Catalyst capable of reducing carbon monoxide content in cigarette smoke, preparation method and application of same

A technology for carbon monoxide and cigarette smoke, applied in the fields of application, tobacco, and tobacco treatment, to achieve the effects of reducing carbon monoxide content, convenient operation, and low metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Carrier meso-Al 2 o 3 Synthesis of -a: 6.078g template agent P123 (EO 20 PO 70 EO 20 ) with 0.060g LaCl 3 Dissolve them together in 25ml of sec-butanol, and add 5.4ml of aluminum sec-butoxide under stirring. After stirring at room temperature for 1 h, the mixture of water and sec-butanol (1.14mlH 2 0 / 10mlsec-butanol) slowly dropwise into it, and the mixture consists of:

[0042] 0.01La 3+ :1.0Al(Bu s O) 3 :0.10EO 20 PO 70 EO 20 :3.0H 2 O:15.5Bu s Oh. The mixture was stirred at 45°C for 48 hours, filtered, dried, and calcined at 500°C for 6h in an air atmosphere to obtain the product, marked as meso-Al 2 o 3 -a. With low temperature N 2 Determination of meso-Al by adsorption-desorption method 2 o 3 - The specific surface of a is 325m 2 / g, the pore volume is 0.93cm 3 / g, the average pore diameter is 7.5nm; with CO 2 Temperature programmed desorption (CO 2 -TPD) method to measure its surface basicity is 0.0369mmol[OH - ] / g; the isoelectric point I...

Embodiment 2

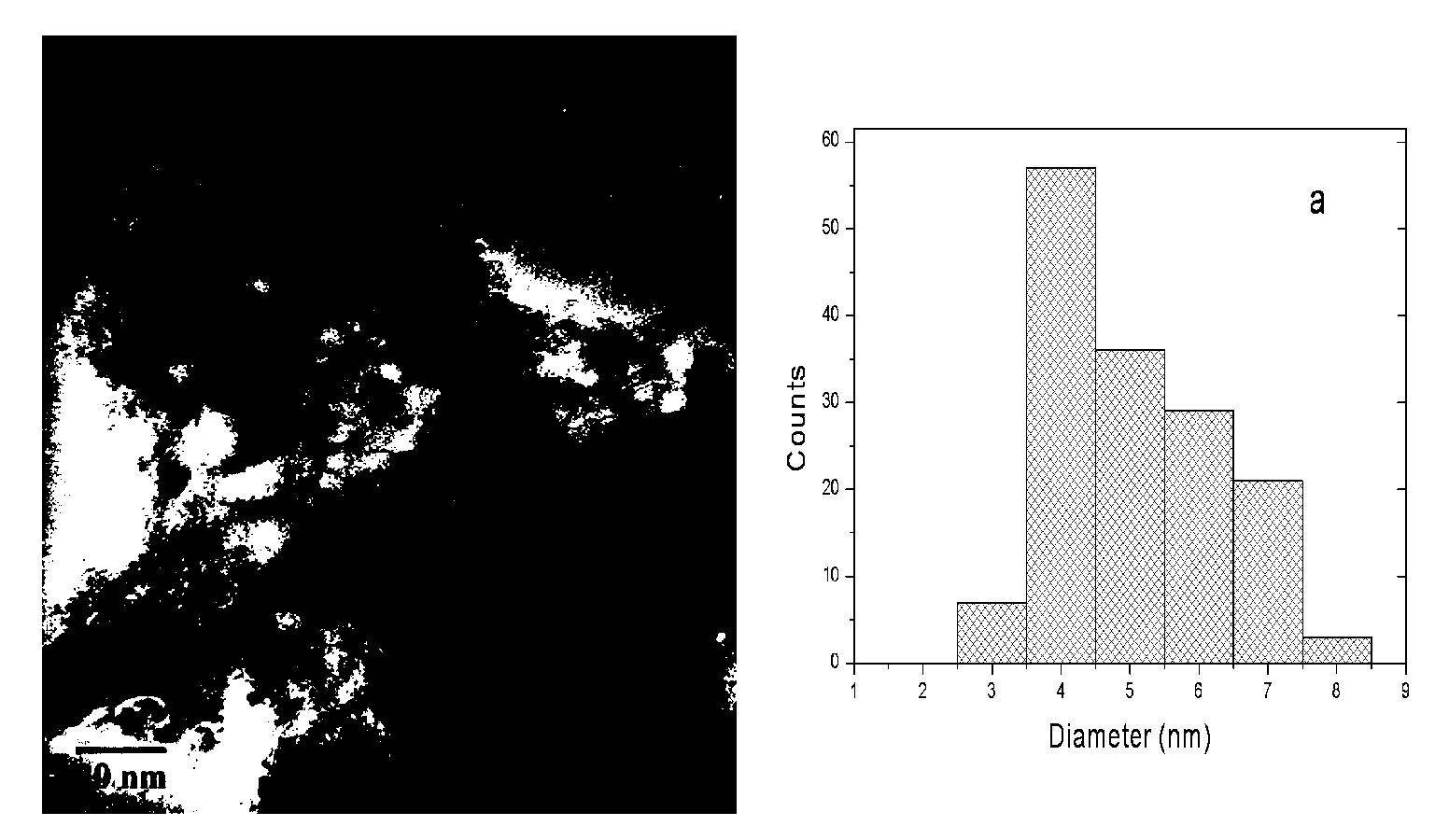

[0046] Deposition-precipitation method (DP) prepares, with the meso-Al prepared in example 1 2 o 3 -a as carrier, with Na 2 CO 3 As precipitant, HAuCl 4 The solution (concentration is 9.71mmol / L) was adjusted to pH=7, under vigorous stirring, 1.0g carrier meso-Al 2 o 3 -a was added to it, reacted for 4h, filtered, washed with hot water (70-80°C) several times, and AgNO 3 (0.10mol / L) detected no Cl - , Dry at 70°C for 10h. Then calcined at 350°C for 1.0h, cooled to room temperature, and then reduced with hydrogen at 300°C for 1.0h to obtain the catalyst Au / meso-Al 2 o 3 -a(DP). With low temperature N 2 Determination of Au / meso-Al by Adsorption-Desorption Method 2 o 3 -a(DP) has a specific surface area of 209m 2 / g, the pore volume is 0.45cm 3 / g, the average pore diameter is 4.7nm; the average size of nano-Au particles on the surface of the carrier is 4.9nm.

[0047] Catalyst Au / meso-Al 2 o 3 -a(DP) tableting and sieving, selecting 40-60 mesh particles and di...

Embodiment 3

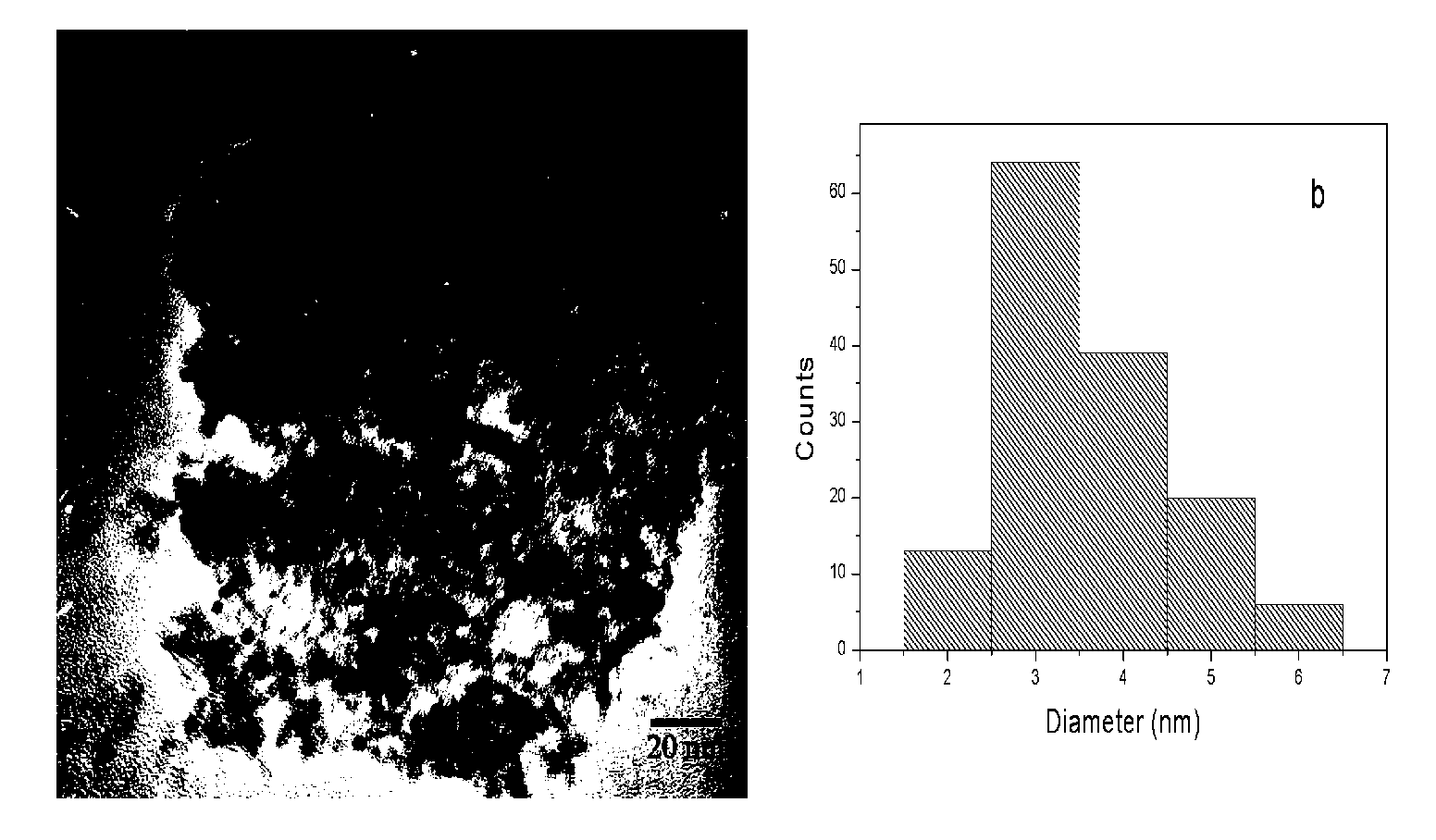

[0049] Prepared by anion exchange method (DAE), using the meso-Al2O3-a prepared in Example 1 as a carrier, mix the HAuCl4 solution with a concentration of 9.71mmol / L and 1.0g carrier evenly, and stir at room temperature for 1.5h. Filter, wash three times with ammonia water (20% V / V), and then wash with water several times until no Cl is detected by AgNO3 (0.10mol / L) - . Dry at 70°C for 10h, calcinate at 350°C for 1.0h, cool to room temperature, and then reduce with hydrogen at 300°C for 1.0h. to obtain the catalyst Au / meso-Al 2 o 3 -a(DAE). With low temperature N 2 Determination of Au / meso-Al by Adsorption-Desorption Method 2 o 3 - The specific surface of a(DAE) is 300m 2 / g, the pore volume is 0.87cm 3 / g, the average pore diameter is 6.7nm; the average size of nano-Au particles on the surface of the carrier is 3.9nm.

[0050]Catalyst Au / meso-Al 2 o 3 -a (DAE) tableting and sieving, select 40-60 mesh particles and disperse them in the cellulose acetate tow to make b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com