The heating structure by warm water which using of dry process and the construction method thereof

A dry construction, hot water technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

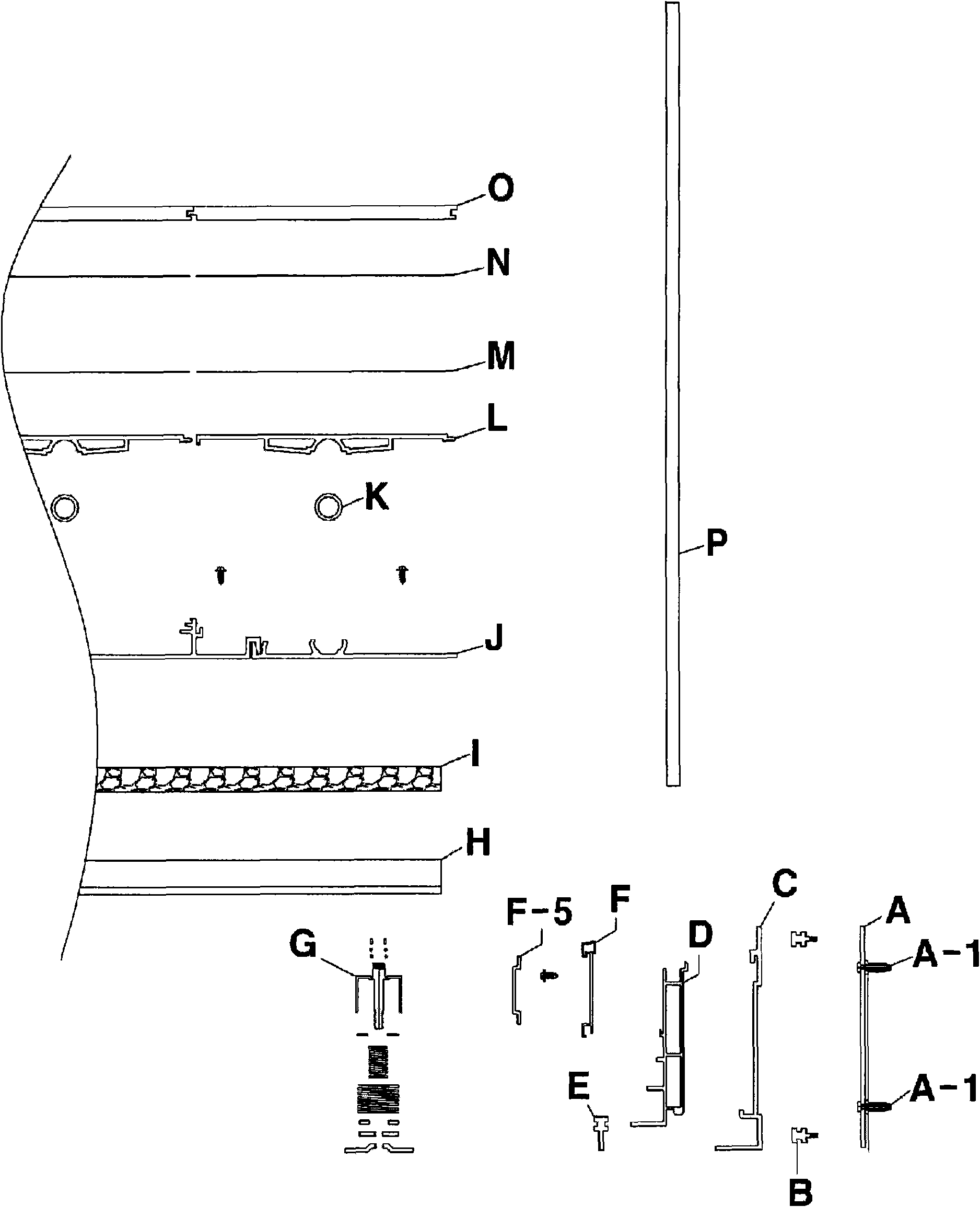

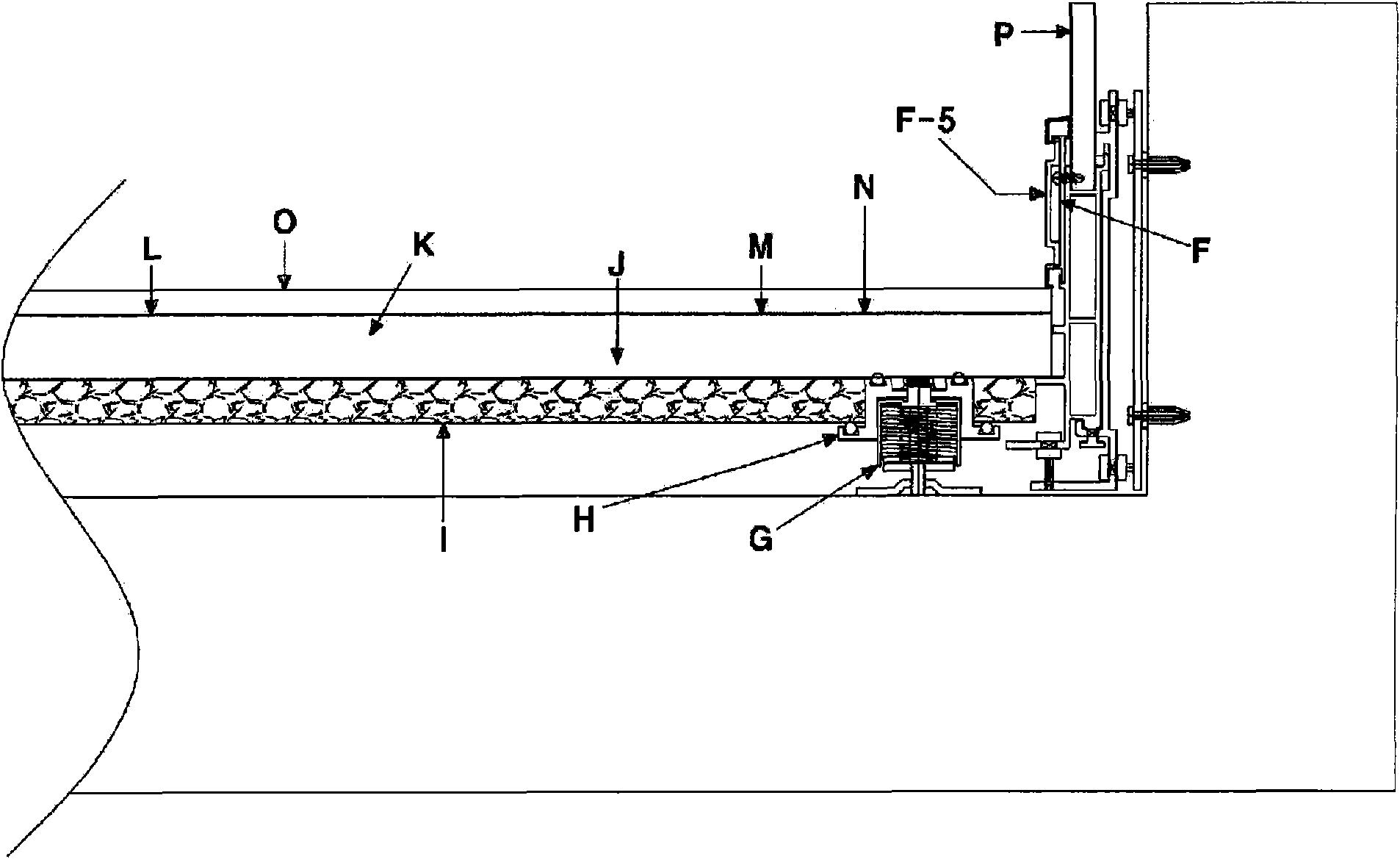

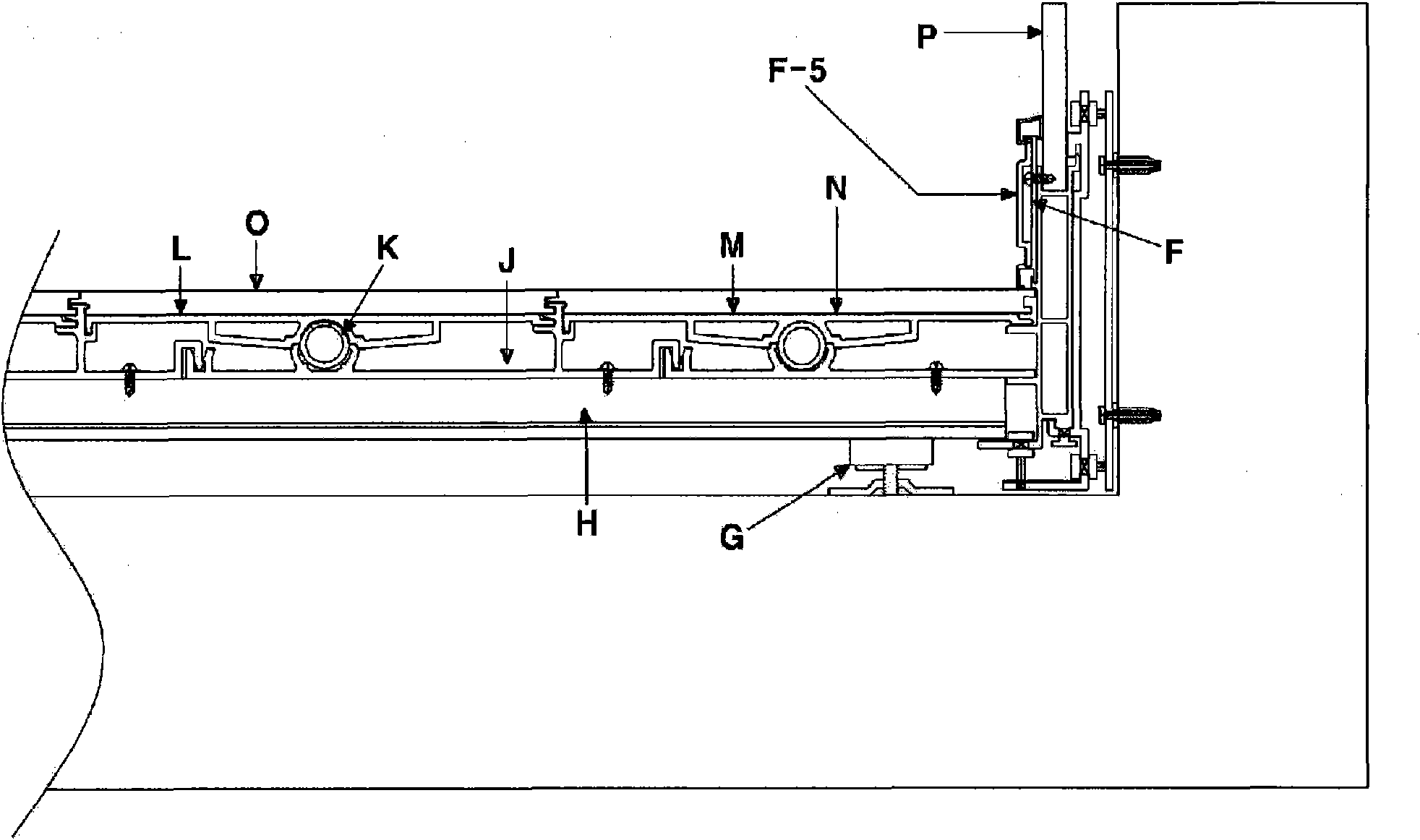

[0046] refer to figure 1 , figure 2 and image 3The configuration of the present invention will be described. A plurality of brackets A are fixed on each wall of the room at positions spaced apart from each other at regular intervals. An auxiliary bracket C is mounted on the front surface of each bracket A. An edge frame D is provided on the front surfaces of the auxiliary brackets C provided on each wall. A plasterboard P is provided on the upper end of the edge frame D. As shown in FIG. The horizontal beam H is supported on the front support stop D-6 of the edge frame D of the opposite wall. The sound and heat insulation board I is arranged on the upper surface of the lower support stopper H-3 of the horizontal beam frame H. Shock absorbers G are disposed below the horizontal beams H at positions spaced apart from each other at regular i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com