Process wall for glue spreading development equipment

A technology of gluing and development and process wall, which is applied to the photoplate making process of pattern surface, optical mechanical equipment, photography, etc., can solve the problems of limited transmission angle, slow transmission speed, inconvenient transmission, etc., and achieve the improvement of effective utilization rate, The effect of reducing work stations and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

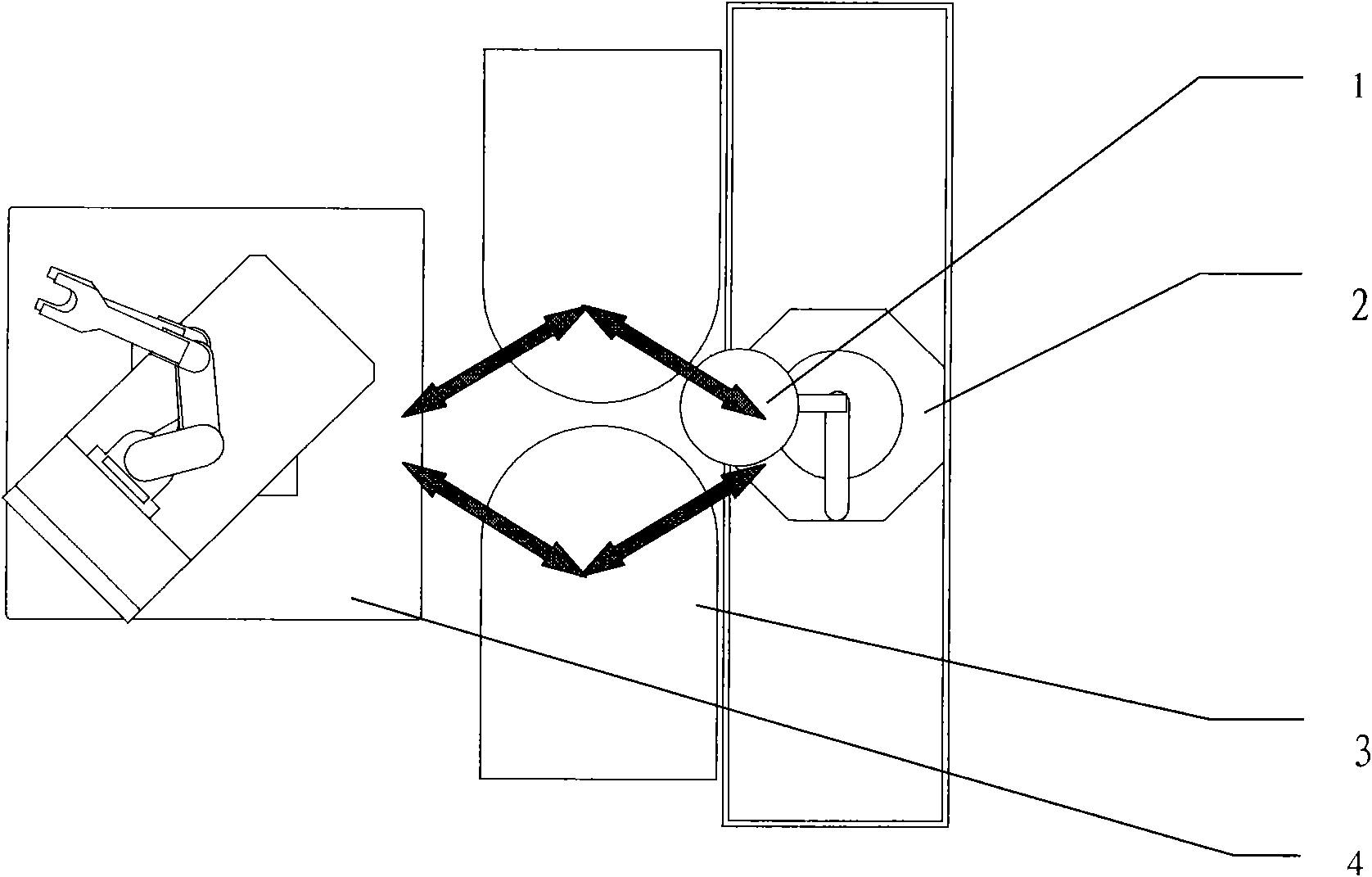

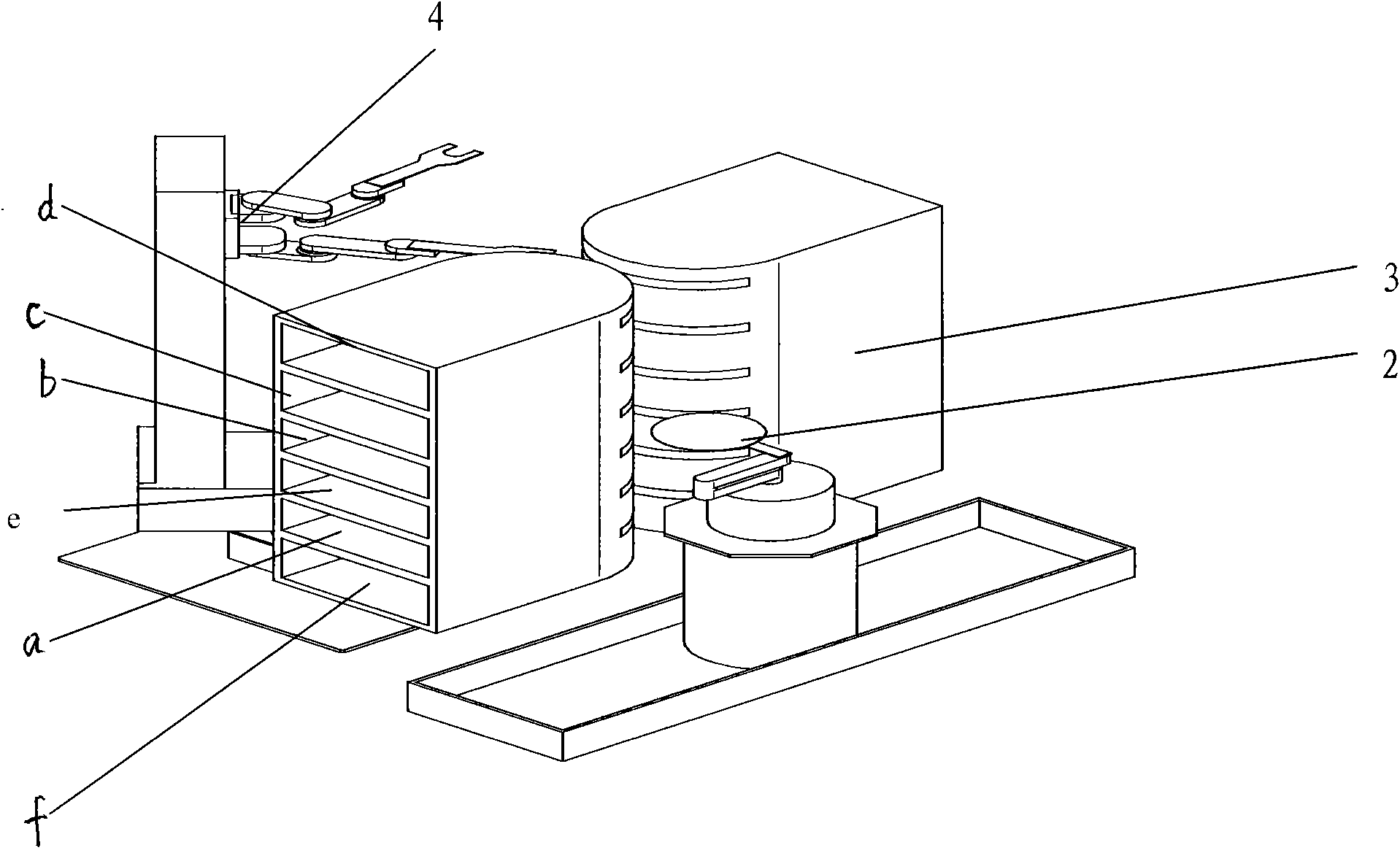

[0020] Embodiment: This example is described by taking a single process wall mode as an example. Such as figure 2 As shown, the process wall 3 is two walls with the same shape and structure, and the process units are arranged parallel and side by side. Each unit of the process wall has a wafer import and export port, and the wafer import and export port is arc-shaped transparent type structure; the arc-shaped inlet and outlet ends of the two walls are placed opposite to each other. The process robot 4 and the box station robot 2 are located on both sides of the wafer inlet and outlet of the process wall 3, and can take out or put wafers in the process wall 3 at the same time.

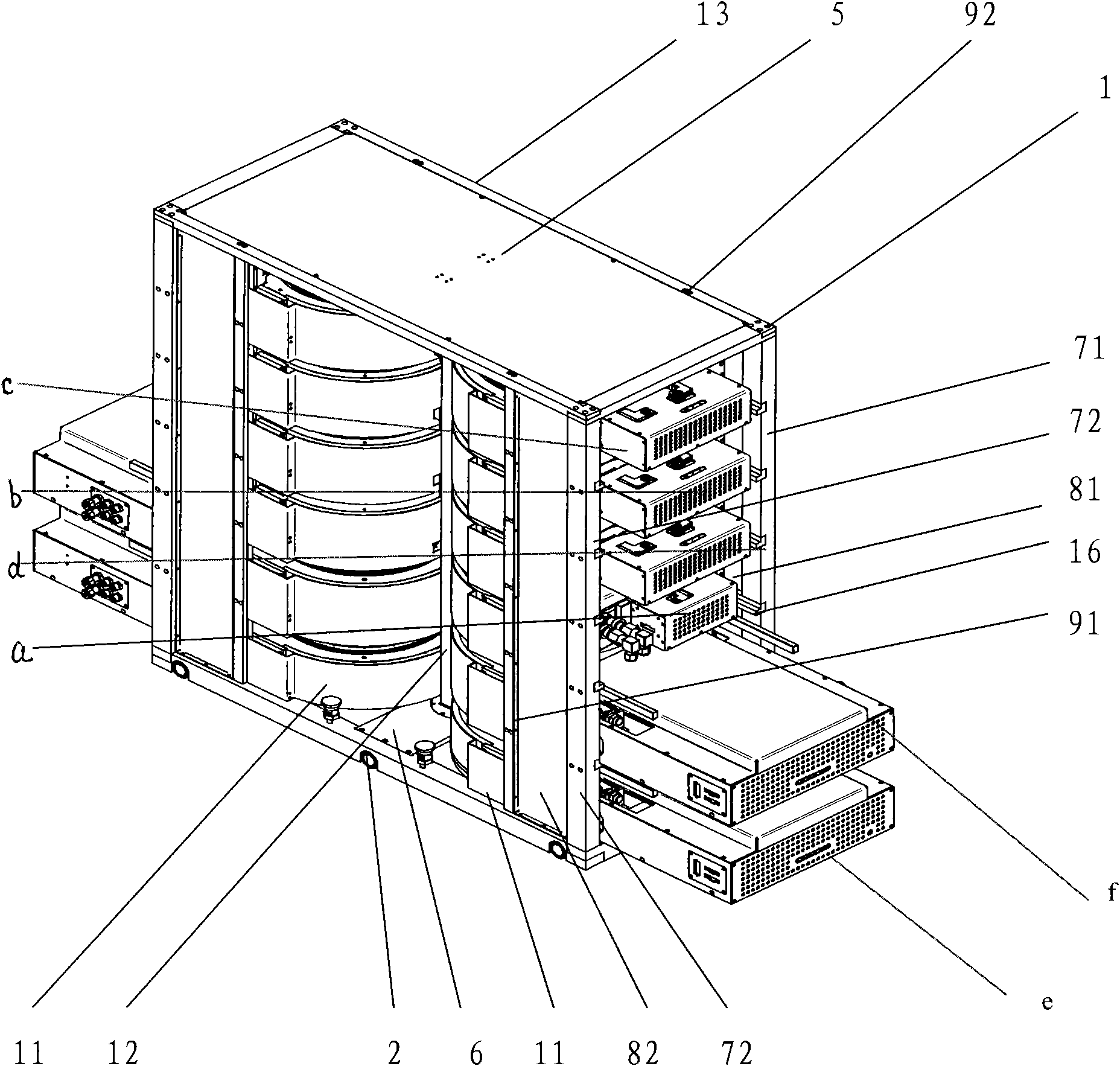

[0021] In order to facilitate the installation of the process wall in the frame of the complete equipment, the process wall of the present invention is installed in the frame of the process wall. The specific structure is as follows image 3 As shown: the frame of the process wall in this example is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com