Method for preparing sweet potato amylodextrin by acid-alcohol medium

A technology for starch dextrin and sweet potato starch is applied in the field of preparing sweet potato starch dextrin by alcohol medium acid method, which can solve the problems of long reaction time and the like, and achieve the effects of short reaction time, simple and practical process, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

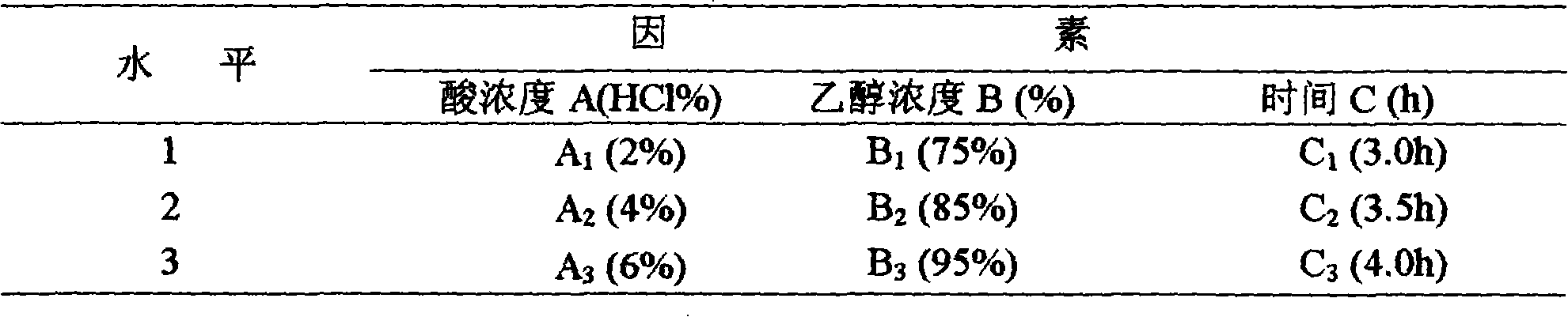

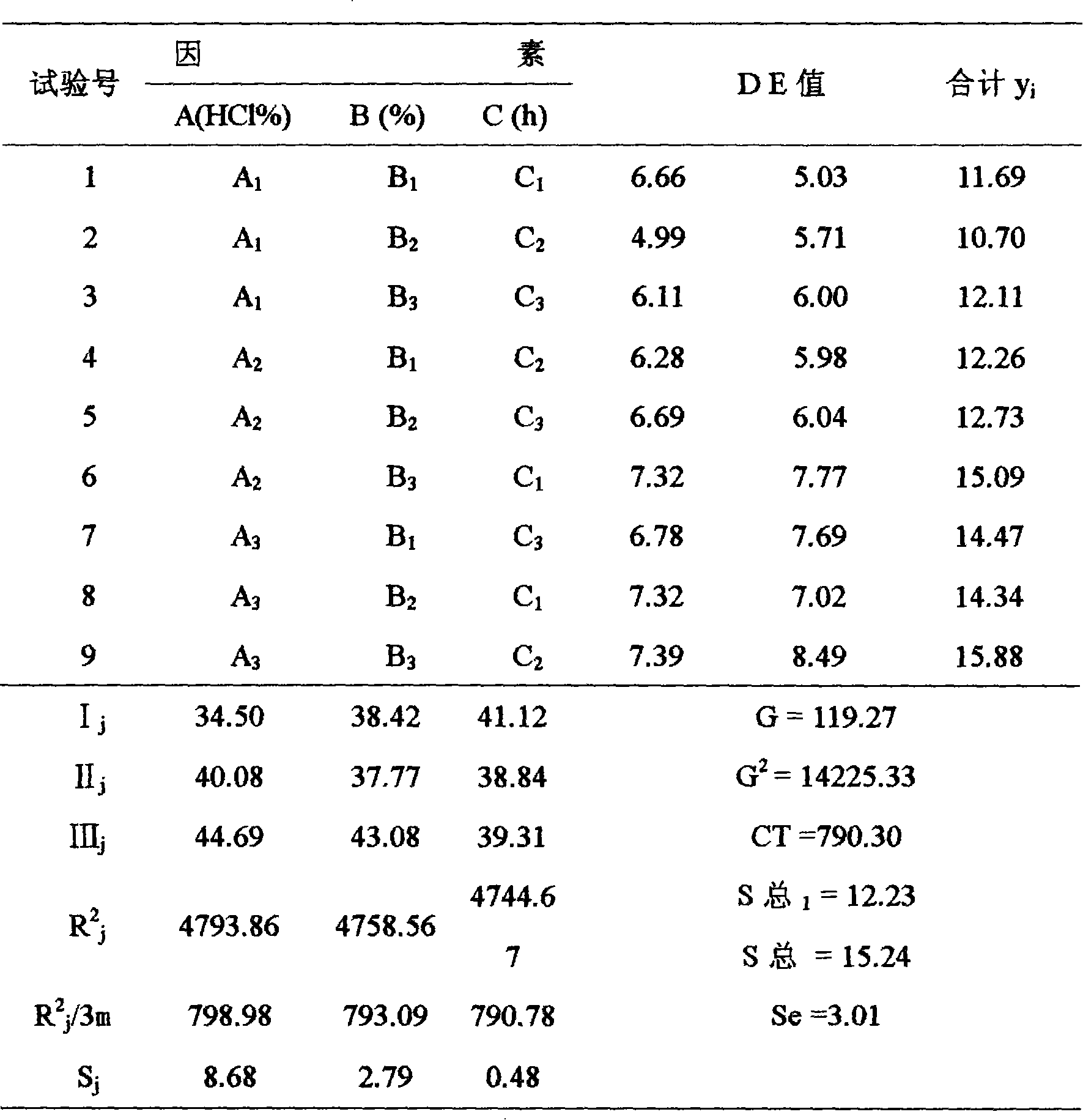

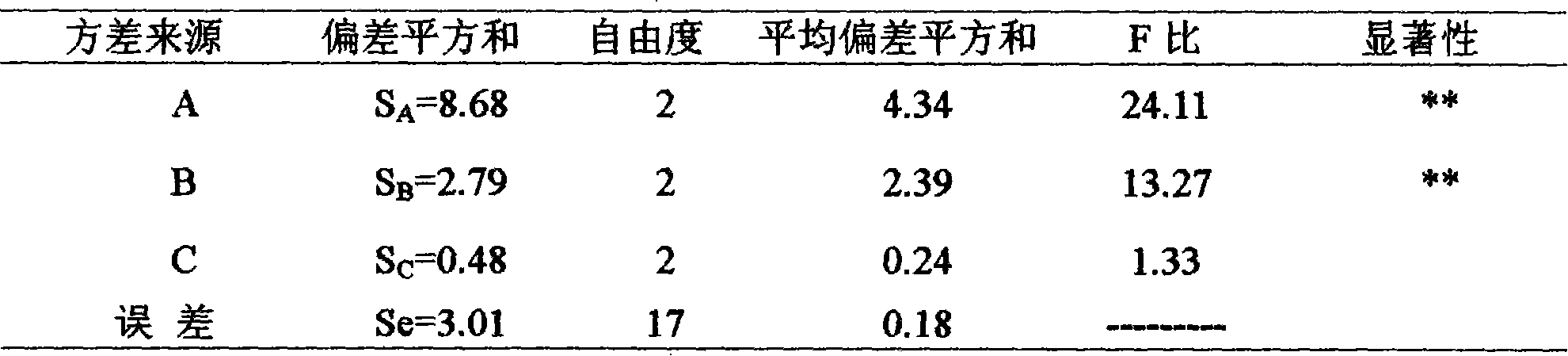

[0025] Sweet potato starch dextrin alcohol medium acid hydrolysis process:

[0026] 13~15 grams of sweet potato starch → put into 75~80ml ethanol solution and hydrolyze with hydrochloric acid with a concentration of 2~6% → heat to the boiling point of 79~81°C, reflux and continuously stir, after hydrolysis, filter and separate starch maltodextrin, disperse in Neutralize to pH=7 with 10% NaOH in distilled water, dehydrate, wash with distilled water 7 times, dehydrate with ethanol 4 times, and dry at 40-50°C for 6 hours to prepare sweet potato starch dextrin.

Embodiment 2

[0028] Determination of water holding capacity of sweet potato starch dextrin:

[0029] The water holding capacity of 10% and 30% starch dextrin aqueous solution samples was determined by centrifugation. The sample was weighed and dispersed in distilled water at 20°C according to the specified concentration, and centrifuged at 7500r / min for 15min. Remove the water from the upper part of the tube and weigh it. The water holding capacity can be calculated by the following formula:

[0030] Water holding capacity = (the amount of water in the dispersed sample - the amount of water removed from the upper part of the centrifuge tube) / the amount of starch dextrin

Embodiment 3

[0032] Determination of hygroscopicity of sweet potato starch dextrin:

[0033] Take about 2.5g of starch dextrin sample, put it in a desiccator, place it at 20°C for 1.5 days at different relative humidity, use sulfuric acid solutions of different concentrations to adjust the humidity of the closed environment, and measure the weight change of starch dextrin sample Hygroscopicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com