Biomass feed divider with changeable trough obliquity and vibration frequency and amplitude

A technology of vibration frequency and material distribution device, applied in the field of biomass power generation feeding and conveying, can solve the problems of reducing the strength and rigidity of the screw shaft, destroying the rotation balance, reducing the service life of the equipment, etc. The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

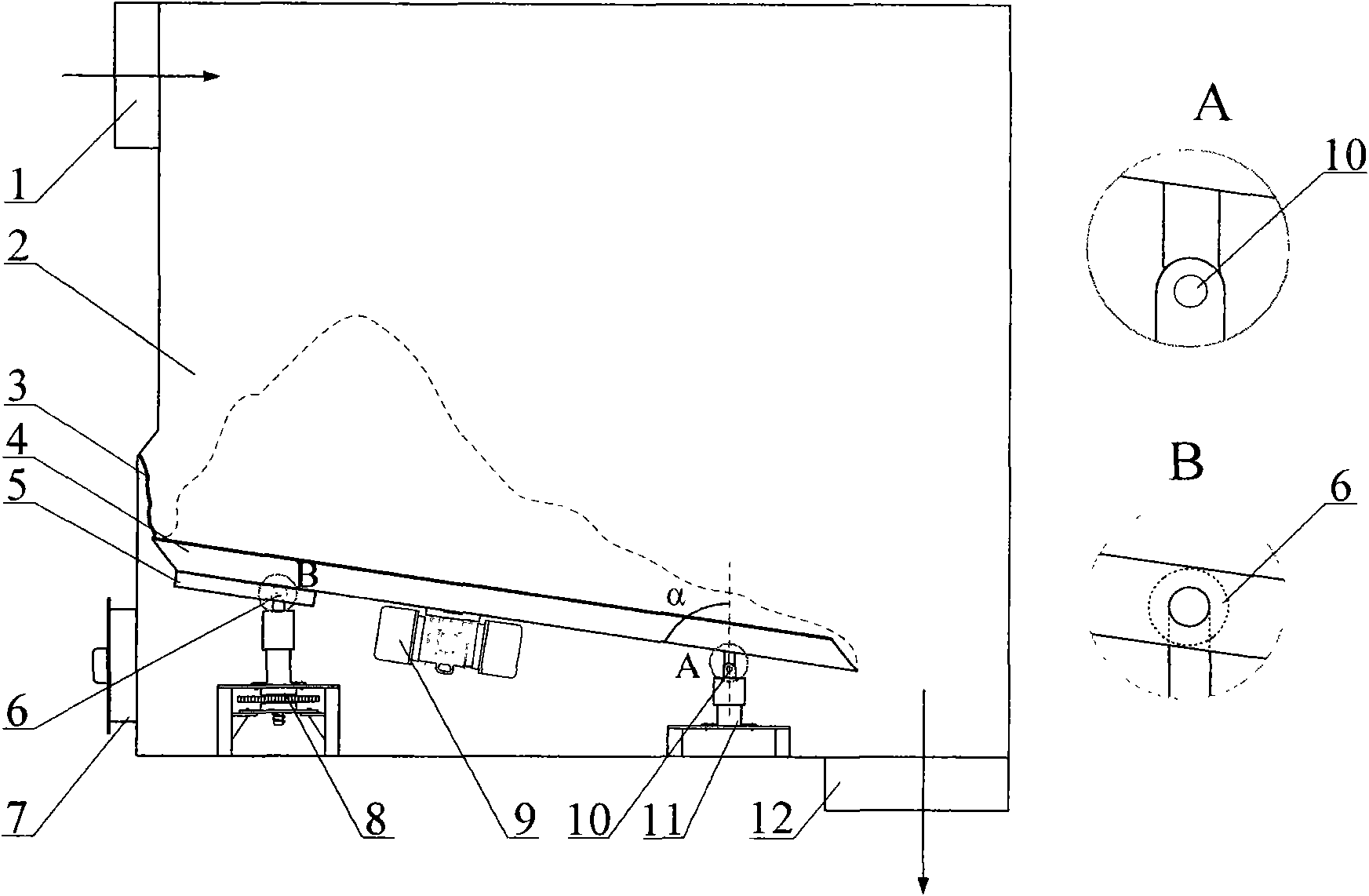

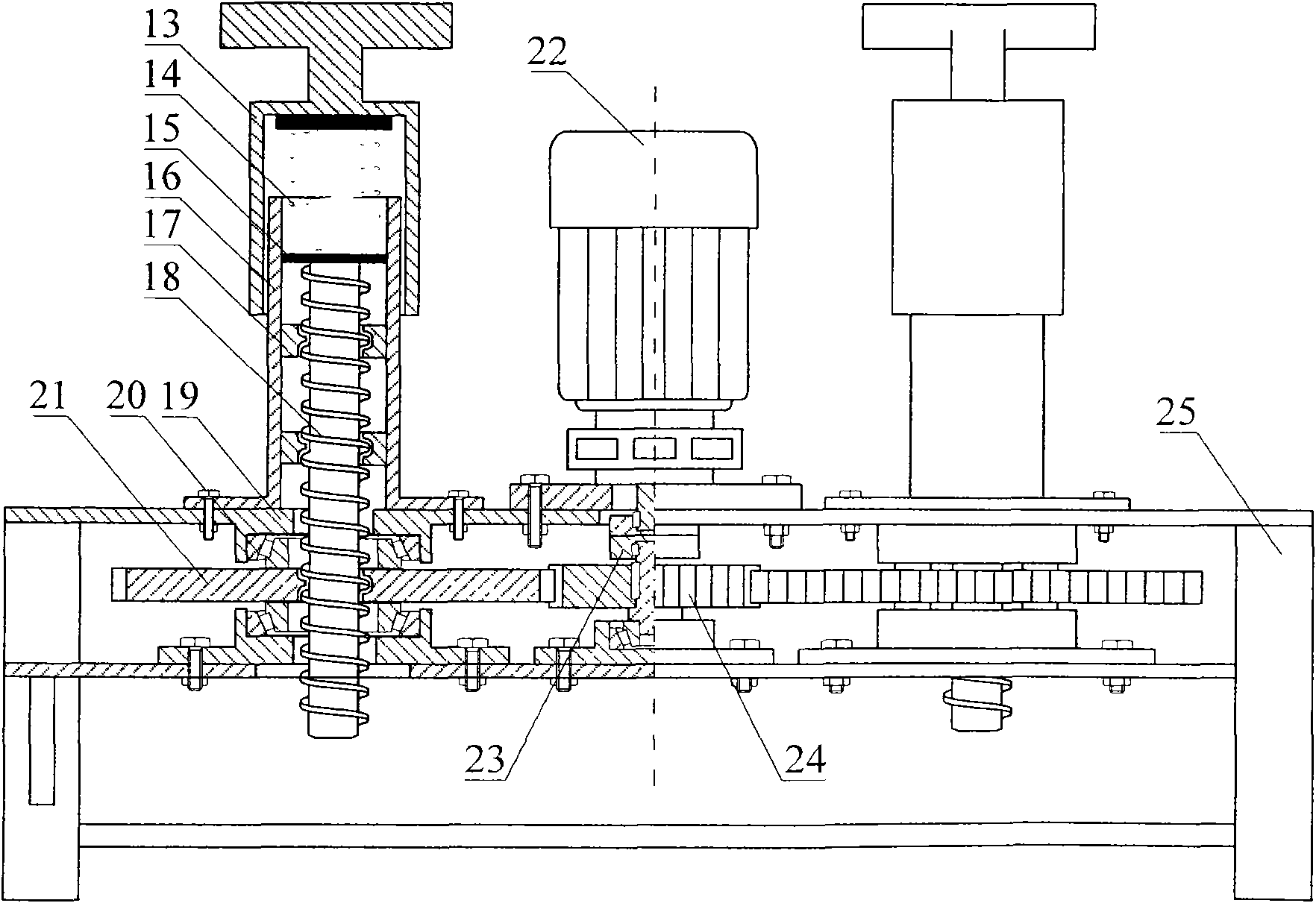

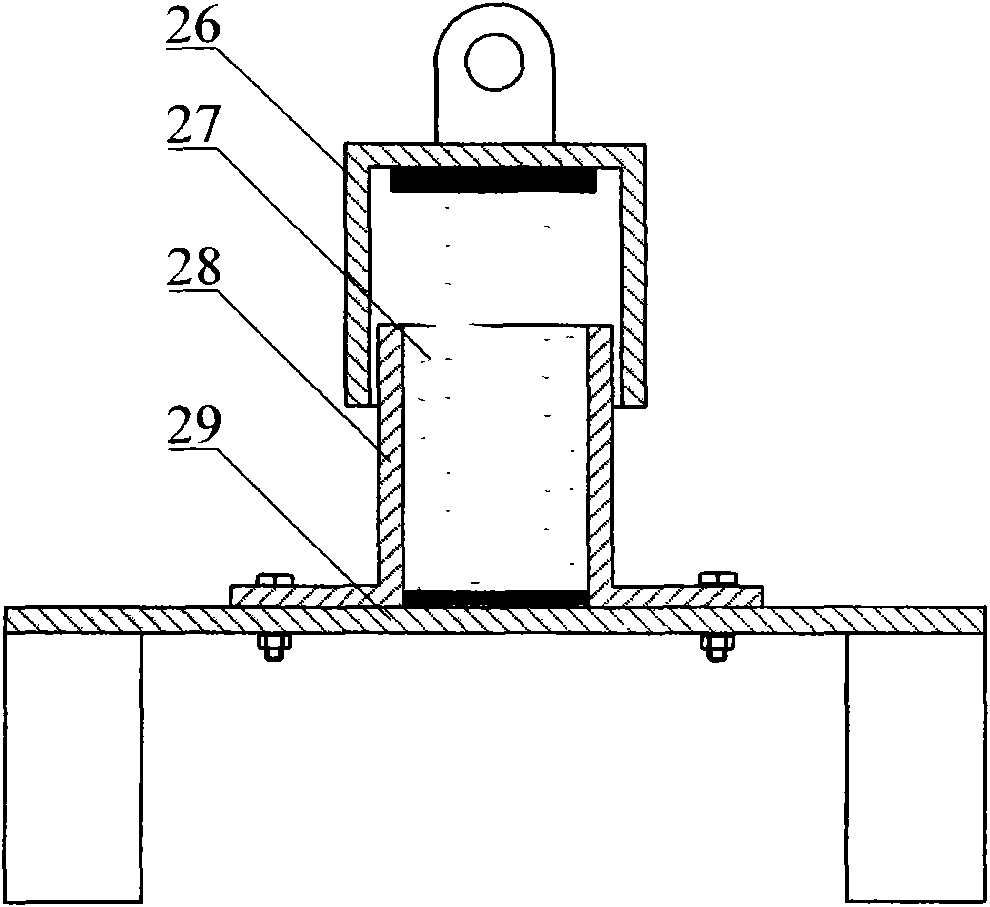

[0032] A biomass distributing device capable of changing the inclination angle, vibration frequency and amplitude of the trough of the present invention is mainly composed of a trough body, a vibration mechanism, a lifting mechanism, a spring support mechanism and an auxiliary mechanism, wherein the trough body includes a trough body 4. Orientation track 5, rolling bearing 6; vibration mechanism includes vibration motor 11; lifting mechanism includes outer sleeve 13, spring 14, slider 15, inner cylinder 16, nut 17, lifting screw 18, tapered bearing 19, bearing seat 20 , large gear 21, vertical frequency conversion speed reducer 22, coupling 23, pinion 24, bracket 25; spring support mechanism includes outer sleeve 26, spring 27, inner tube 28, bracket 29; auxiliary mechanism includes silo Inlet 1, intermediate silo 2, canvas 3, round screw 10, silo outlet 12.

[0033]Before the distributor works, adjust the inclination angle α of the trough 4 according to the characteristics of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com