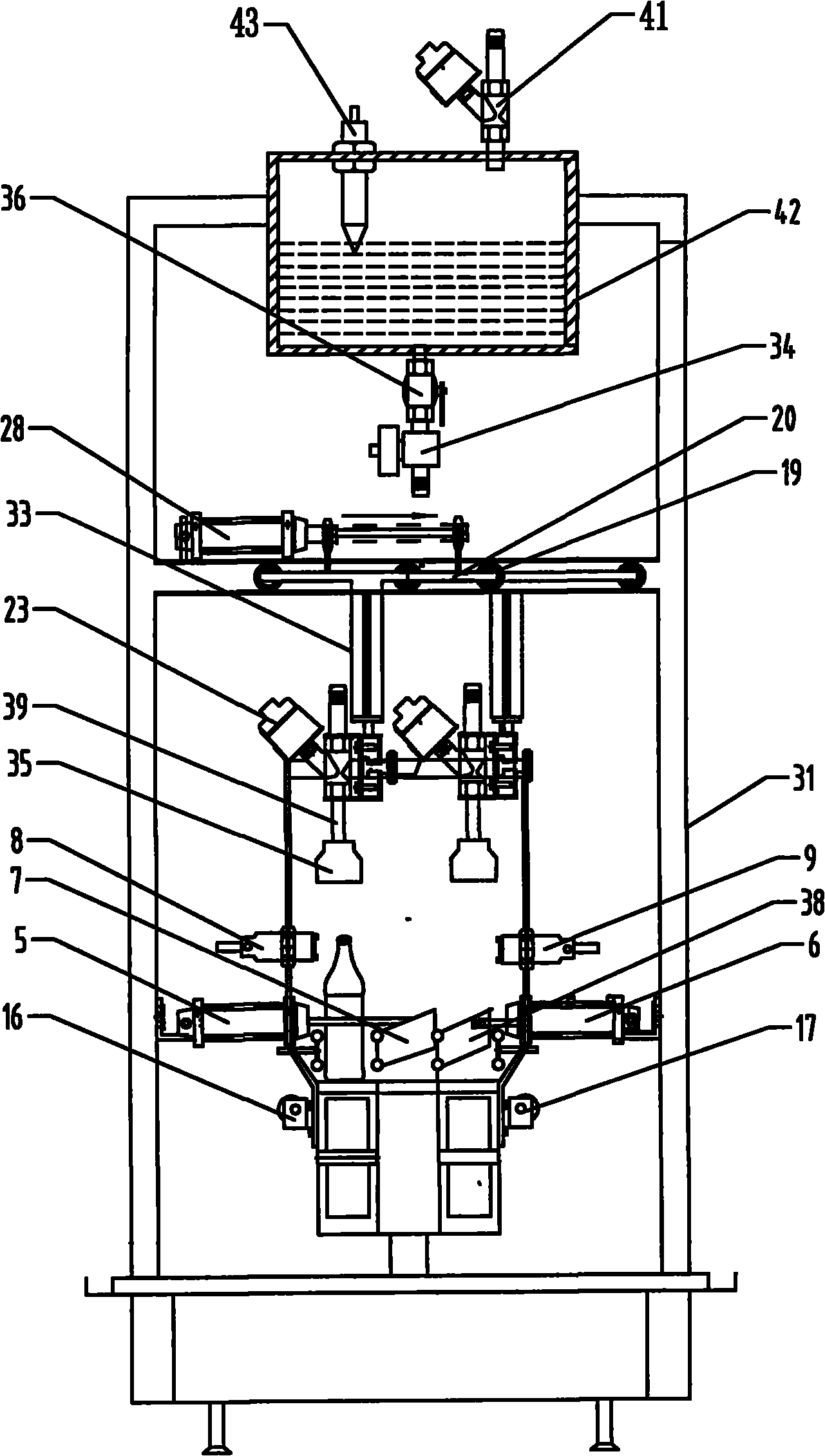

[0035] Example 1, such as figure 1 , figure 2 As shown, a three-column double-line linear filling machine includes a frame 31, and a bottle unscrambling and bottle feeding device and a liquid filling device are arranged on the frame 31, and the bottle unscrambling and bottle feeding device includes three bottles arranged side by side. There are three rows of conveyor belts, and a line changing device is installed between the three rows of conveyor belts.

[0036]The three rows of conveyor belts are respectively the first conveyor belt A, the second conveyor belt B and the third conveyor belt C, the first conveyor belt A is the longest, and its two ends extend to the outside of the frame 31, and it extends to the frame 31 The outer part has at least the length that can accommodate a plurality of bottles required for one-time filling side by side. Conveying guardrails 40 are respectively arranged on both sides of the extension part, and the first conveyor belt A is formed by t...

Embodiment 2

[0052] Example 2, such as Figure 6 As shown, the present invention can also set a plurality of third bottles corresponding to the positions of the bottles on the second conveyor B and the third conveyor C on the outside of the second conveyor B and the third conveyor C The baffle cylinder 11 and the fourth bottle body baffle cylinder 13 constitute the cylinder positioning of one bottle and one gear, which solves the difficult problem of stacking bottles of special-shaped bottles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com