Method for packaging battery with polymer battery core sheathed by steel shell

A battery packaging and polymer technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of safety performance to be improved, complex battery packaging process, high battery cost, and achieve reliable battery safety performance, low battery cost, The effect of preventing force sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be explained in more detail below with reference to the accompanying drawings.

[0020] In the present invention, Figure 1 to Figure 6 It is a schematic explanation of each step of the present invention.

[0021] The invention provides a method for encapsulating a polymer battery cell with a steel shell, comprising the following steps:

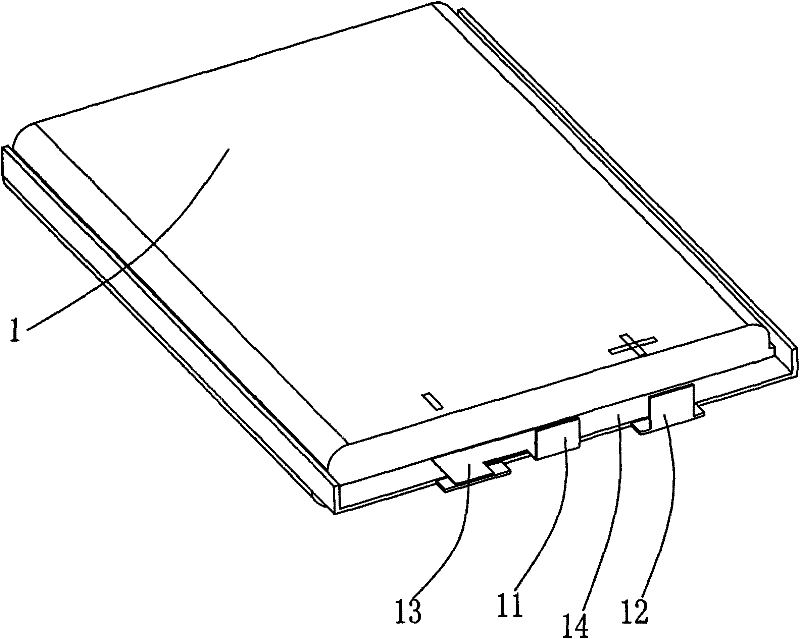

[0022] 1. On the basis of the positive electrode 12 and the negative electrode 11 of the existing cell, a nickel sheet (14, 13) is welded, and the non-welded parts of the positive electrode 12 of the cell 1 and the nickel sheets 14 and 13 of the negative electrode 11 are insulated with high temperature. tape around the insulation, leaving the welded part (see figure 1 );

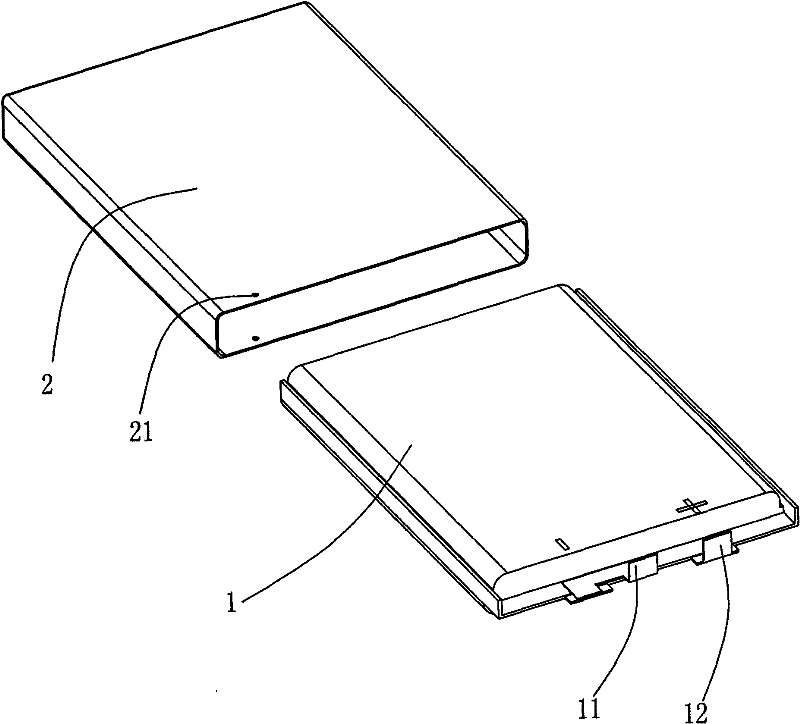

[0023] 2. Put the cell 1 into the thin-walled steel shell 2, and inject an appropriate amount of silica gel to fix the cell 1 (see figure 2 );

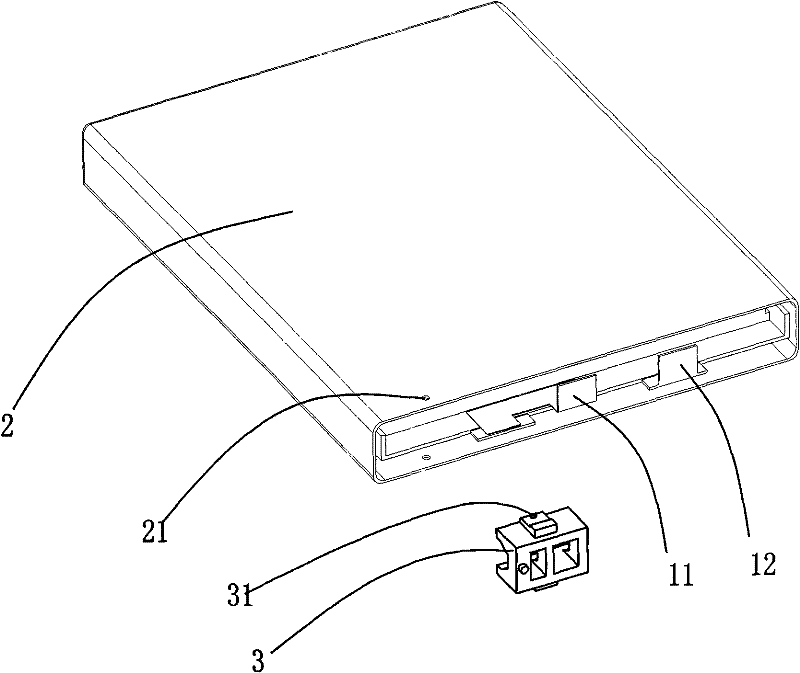

[0024] 3. Using the PCB bracket positioning hole 21 on the thin-walled steel shell 2 as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com