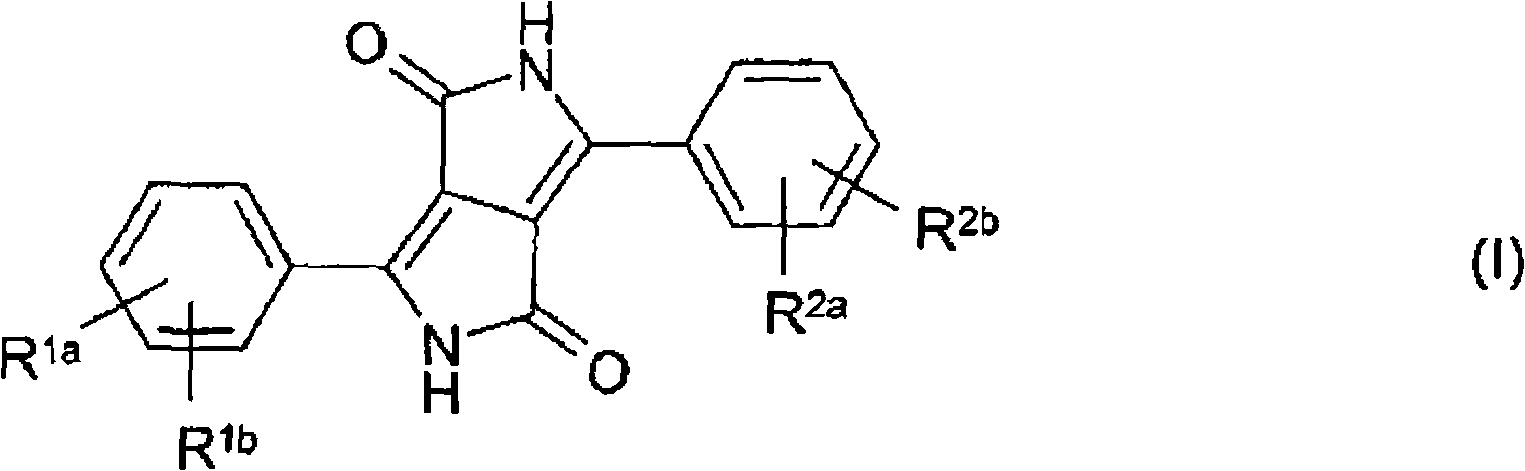

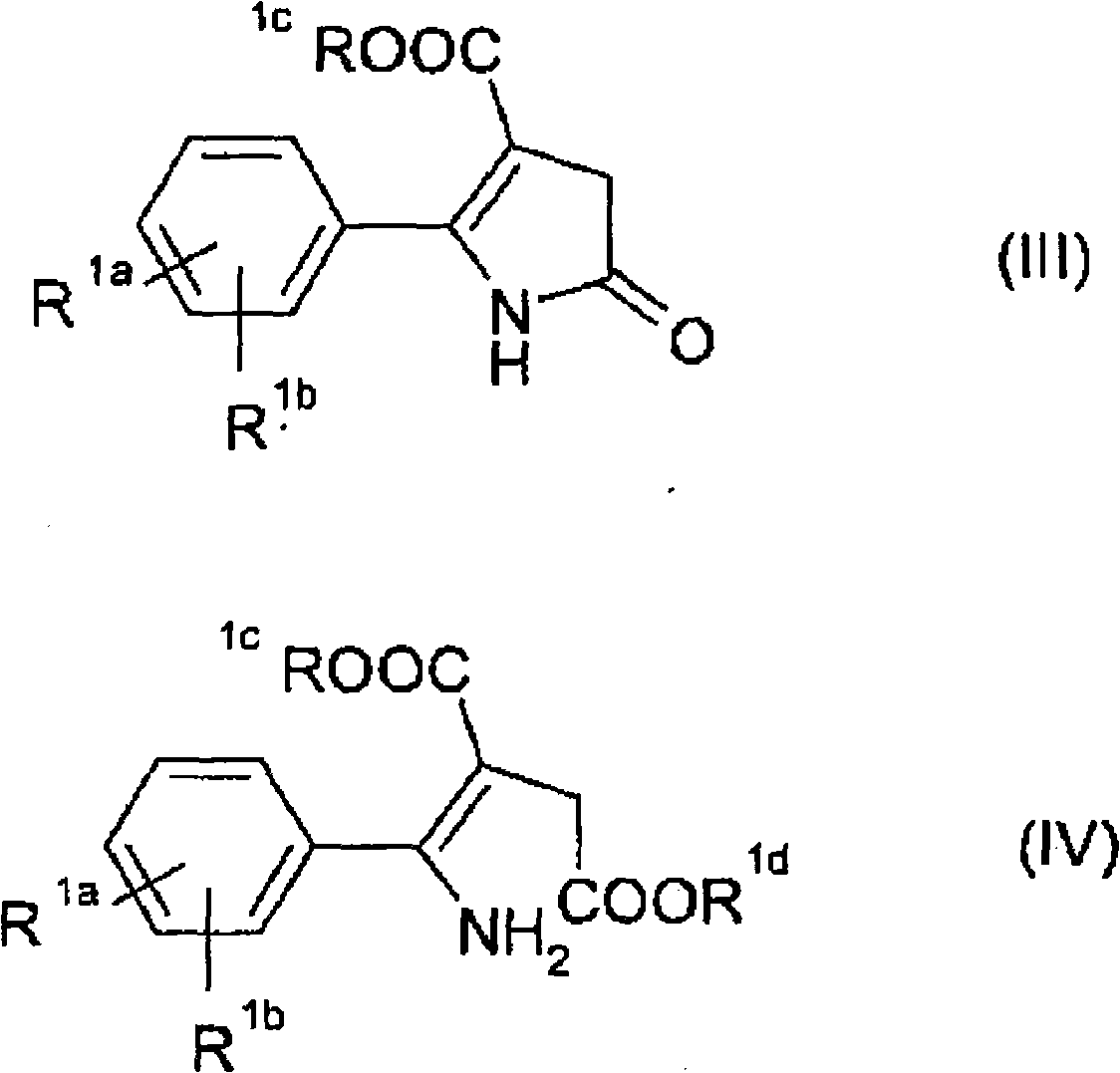

Method for directly producing fine-particle diketopyrrolopyrrol pigments

A technology of diketopyrrolopyrrole and pigments, applied in the direction of diketopyrrolopyrrole dyes, pigment pastes, chemical instruments and methods, etc., which can solve the problems that pigments do not always meet all the requirements of the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The pigment was prepared analogously to Comparative Example 1, but in which the disodium salt of the pigment was converted into a pigment by suspending the hot disodium salt at 80° C. liquid hydrolysis. After separation and washing with methanol and water, a pigment was obtained which had a maximum value of the frequency distribution (distribution pattern) of crystalline particles at 79 nm and a half width of the frequency distribution of 58 nm. The BET surface area of the pigment is 130m 2 / g.

Embodiment 2

[0084] A pigment was prepared analogously to Example 1, in which 1.8 parts of pigment dispersant (VI) were dispersed in water. After separation and washing with methanol and water, a pigment was obtained which had a maximum value of the frequency distribution (distribution pattern) of crystalline particles at 110 nm and a half width of the frequency distribution of 63 nm. The BET surface area of the pigment is 100m 2 / g.

Embodiment 3

[0086] A pigment was prepared analogously to Example 1, in which 3.7 parts of pigment dispersant (VII) were dispersed in water.

[0087]

[0088] After separation and washing with methanol and water, a pigment was obtained which had a maximum value of the frequency distribution (distribution pattern) of crystalline particles of 100 nm and a half width of the frequency distribution of 79 nm. The BET surface area of the pigment is 107m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Bet surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com