Waterborne polyurethane resin and preparation method of dipping sizing agent for synthetic leather base material

A water-based polyurethane and synthetic leather base material technology, which is applied in textiles, papermaking, fiber treatment, etc., to achieve good tensile strength, good softness and resilience, and reduce the use and emission of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

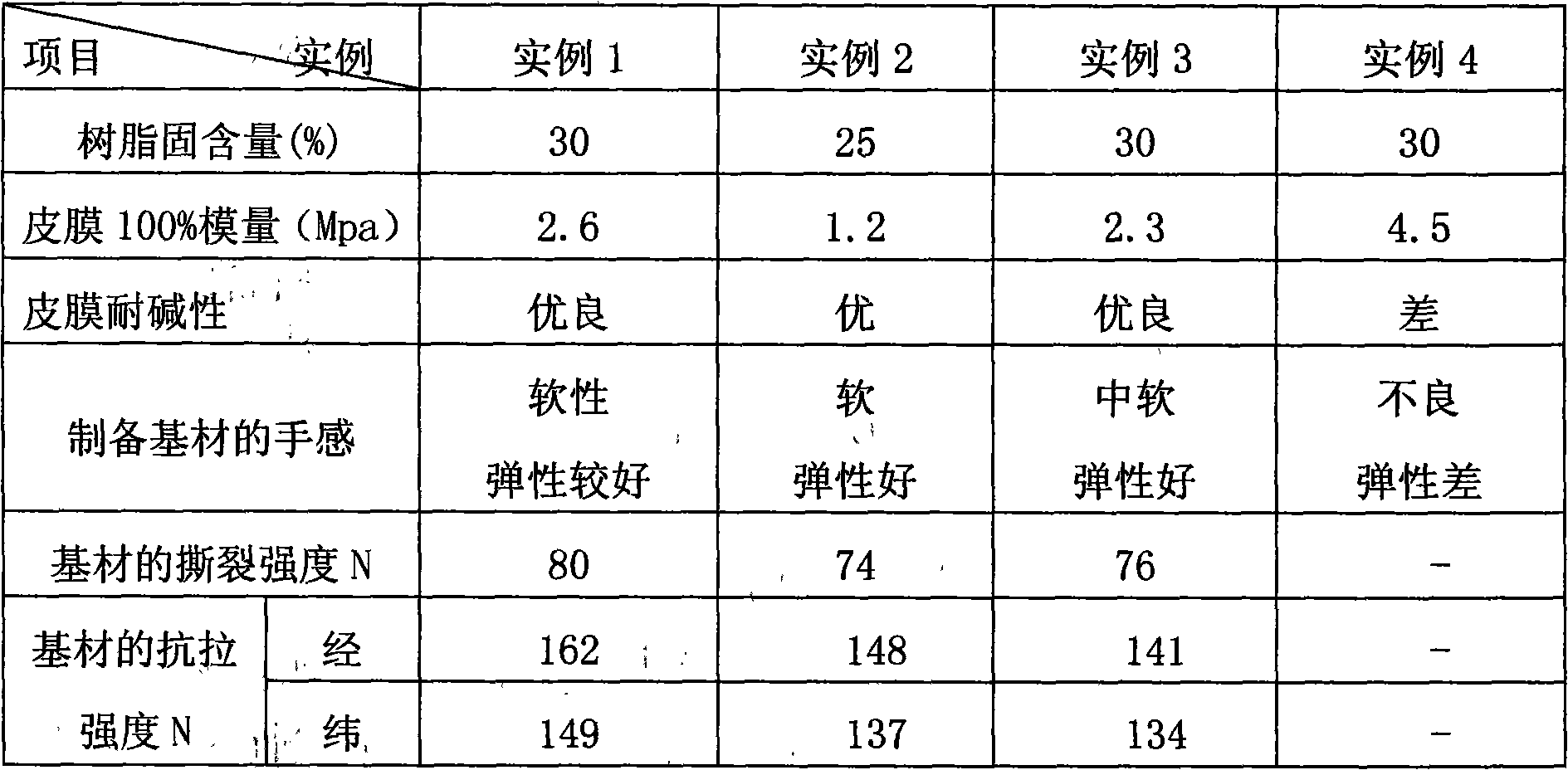

Examples

Embodiment 1

[0033] The first step is to prepare the prepolymer: isophorone diisocyanate 100g, polytetrahydrofuran glycol ether 202g, polycaprolactone glycol ester 81.2g, dimethylol propionic acid 16.8g;

[0034] The second step is to prepare water-based polyurethane resin: add triethylamine to the prepolymer and emulsify it in water, and the solid content after emulsification is 30%;

[0035] The third step is to obtain a stable dipping water-based polyurethane resin slurry: add Wet-245: 8.9g, Rheolate-255: 11.2g, and A-321: 5.6g to the water-based polyurethane resin.

[0036] The specific technological process of the impregnated slurry for the synthetic leather base material of the present embodiment is as follows:

[0037] 1. Processing of prepolymer: Put 100g of isophorone diisocyanate, 202g of polytetrahydrofuran glycol ether, and 81.2g of polycaprolactone into a reaction kettle equipped with mechanical stirring and temperature controller, stir, and heat up 16.8 grams of dimethylolpr...

Embodiment 2

[0041] The first step is to prepare the prepolymer: 100g of isophorone diisocyanate, 212.6g of polytetrahydrofuran glycol ether, 148g of polyoxypropylene glycol ether, and 19.7g of dimethylol butyric acid;

[0042] The second step is to prepare water-based polyurethane resin: after adding triethylamine to the prepolymer at 40°C, it is emulsified in water, and the solid content after emulsification is 25%;

[0043] The third step is to obtain a stable dipping water-based polyurethane resin slurry: add Wet-260: 19g, Rheolate-278: 28.5g, and A-321: 5.7g to the water-based polyurethane resin.

[0044] The specific technological process of the impregnated slurry for the synthetic leather base material of the present embodiment is as follows:

[0045] 1. Processing of prepolymer: Put 100g of isophorone diisocyanate, 212.6g of polytetrahydrofuran glycol ether, and 148g of polyoxypropylene glycol ether into a reaction kettle equipped with mechanical stirring and temperature controller...

Embodiment 3

[0049] The difference between the preparation method of a kind of synthetic leather substrate dipping slurry of the present example and embodiment 1 is:

[0050] The first step is to prepare the prepolymer: diphenylmethane 4.4-diisocyanate 100g, polyoxypropylene glycol ether 190.6g, polyneopentyl glycol adipate 63.5g, dimethylol propionic acid 15.9g;

[0051] The second step is to prepare water-based polyurethane resin: add triethylamine to the prepolymer at 35°C to emulsify it in water, and the solid content after emulsification is 30%;

[0052] The third step is to obtain a stable dipping water-based polyurethane resin slurry: add Wet-270: 13.2g, TRM203 12.5g, AMP-95: 6.4g to the water-based polyurethane resin.

[0053] The specific technological process of the impregnated slurry for the synthetic leather base material of the present embodiment is as follows:

[0054] 1. Processing of prepolymer: put 100g of diphenylmethane 4.4-diisocyanate, 190.6g of polyoxypropylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com