Active vibration isolation control platform

An active vibration isolation and control platform technology, which is applied in mechanical vibration control, non-electric variable control, comprehensive factory control, etc., can solve the problems of low control accuracy, complex auxiliary equipment, small deformation, etc., to overcome large volume, The effect of simple structure and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

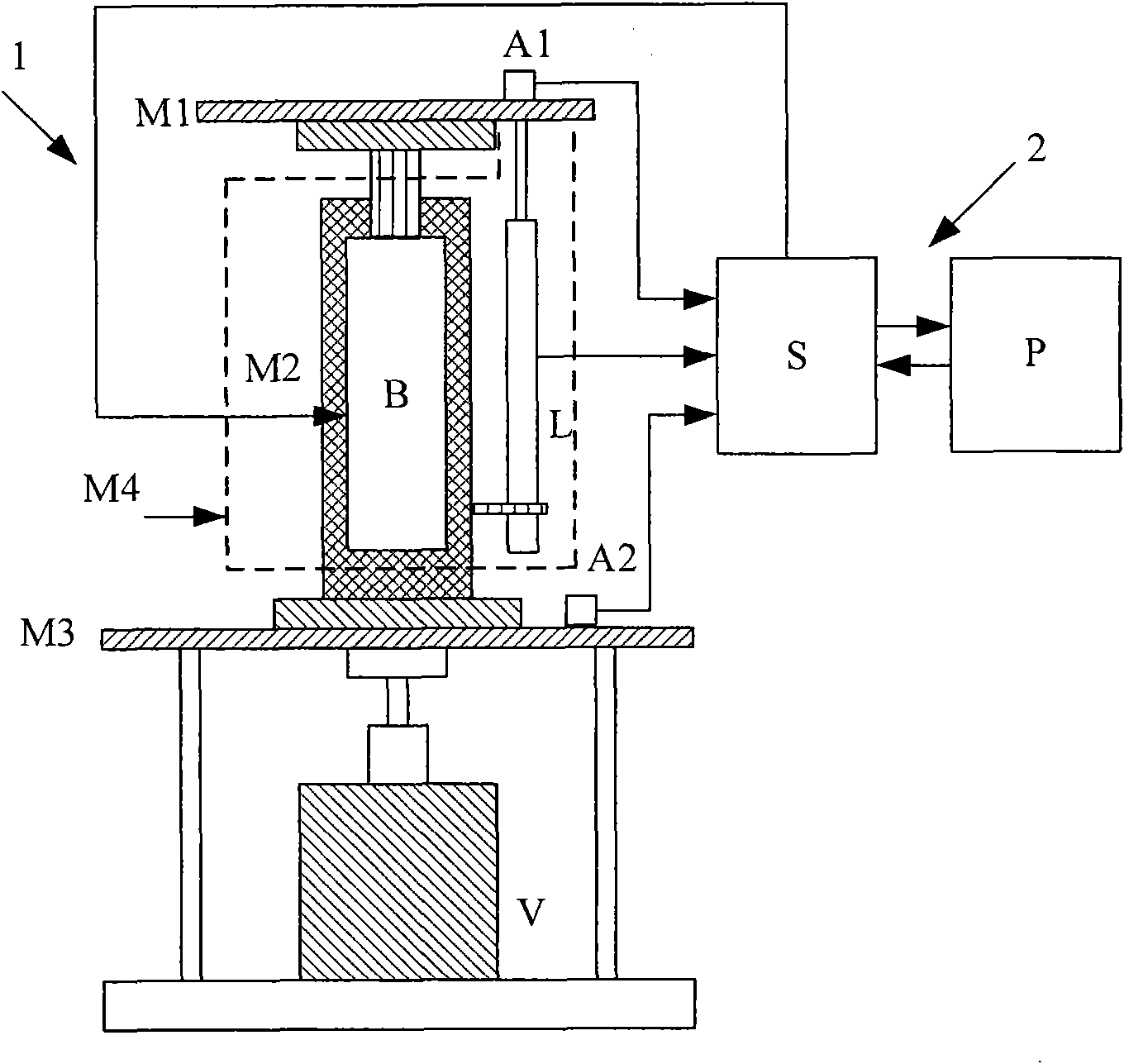

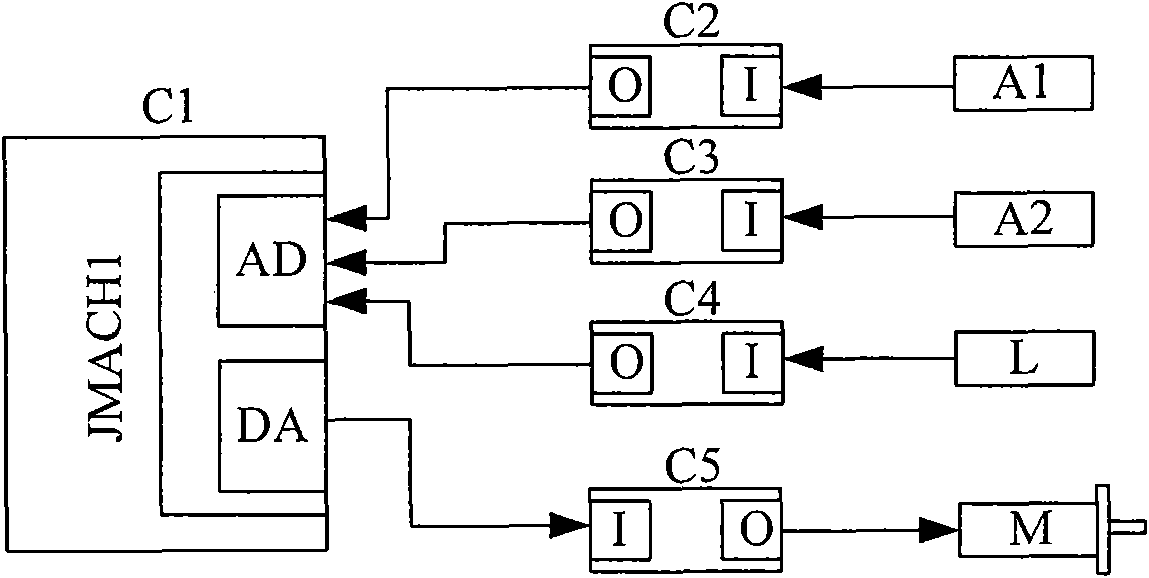

[0022] Such as figure 1 It is shown in the configuration connection diagram of the active vibration isolation control platform based on the voice coil motor, which includes: active vibration isolation device 1 and active vibration isolation controller 2, which are electrically connected; the active vibration isolation controller 2 After receiving the state information of the active vibration isolation device 1 , the active vibration isolation controller 2 calculates and obtains a command to control the active vibration isolation device 1 by using an active vibration control algorithm.

[0023] The active vibration control algorithm adopts an approximate self-adaptive dynamic programming method based on a neural network, without establishing an accurate dynamic model of the vibration isolation device, and by measuring the input and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com