Direct-plug water-sealed connector component, plug thereof and socket thereof

A technology for connector assemblies and pin contacts, which is applied to the components, connections, and two-component connection devices of connecting devices, etc. The connector cannot adapt to other problems, so as to achieve the effect of reducing processing accuracy, high processing and assembly efficiency, and strong sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

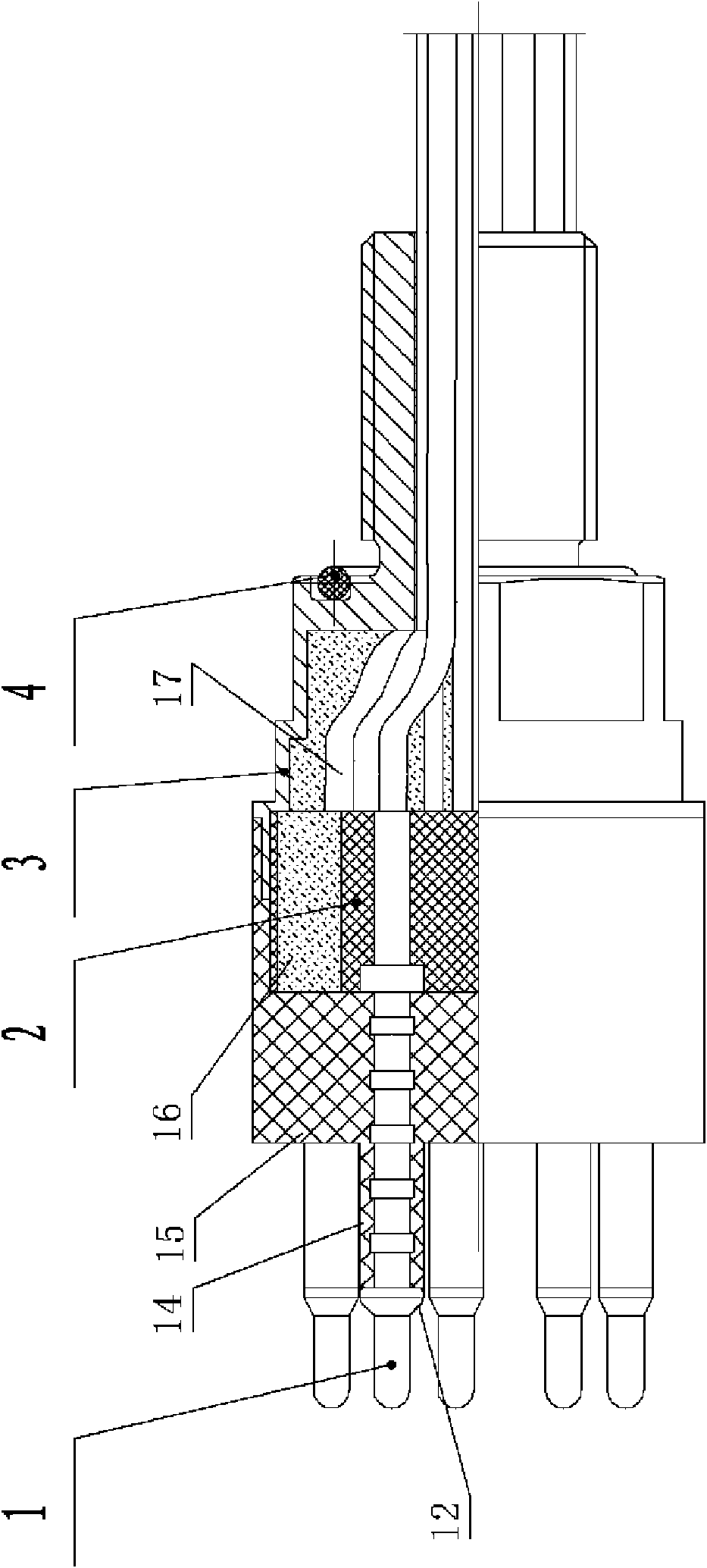

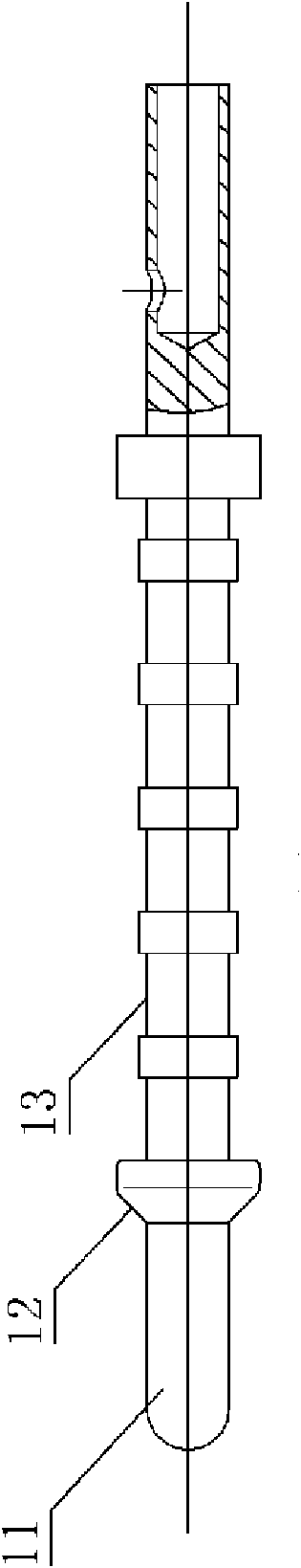

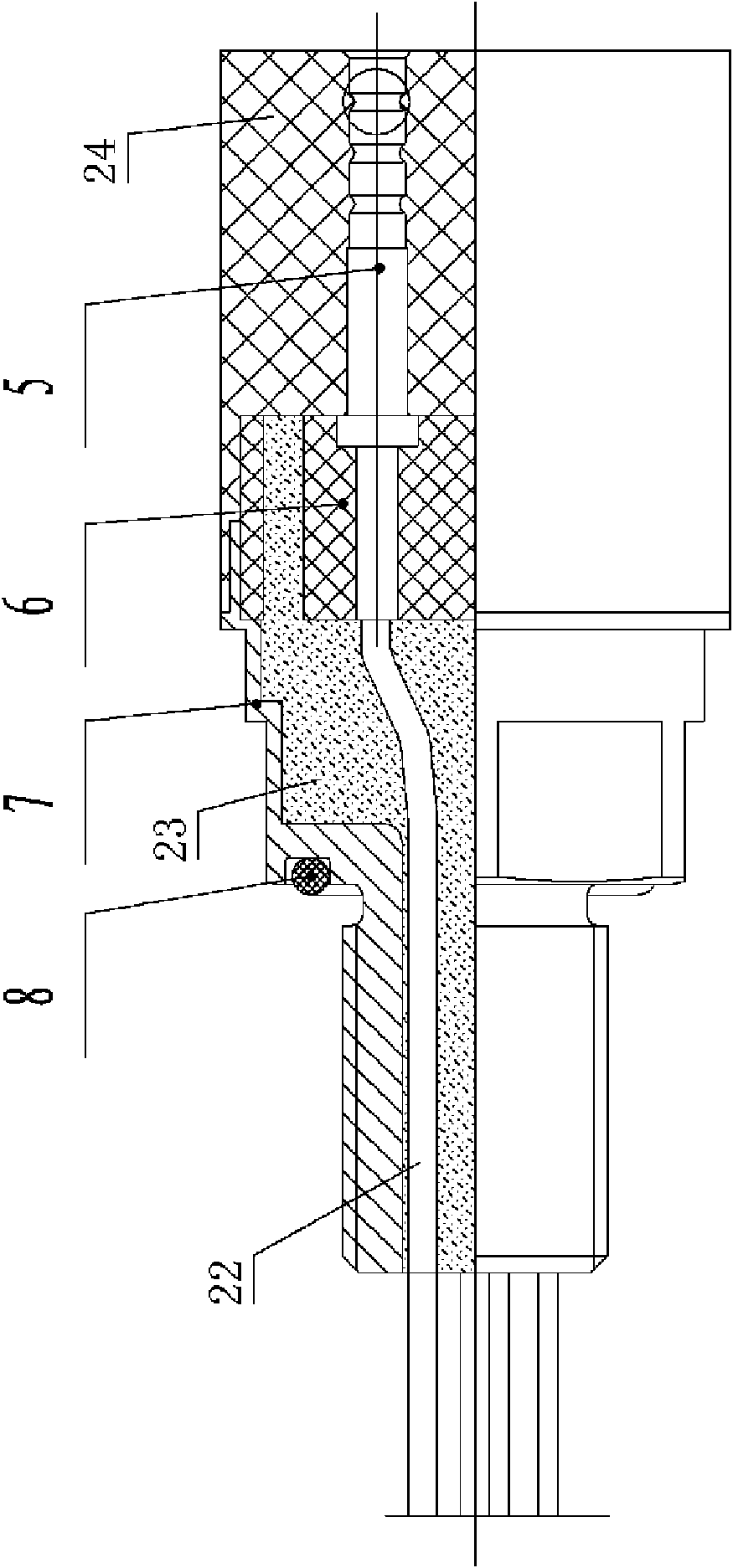

[0021] figure 1 , figure 2 The straight-plug watertight connector plug shown includes a plug housing 3 and a plug insulator 2 assembled together, and a set of pin contacts 1 are axially pierced on the plug insulator 2 , and the front end of the plug insulator 2 and the The peripheral wall is vulcanized and coated with a plug vulcanized body 15. The rear end of the plug vulcanized body 15 extends to seal and covers the front end of the plug housing 3. The part of the external leakage plug vulcanization body 15 of the pin contact forms the pin insertion section, and the part of each pin insertion section close to the plug vulcanization body is covered by the corresponding vulcanization protrusion extending from the front end of the vulcanization body to form vulcanization. The mating section 14, the part of each pin mating section at the front end of the vulcanized mating section 14 is the bare mating section 11, the diameter of the bare mating section 11 is smaller than the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com