Special grinding machine for ground finish of crystal silicon square billet

A grinding and special grinding machine technology, applied in machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve problems such as low production efficiency, poor processing accuracy, and complex processes. Achieve the effect of high production efficiency, good surface quality and improved operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

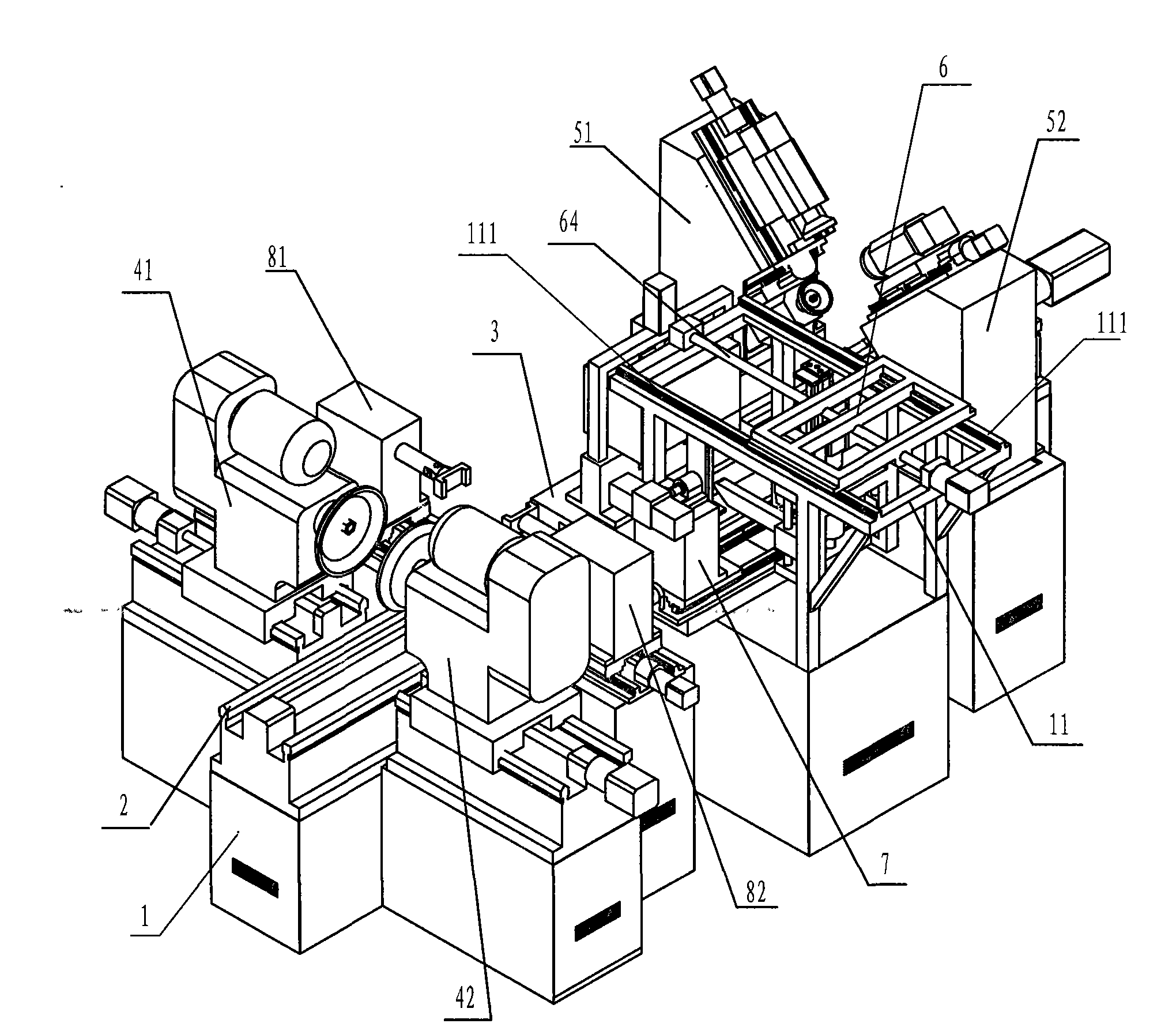

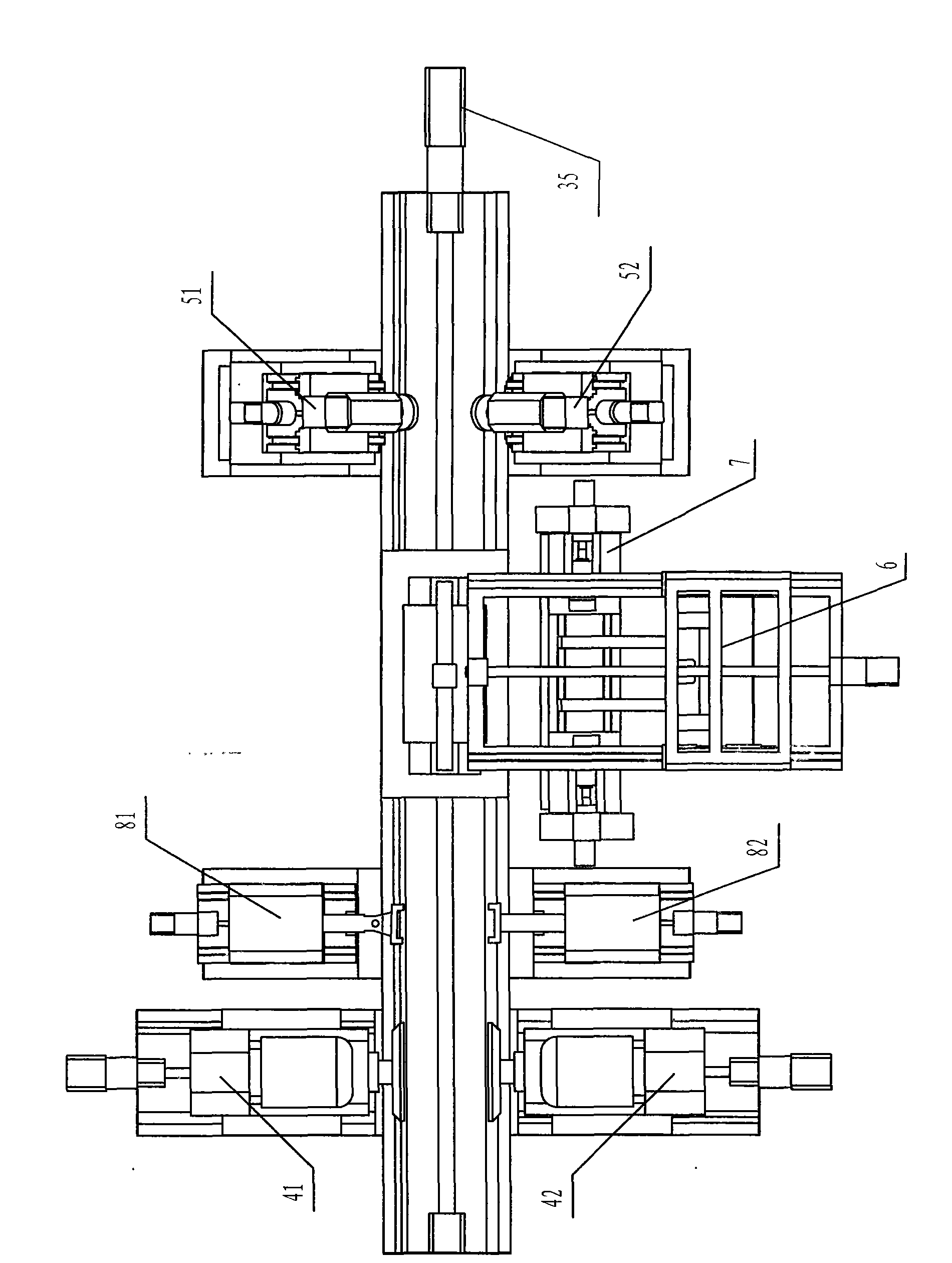

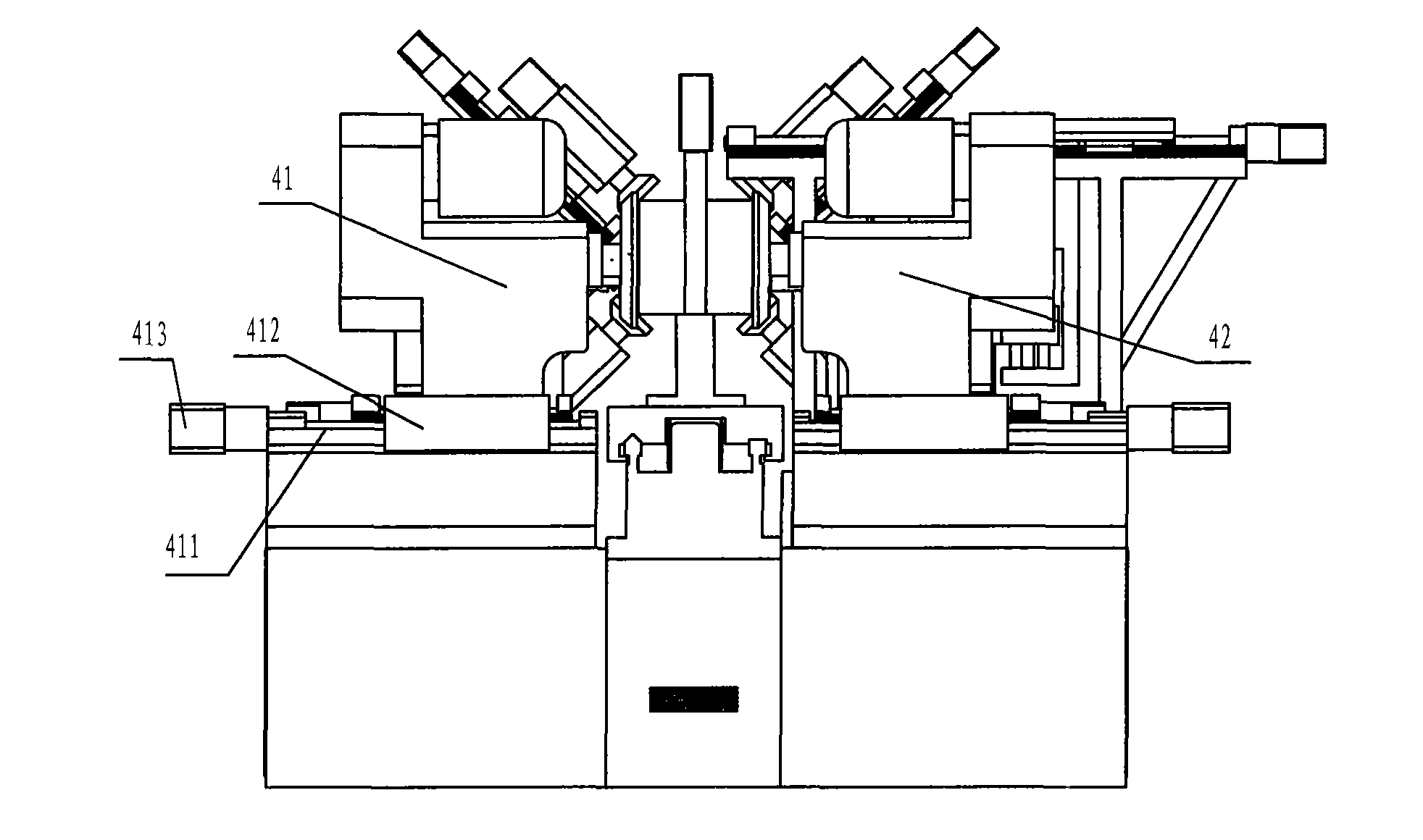

[0034] refer to Figure 1-9

[0035]A special grinding machine for crystalline silicon billet grinding, including a base 1, and the base 1 is provided with:

[0036] The guide rail 2 and the workbench 3 for placing the crystalline silicon billet, the workbench 3 is slidably installed on the guide rail 2, and the workbench 3 is linked with the working motor 35 fixed on the base 1;

[0037] The first side grinding power head 41 and the second side grinding power head 42 are arranged symmetrically on both sides of the guide rail 2 to grind the two sides of the crystalline silicon billet;

[0038] The first chamfering mechanism 51 and the second chamfering mechanism 52 are arranged symmetrically on both sides of the guide rail 2 to chamfer the four corners of the crystalline silicon billet. The upper chamfering bracket 511, the chamfering bracket 511 is symmetrically equipped with an upper chamfering grinding power head 512 and a lower chamfering grinding power head 513 for cham...

Embodiment 2

[0043] refer to Figure 1-5

[0044] The difference between this embodiment and Embodiment 1 is that: the base 1 is provided with a centering slide rail 813, and a centering slide table 814 is slidably installed on the centering slide rail 813. The positioning block 812 is connected with the centering slide 814 through a horizontal shaft 815, and the centering slide 814 is linked with the motor 816 that drives the centering slide 814 to move through the centering feed mechanism , the centering feed mechanism is a screw mechanism; the first positioning block 812 of the first centering mechanism 81 is hinged to the first horizontal shaft 815 .

[0045] The centering mechanism 81, 82 is arranged between the side grinding power head 41, 42 and the chamfering mechanism 51, 52, and the transfer manipulator 6 is arranged in the centering mechanism 81 , 82 and the chamfering mechanism 51,52. The rest is the same.

Embodiment 3

[0047] refer to Figure 8 , 9

[0048] The difference between the present embodiment and the second embodiment is that the turning mechanism also includes a sliding track 713 fixed on the base 1 and a slide table 714 slidably mounted on the sliding track 713 forward and backward. The clamping claw 711 is rotatably arranged on the slide table 714, and the swing cylinder 712 is fixed on the slide table 714; , promote the cylinder 715 that slide table 714 moves back and forth.

[0049] The clamping claw 711 includes a clamping frame 7111 and an upper clamping piece 7112 and a lower clamping piece 7113 connected with the clamping frame 7111; the upper clamping piece 7112 is fixed with an upper nut, so The lower clamping piece 7112 is fixed with a lower nut 7114, and the thread direction of the upper nut and the lower nut 7114 is opposite; the clamping frame 7111 is fixed with the upper and lower nuts Cooperating screw rod 7115, the thread direction of the upper half of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com