Magnetic fixing device

A fixing device and magnetic force technology, which is applied in the field of magnetic fixing devices, can solve the problems that the magnetic unit does not report to the operation panel, and it is impossible to simply identify the adsorption state or non-adsorption state of multiple magnetic units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

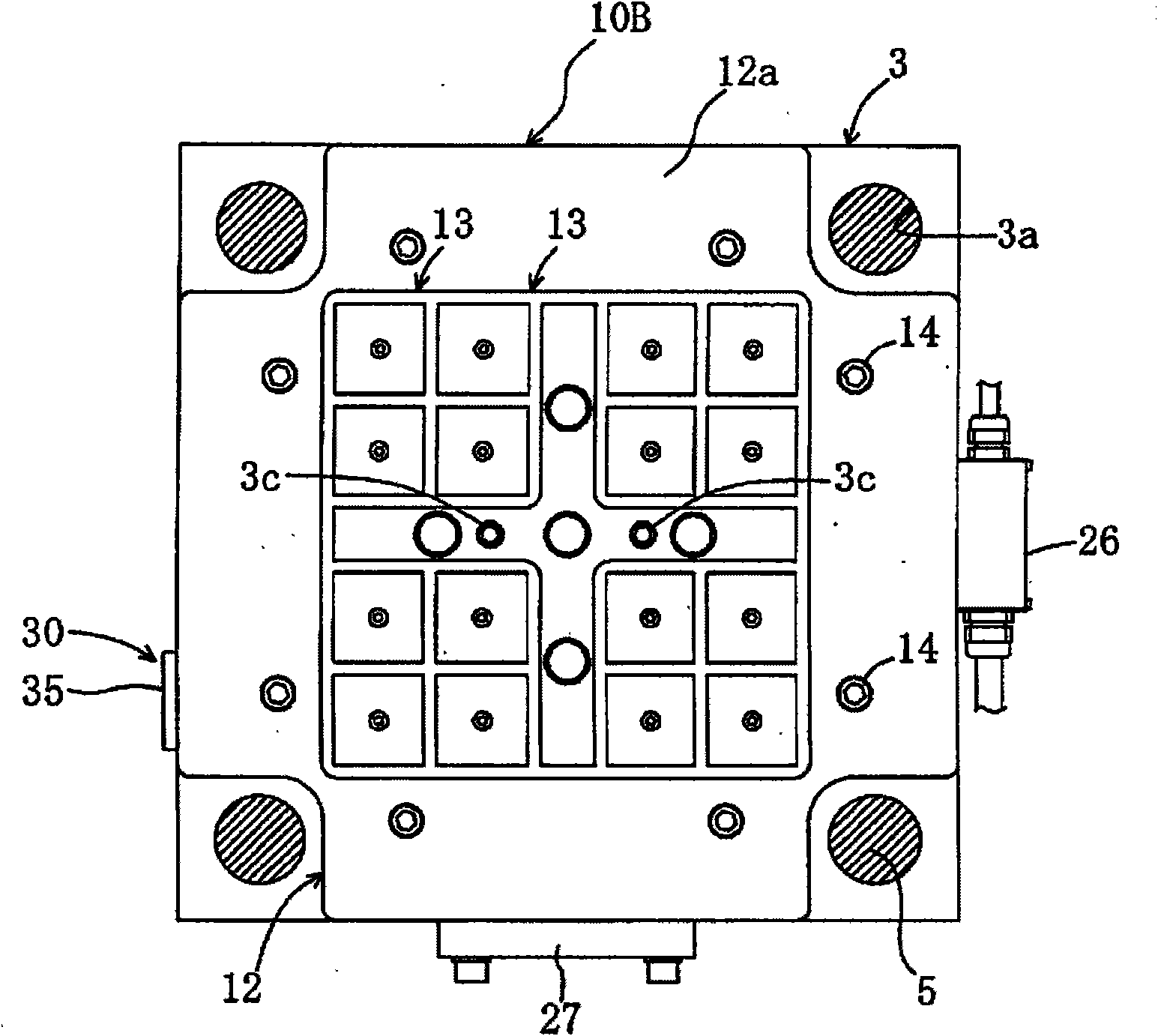

Embodiment 1

[0063] This embodiment is an example when the present invention is applied to an injection molding machine, so first, the injection molding machine 1 will be described. Such as figure 1 As shown, the injection molding machine 1 includes: a fixed side template 2 and a movable side template 3 facing each other, which are used to fix the mold M (the fixed side mold M1 and the movable side mold M2) as the clamping object; the template driving mechanism 4. It has a hydraulic cylinder (or drive motor), and is used to drive the template 3 close to / away from the template 2, so as to lock or open the mold M; four guide rods 5 guide the support template 3, so that Move freely in the approach / away direction; the injection mechanism 6 has an injection cylinder 6a, and the injection cylinder 6a injects molten synthetic resin into the mold cavity in the mold M in a mold-locked state; and an ejection mechanism 7, which will form The product is released from the mold M2.

[0064] When this ...

Embodiment 2

[0112] Next, the magnetic fastening devices 10A and 10B of the second embodiment will be described. However, the same reference numerals are assigned to the same configurations as in the first embodiment, and description thereof will be omitted. Instead of the actuation state display device 30 described above, an actuation state display device 50 is provided at the same position of the clamping plates 11 , 12 . The operating state display device 50 includes a display lamp 51 and a box member 52 for accommodating the display lamp 51 . The display lamp 51 outputs red light when the magnetic fixing devices 10A, 10B are in the adsorption state, and outputs green light when the magnetic fixing devices 10A, 10B are in the non-adsorption state. An operation control unit for operating and controlling the display lamp 51 is also provided.

Embodiment 3

[0114] Next, the magnetic force type fixing device 10C of the third embodiment will be described. However, the same reference numerals are assigned to the same constituent elements as those in Embodiment 1, and description thereof will be omitted. Such as Figure 18 As shown, the magnetic force type fixing device 10C is mounted and fixed on the platform of a comprehensive processing machine (machining center), for example, and utilizes magnetic force to attract and fix the workpiece pallet (clamping object), and the workpiece pallet is fixed with a Machined workpieces.

[0115]The magnetic fixing device 10C includes: a clamping plate 60 having a fixing surface 60a; a plurality of magnetic units 13 arranged on the clamping plate 60 and generating an adsorption force formed by magnetic force; and operating state display mechanisms 30E-30G , is provided on the front end portion (outer peripheral surface) of the clamping plate 60, and can display a mark indicating whether the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com