Solar cell

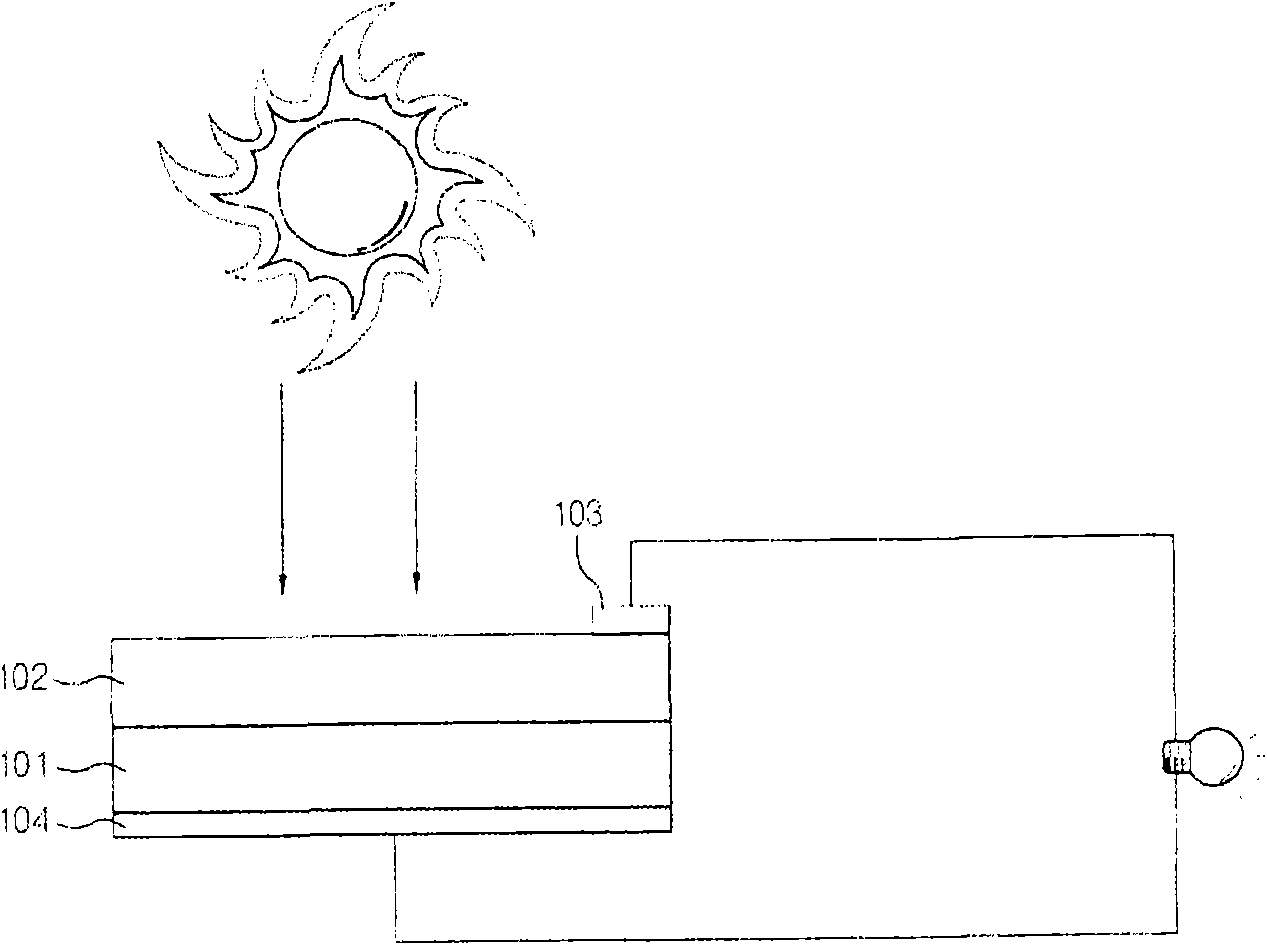

A solar cell, conductive technology, applied in the field of solar cells, can solve problems such as the reduction of sunlight ratio, the reduction of solar cell efficiency, and the limitation of anti-reflection film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

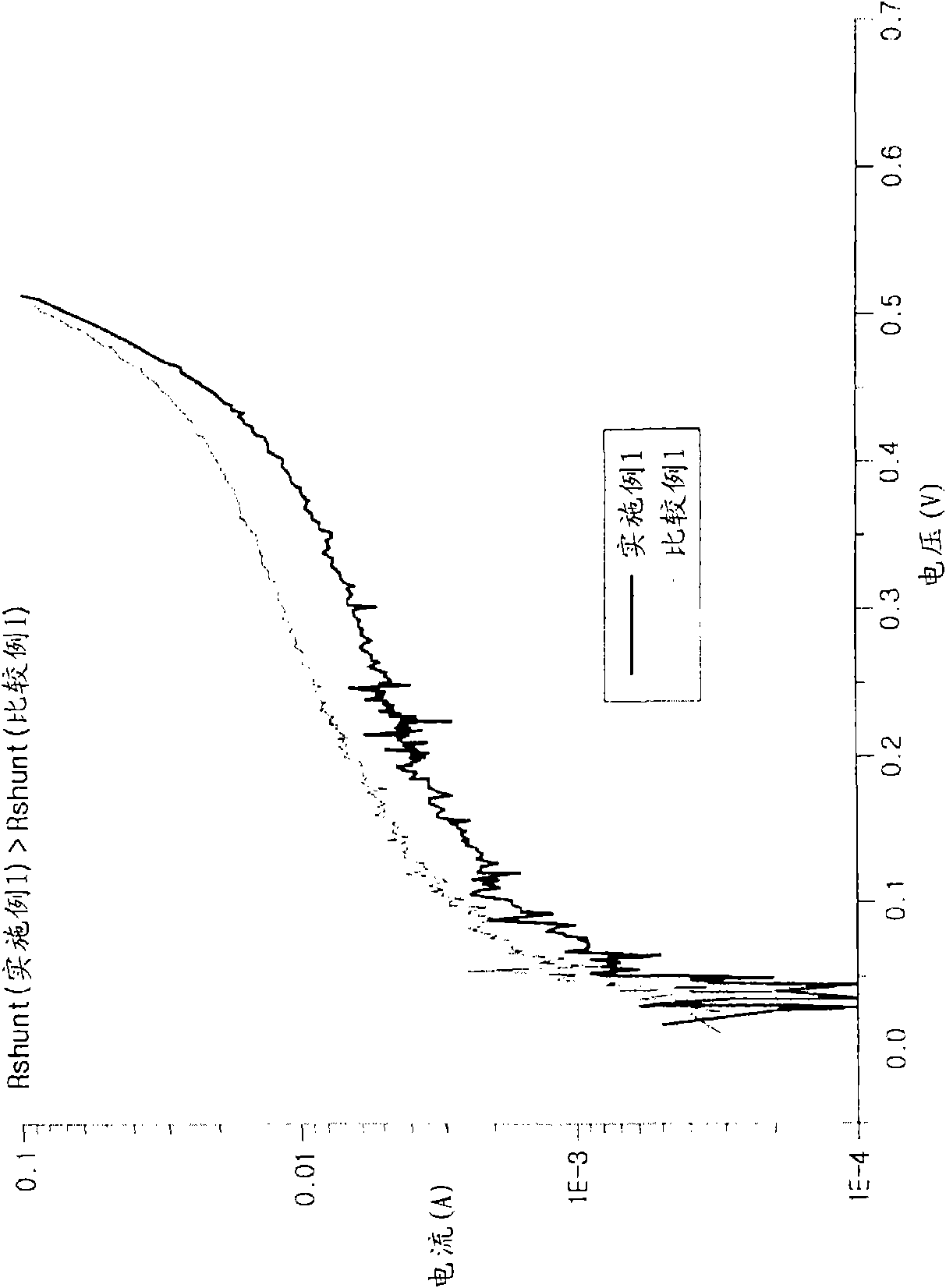

Embodiment 1

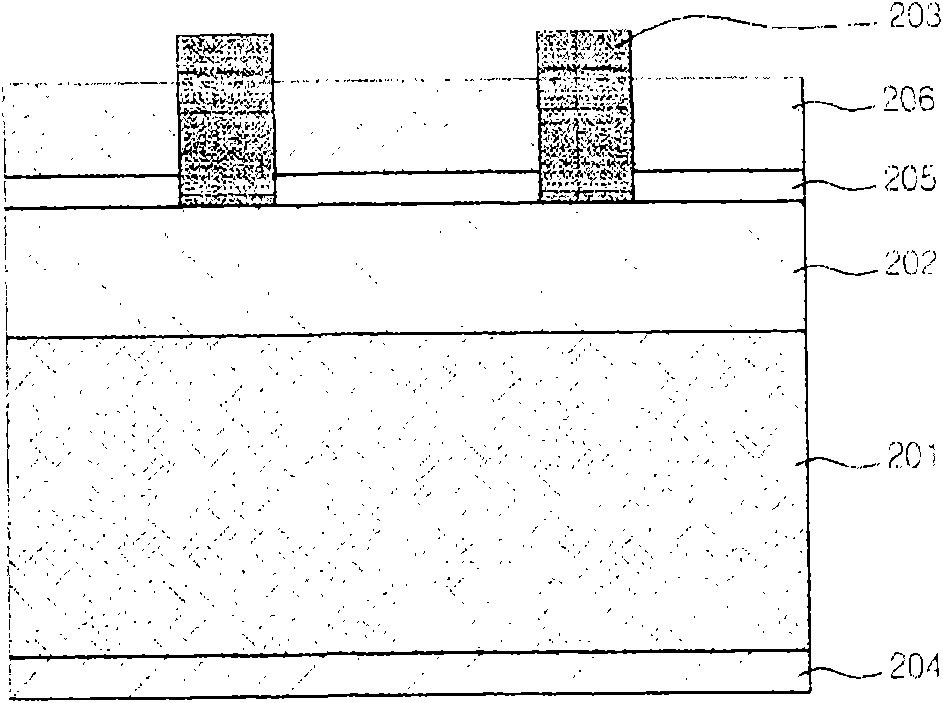

[0035] Made as figure 2 A solar cell with a passivation layer and an anti-reflection film is shown. At this time, as the semiconductor substrate, Cz mono 125×125cm was used 2 A p-type silicon substrate (0.5-2Ω) is used to form an n+ emission layer with 60Ω / sheet. Using Direct High Frequency (13.56MHz) PECVD, a silicon oxynitride passivation layer (refractive index: 1.55, thickness: 30nm) is formed on the above-mentioned emission layer, and a silicon nitride anti-reflection film (refractive index: 30nm) is formed on the above-mentioned passivation layer 1.90, thickness: 64nm). The deposition temperature of the above-mentioned passivation layer and anti-reflection film is 350°C. Then, an electrode pattern was coated on the anti-reflection film by screen printing, and an aluminum electrode was coated on the reverse side of the surface of the semiconductor substrate on which the reflection layer was formed by screen printing, and the anti-reflection coating was carried out at ...

Embodiment 2

[0037] Made as figure 2 A solar cell with a passivation layer and an anti-reflection film is shown. At this time, as the semiconductor substrate, Cz mono 125×125cm was used 2 A p-type silicon substrate (0.5-2Ω) is used to form an n+ emission layer with 60Ω / sheet. Using Direct High Frequency (13.56MHz) PECVD, a silicon oxynitride passivation layer (refractive index: 1.65, thickness: 25nm) is formed on the above-mentioned emission layer, and a silicon nitride anti-reflection film (refractive index: 25nm) is formed on the above-mentioned passivation layer 1.90, thickness: 64nm). The deposition temperature of the above-mentioned passivation layer and anti-reflection film is 350°C. Then, an electrode pattern was coated on the anti-reflection film by screen printing, and an aluminum electrode was coated on the reverse side of the surface of the semiconductor substrate on which the reflection layer was formed by screen printing, and the anti-reflection coating was carried out at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com